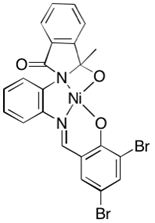

Method for catalyzing glycolide polymerization with asymmetric aluminum complex containing o-phenylenediamine group

A technology of o-phenylenediamine and aluminum complexes, applied in the fields of compounds containing group 3/13 elements of the periodic table, chemical instruments and methods, organic chemistry, etc., can solve the problems of non-renewability and non-degradability, etc. Achieve the effects of various catalyst structures, high stereoselectivity, and controllable molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

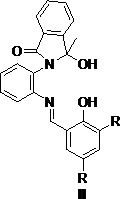

[0042] The structural formula of the synthesized ligand is the above formula (A), where R is hydrogen, and the reaction process is as follows: add 0.40 g of unilaterally protected o-phenylenediamine (a) and an equimolar amount of salicylaldehyde into 20 mL of methanol, and heat to reflux After 12 hours of reaction, after the reaction was completed, it was cooled and filtered, washed with cold methanol, filtered, collected, dried and weighed to obtain 0.50 g of solid, with a yield of 87.7%.

[0043] The product obtained is characterized, and the results are as follows:

[0044] 1 H NMR (400 MHz, CDCl 3 ) δ 12.86 (s, 1H, O H ), 8.42 (s, 1H, Ar H C=N),7.85 (m, 2H, Ar– H ), 7.64 (d, J = 7.0 Hz, 1H, Ar– H ), 7.56 (m, 1H, Ar– H ), 7.44(m, 3H, Ar– H ), 7.32 (m, 2H, Ar– H ), 6.96 (m, 4H, Ar– H ).

[0045] HRESI-MS: m / z cacld.C 21 h 14 N 2 o 3 [M-H] - ; 341.0926, found: 341.0924.

[0046] It can be seen from the above characterization results that the obtained produ...

Embodiment 2

[0048] The structural formula of the synthesized ligand is the above formula (A), where R is a methyl group, and the reaction process is as follows: 0.30 g of unilaterally protected o-phenylenediamine (a) and an equimolar amount of 3,5-dimethyl salicylaldehyde Add 20 mL of methanol, heat to reflux for 12 hours, cool and filter after the reaction, wash with cold methanol, filter, collect, dry and weigh to obtain 0.40 g of solid, with a yield of 85.1%.

[0049] The product obtained is characterized, and the results are as follows:

[0050] 1 H NMR (400 MHz, CDCl 3 ) δ 12.72 (s, 1H, O H ), 8.40 (s, 1H, Ar H C=N),7.80 (m, 2H, Ar– H ), 7.66 (m, 2H, Ar– H ), 7.15 (m, 3H, Ar– H ), 6.92 (s, 1H, Ar– H ), 2.15 (s, 3H, ArC H 3 ), 2.04 (s, 3H, ArC H 3 ). HRESI-MS: m / z ccld. C 23 h 18 N 2 o 3 [M-H] - ; 369.1238, found: 369.1238.

[0051] It can be seen from the above characterization results that the obtained product is the ligand in which R is a methyl group in the above...

Embodiment 3

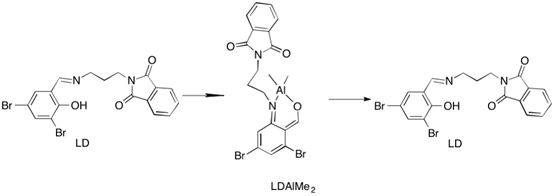

[0053] The structural formula of the synthesized ligand is the above formula (A), where R is bromine, and the reaction process is as follows: add 0.35 g of unilaterally protected o-phenylenediamine (a) and 3,5-dibromosalicylaldehyde in 20 In mL methanol, heated to reflux for 12 hours, after the reaction was completed, cooled and filtered and washed with cold methanol, filtered, collected, dried and weighed to obtain 0.66 g of solid, with a yield of 90.4%.

[0054] The product obtained is characterized, and the results are as follows:

[0055] 1 H NMR (400 MHz, CDCl 3 ) δ 12.64 (s, 1H, O H ), 8.344 (s, 1H, Ar H C=N),7.86 (d, J = 7.2 Hz, 1H, Ar– H ), 7.68 (m, 3H, Ar– H ), 7.42 (m, 2H, Ar– H ), 7.36(m, 1H, Ar– H ), 7.10 (m, 3H, Ar– H ).

[0056] HRESI-MS: m / z cacld.C 21 h 12 Br 2 N 2 o 3 [M-H] - ; 496.9134, found: 496.9136.

[0057] It can be seen from the above characterization results that the obtained product is the ligand in which R is bromine in the above f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com