Cracking-resistant radiation-resistant polymer film of glass

An anti-cracking and film-attaching technology, applied in the direction of layered products, chemical instruments and methods, metal layered products, etc., can solve the problems of broken glass, easy to break, single function of the film, etc., and achieve the effect of avoiding radiation

Inactive Publication Date: 2013-12-04

李晓春

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] With the rapid development of glass technology and the diversification of glass performance, glass has become one of the most common materials around us. As we all know, glass is a relatively fragile substance. Be careful during transportation or installation, otherwise it is easy to cause damage. The broken glass will hurt people. In order to change the fragile characteristics of the glass and increase the toughness of the glass, we can paste a film on the surface of the glass to achieve the effect. The ordinary film has a single function and is easy to break, which cannot meet the requirements.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

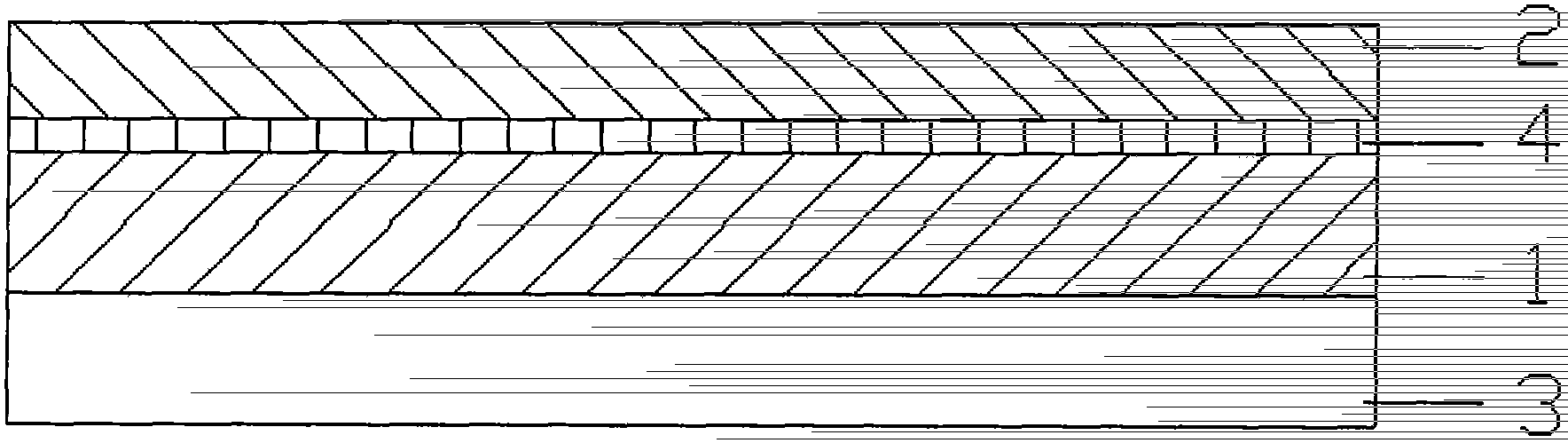

[0014] see figure 1 , the anti-cracking and radiation-free film for glass of the present invention, which includes an adhesive layer 1 and a protective layer 3, is characterized in that: an anti-crack layer 2 is arranged between the adhesive layer 1 and the protective layer 3, and the anti-crack layer 2 is a net shaped metal layer. And a wave-absorbing layer 4 is arranged between the protective layer 3 and the anti-crack layer 2 .

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a cracking-resistant radiation-resistant polymer film of glass. The cracking-resistant radiation-resistant polymer film of glass comprises a glue layer (1) and a protective layer (3). An anticracking layer (2) is arranged between the glue layer (1) and the protective layer (3). The anticracking layer (2) is a netted metal layer. A wave-absorbing layer (4) is arranged between the protective layer (3) and the anticracking layer (2). The anticracking layer (2) is arranged between the glue layer (1) and the protective layer (3) and the anticracking layer (2) is the netted metal layer. Through a tension force and hardness of the netted metal layer, glass protection is realized and the glass with the cracking-resistant radiation-resistant polymer film is broken difficultly so that the anticracking effects are obtained. The cracking-resistant radiation-resistant polymer film can effectively absorb indoor radiated wave and transform the indoor radiated wave into heat.

Description

(1) Technical field [0001] The invention relates to a polymer film. (2) Background technology [0002] With the rapid development of glass technology and the diversification of glass performance, glass has become one of the most common materials around us. As we all know, glass is a relatively fragile substance. Be careful during transportation or installation, otherwise it is easy to cause damage. The broken glass will hurt people. In order to change the fragile characteristics of the glass and increase the toughness of the glass, we can paste a film on the surface of the glass to achieve the effect. The ordinary film has a single function and is easy to break, which cannot meet the requirements. (3) Contents of the invention [0003] The object of the present invention is to overcome the above disadvantages and provide a glass anti-crack radiation-free film. [0004] The object of the present invention is achieved in this way: a kind of anti-cracking radiation-free film...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B32B15/04B32B33/00

Inventor 李晓春

Owner 李晓春

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com