Plastic cutting machine

A cutting machine, plastic technology, applied in the direction of metal processing, etc., can solve the problems of personal injury, unsafe, easy to generate dust, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

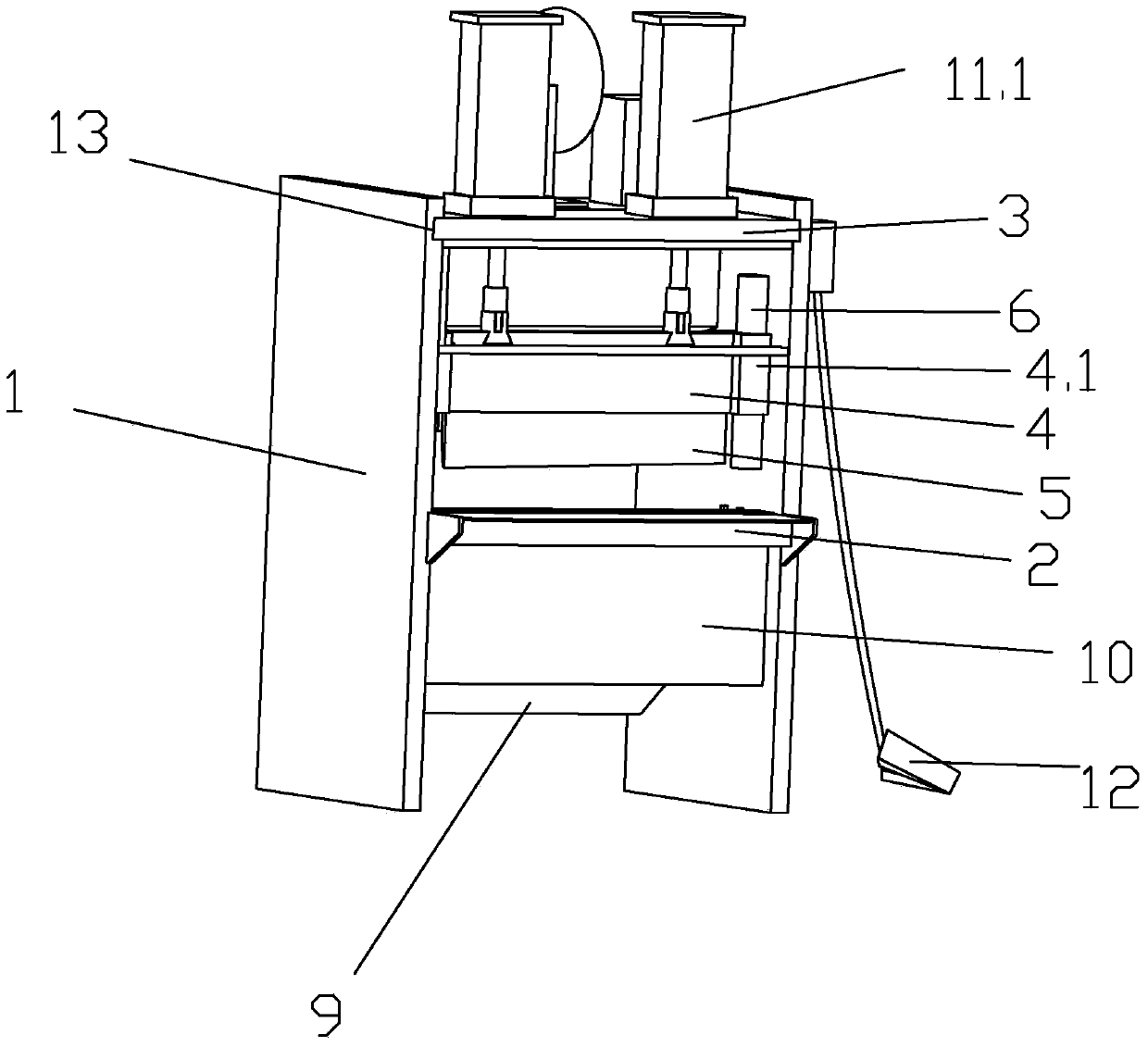

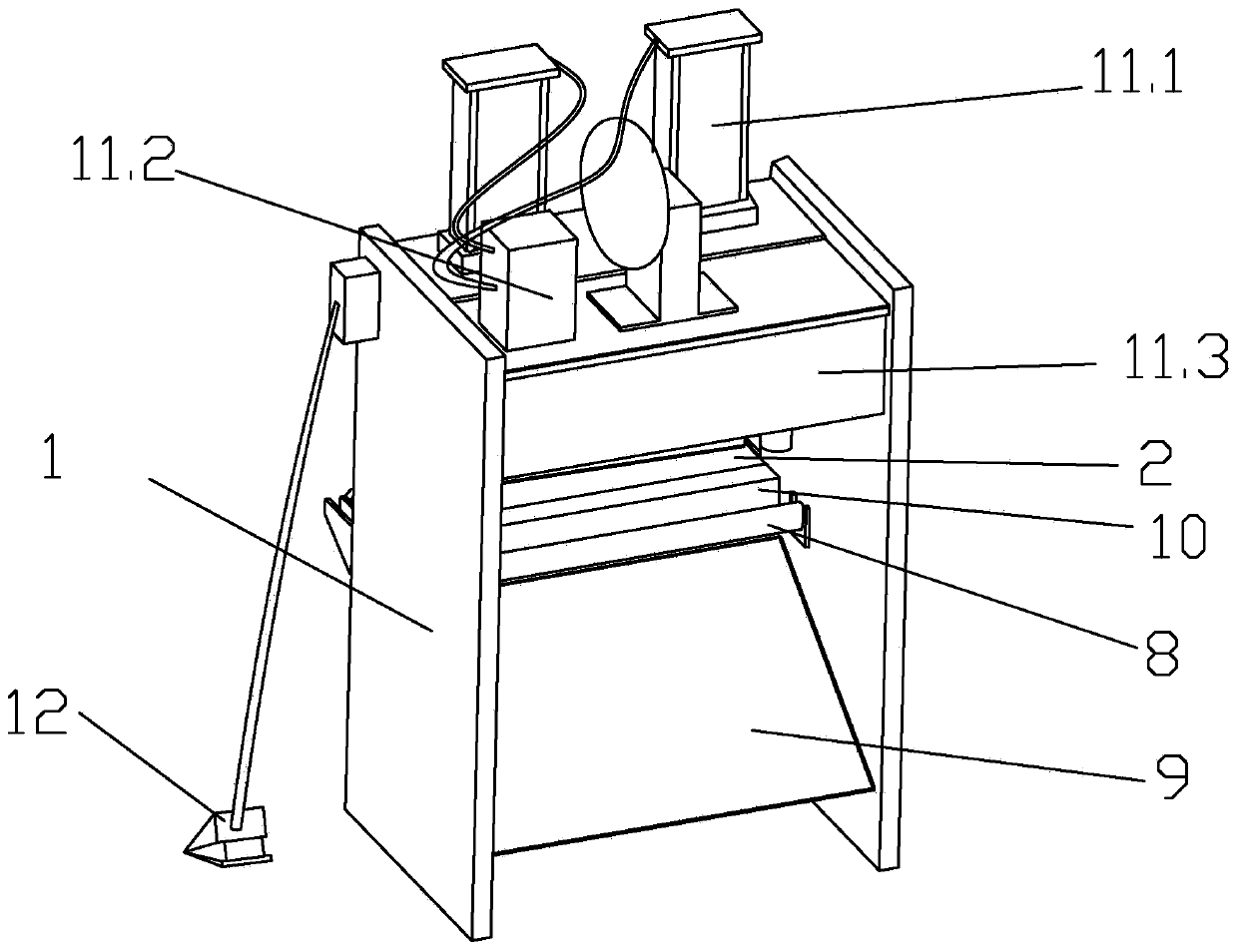

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

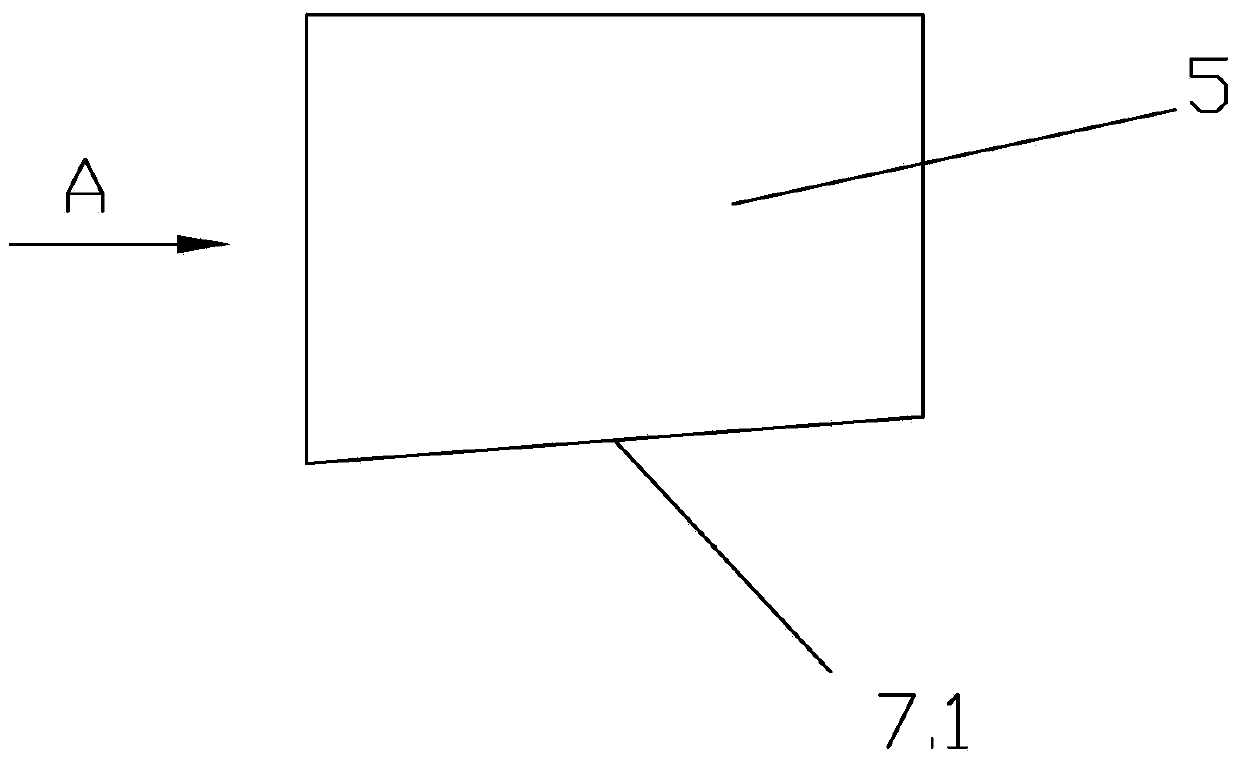

[0021] Such as figure 1 , figure 2 , image 3 , Figure 4 Shown, a kind of plastic cutting machine, it comprises cutting machine main body 1, and described cutting machine main body 1 middle part is provided with cutting table 2, and cutting machine main body 1 upper part is provided with support plate 3, and described support plate 3 is installed with pressing down mechanism, the lower end of the pressing mechanism is fixedly connected with a knife rest 4, the lower end of the knife rest 4 is provided with a blade 5, the blade 5 is located above the cutting table 2, and a safety control switch is provided outside the main body 1 of the cutting machine.

[0022] The plastic cutting machine cuts large plastic products through the blade 5, which does not generate dust and is more environmentally friendly; the main body 1 of the cutting machine is provided with a safe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com