Method for manufacturing mobile phone casing with concave side wall and structure thereof

A mobile phone shell and shell system technology, which is applied to the structure of telephones, etc., can solve problems such as difficulty in demoulding, restrictions on appearance design, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to enable your examiner to have a further understanding and understanding of the purpose, features and effects of the present invention, the following detailed description with the accompanying drawings is as follows.

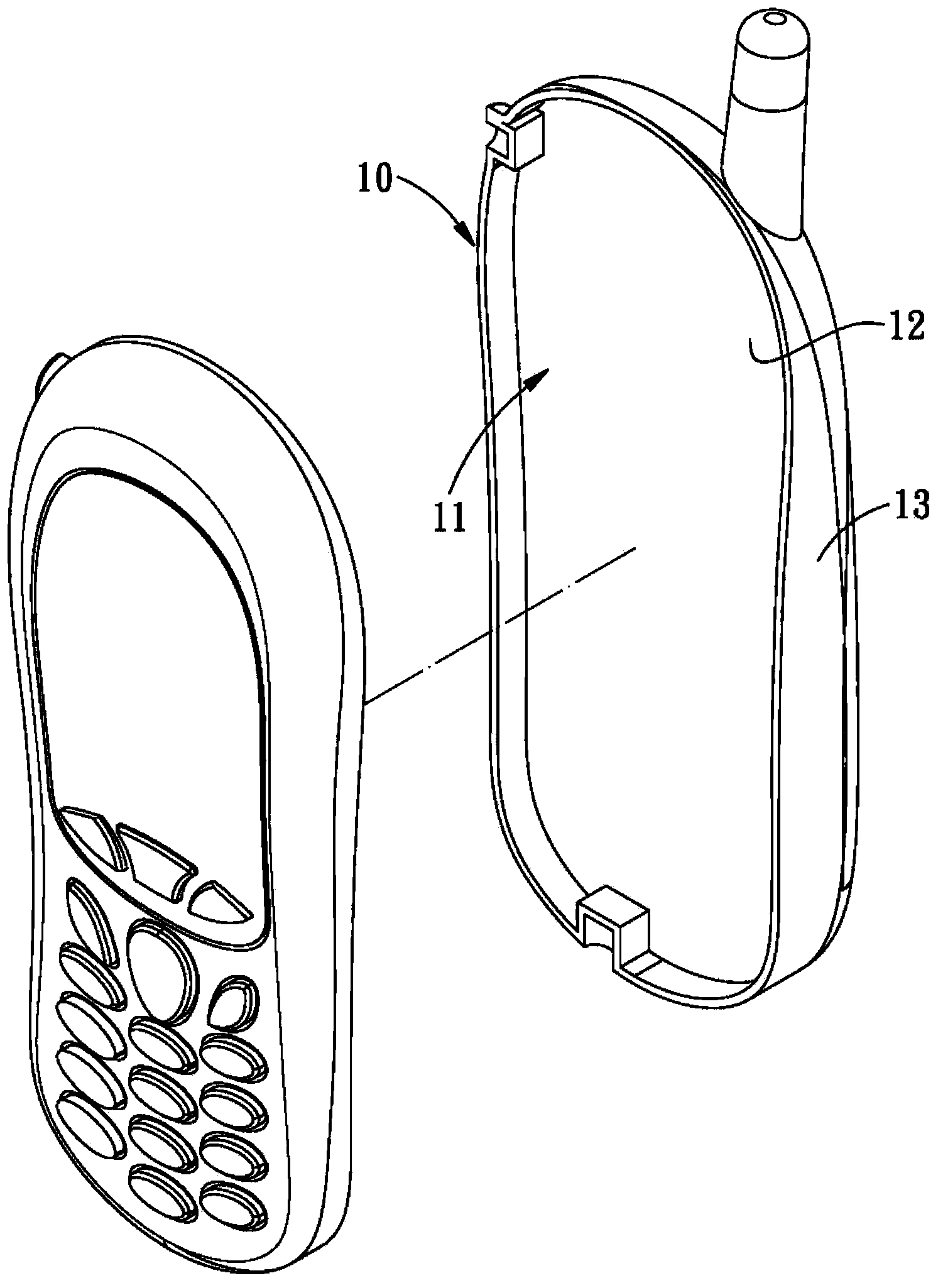

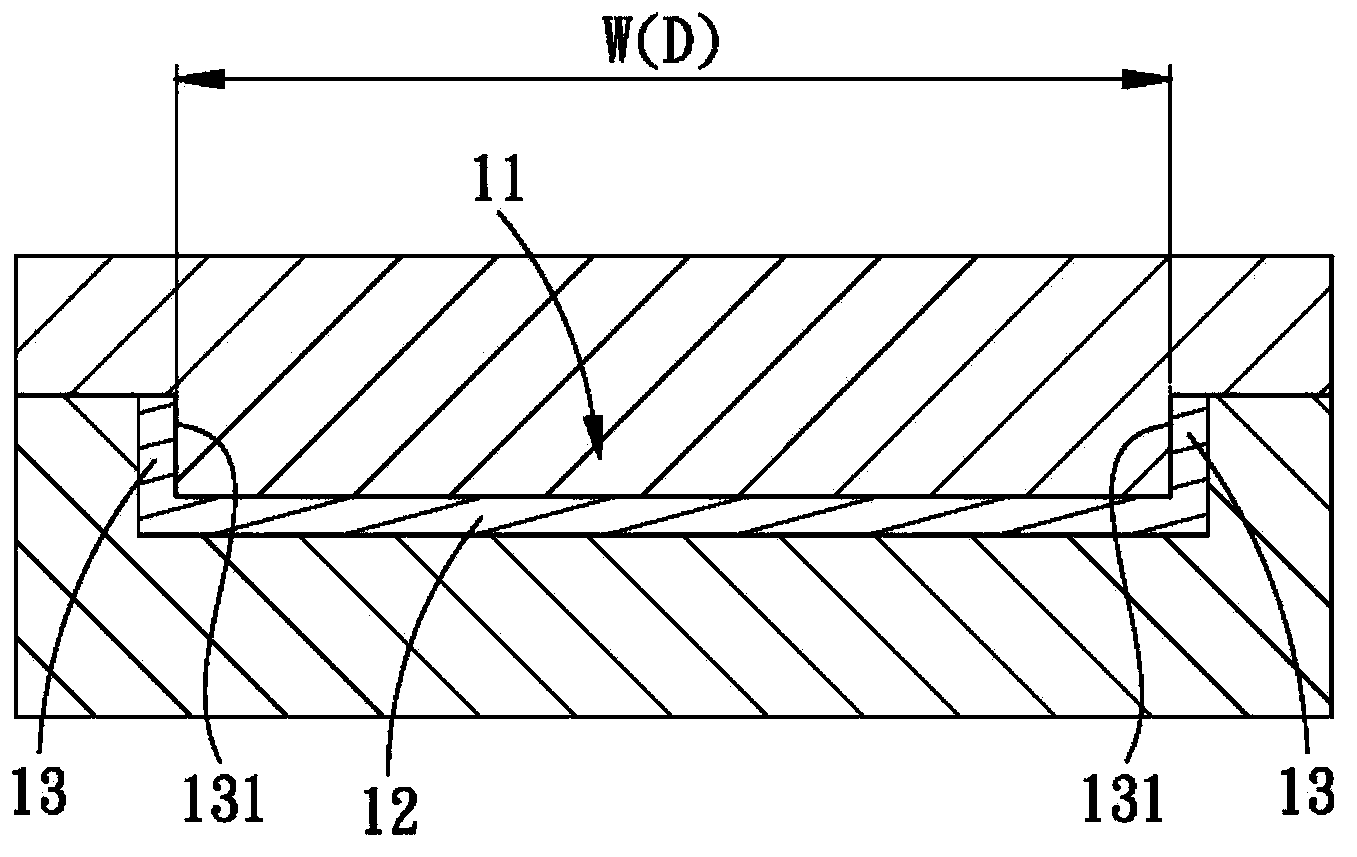

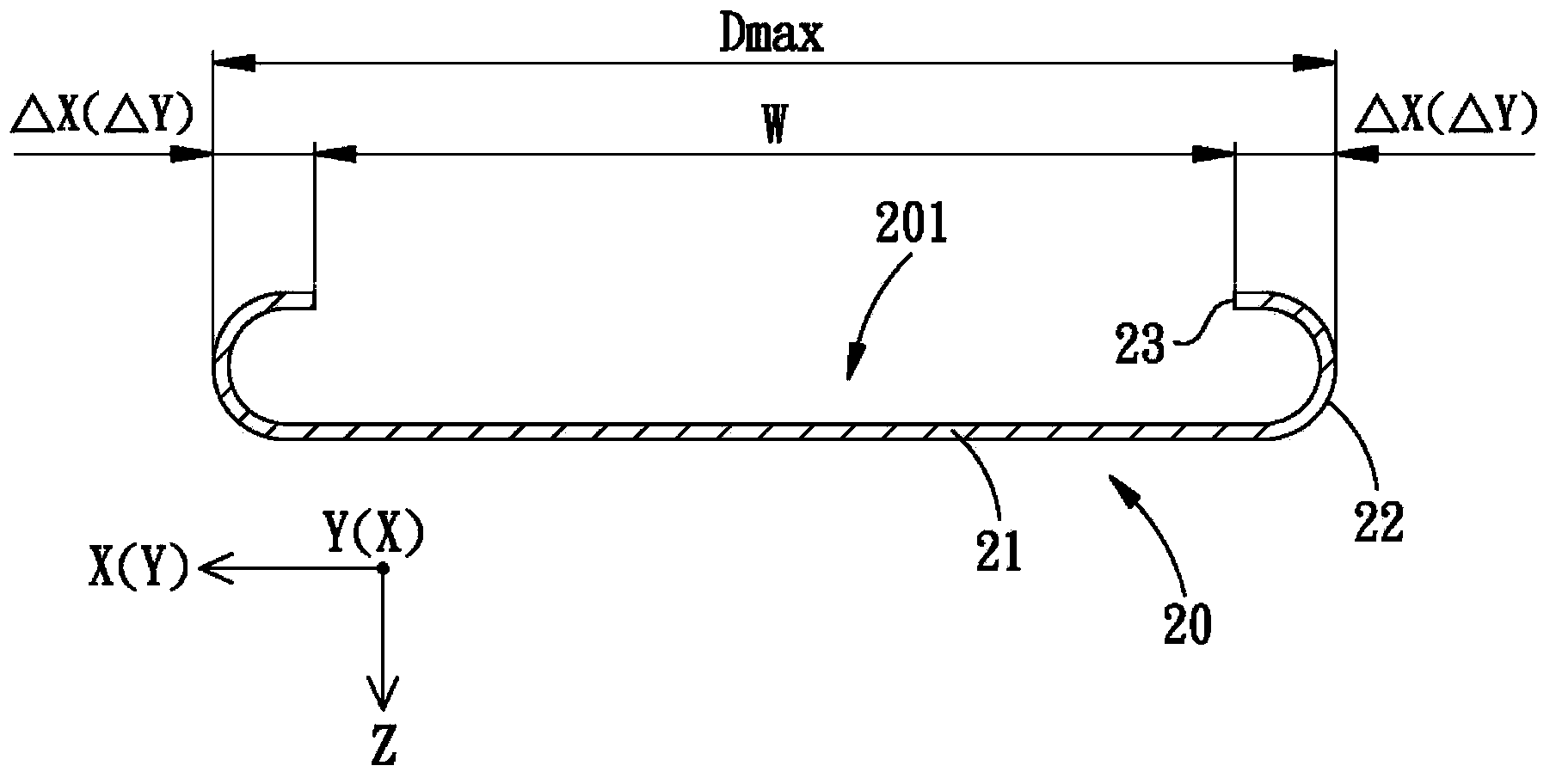

[0050] First, please image 3 , Figure 4 Cooperate Figure 5-8 As shown, the present invention provides a preferred embodiment of a method for manufacturing a mobile phone housing with concave side walls. The manufacturing method is mainly for forming a side wall 22 of a mobile phone housing 20 into a concave structure. The manufacturing steps include (a) Outer mold manufacturing step S1, (b) Inner mold manufacturing step S2, (c) impregnated fiber layer inserting step S3, (d) heating molding step S4, and (e) demolding step S5, wherein:

[0051] (a) Outer mold manufacturing step S1: such as Figure 5 As shown, a hard block is used to recess a mold cavity 31, which defines the recessed direction of the mold cavity 31 as a Z direction, and a bottom sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com