Manufacturing method of hollow ring member

The technology of a ring member and manufacturing method, which is applied in the field of manufacturing, can solve problems such as large welding deformation, and achieve the effects of reducing welding deformation, avoiding internal stress, and increasing rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Now, specific embodiments of the present invention will be described in detail with reference to the accompanying drawings.

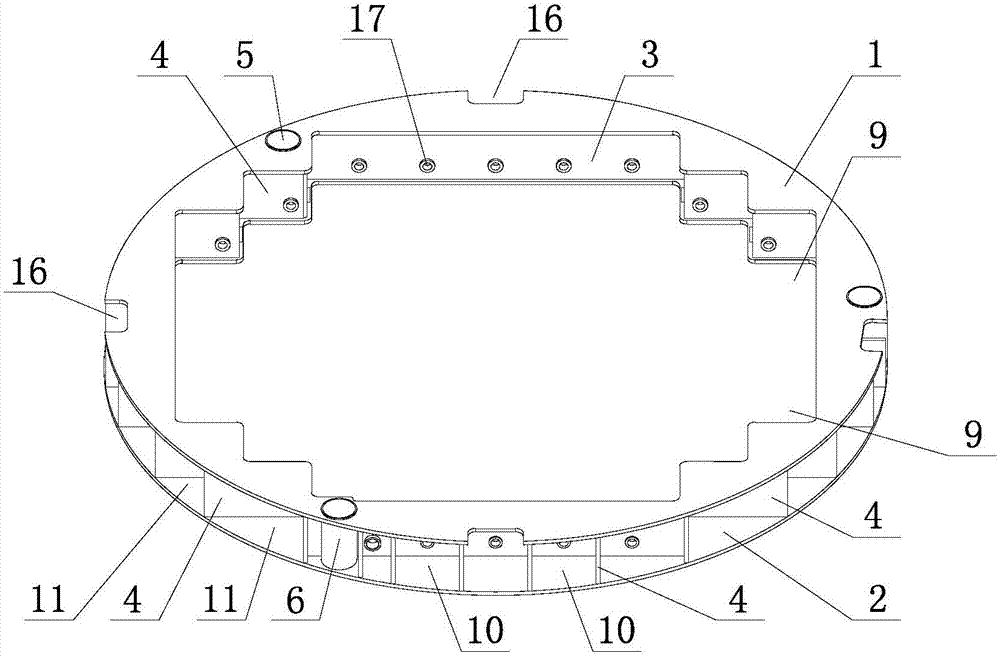

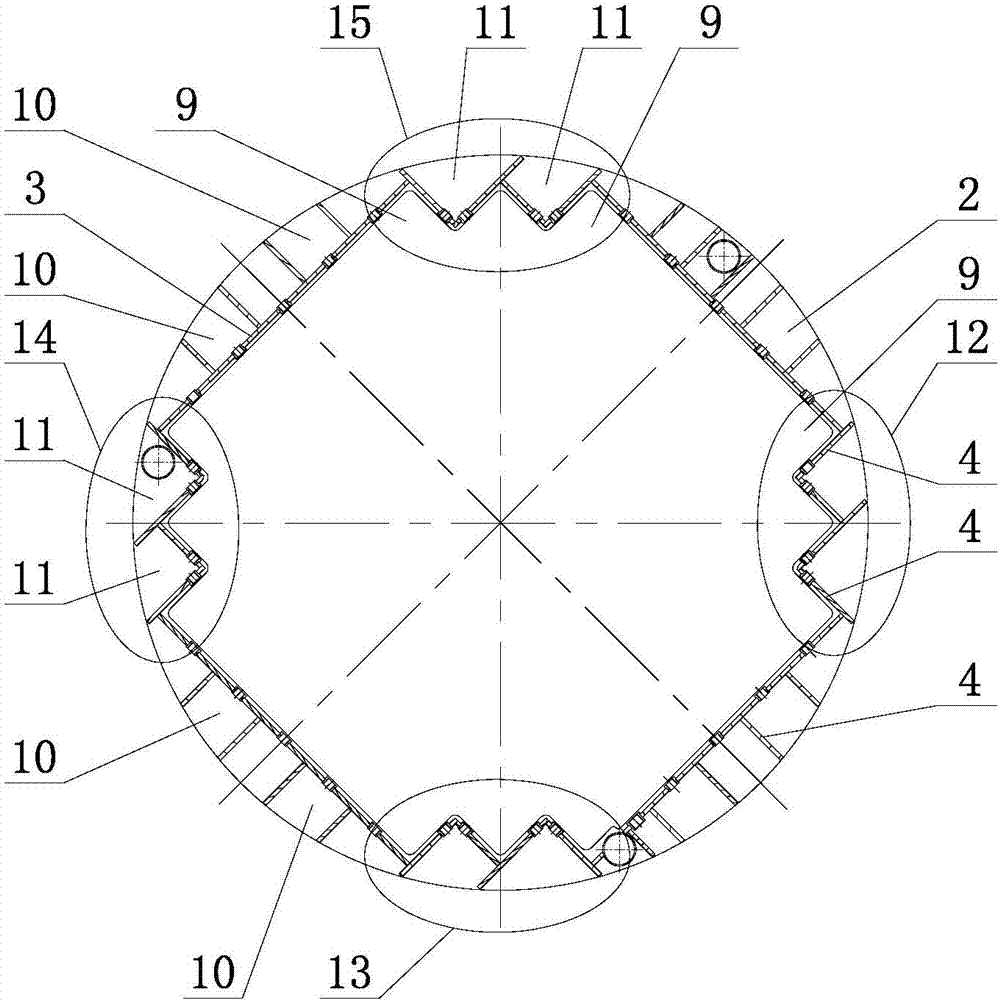

[0027] Such as figure 1 and figure 2 The hollow annular member shown has a top plate 1 and a bottom plate 2, the top plate 1 and the bottom plate 2 are basically the same in structure, and both are disc-shaped. They are parallel to each other and the top plate 1 is located directly above the bottom plate 2 , the difference is that the top plate 1 is uniformly provided with four notches 16 along its circumference.

[0028] In the middle of the top plate 1 and the bottom plate 2, an inner panel 3 and a reinforcing plate 4 are vertically provided. There are four inner panels 3, which are evenly distributed along the circumference of the top plate 1 and the bottom plate 2; the reinforcing plate 4 is used to fix the top plate 1 , Base plate 2 and inner panel 3. Threaded sleeves 17 are provided on the inner panel 3 and part of the reinforcing plate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com