Wood shrinkage tightness closer

A wood-tight technology, applied in friction-clamped detachable fasteners, connecting components, mechanical equipment, etc., to solve problems such as loss of hoop effect, bulging or falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

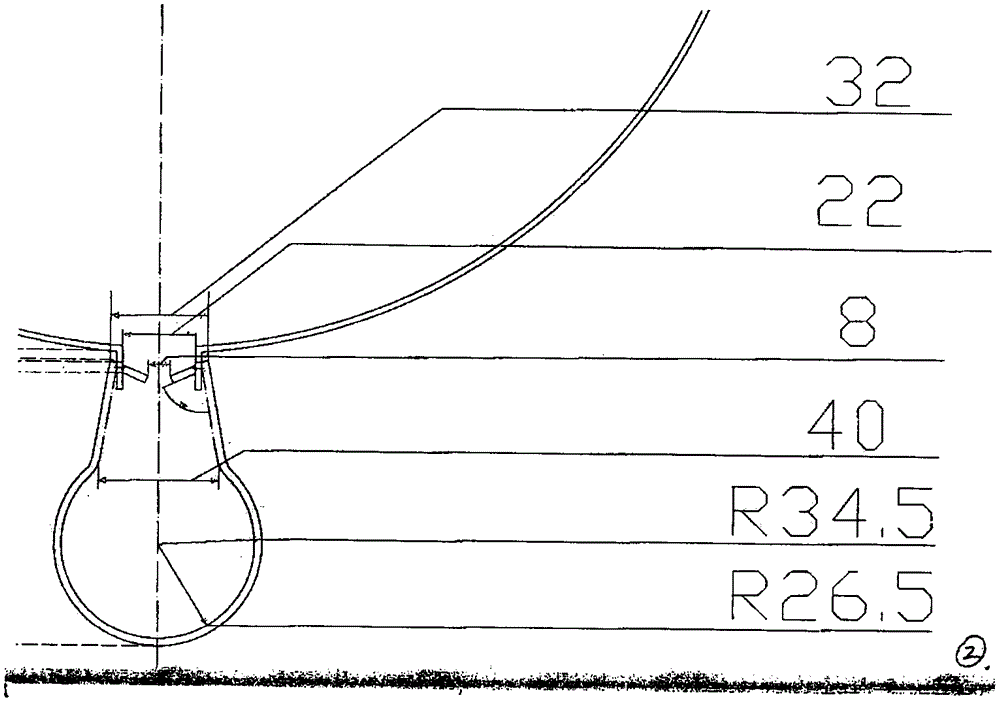

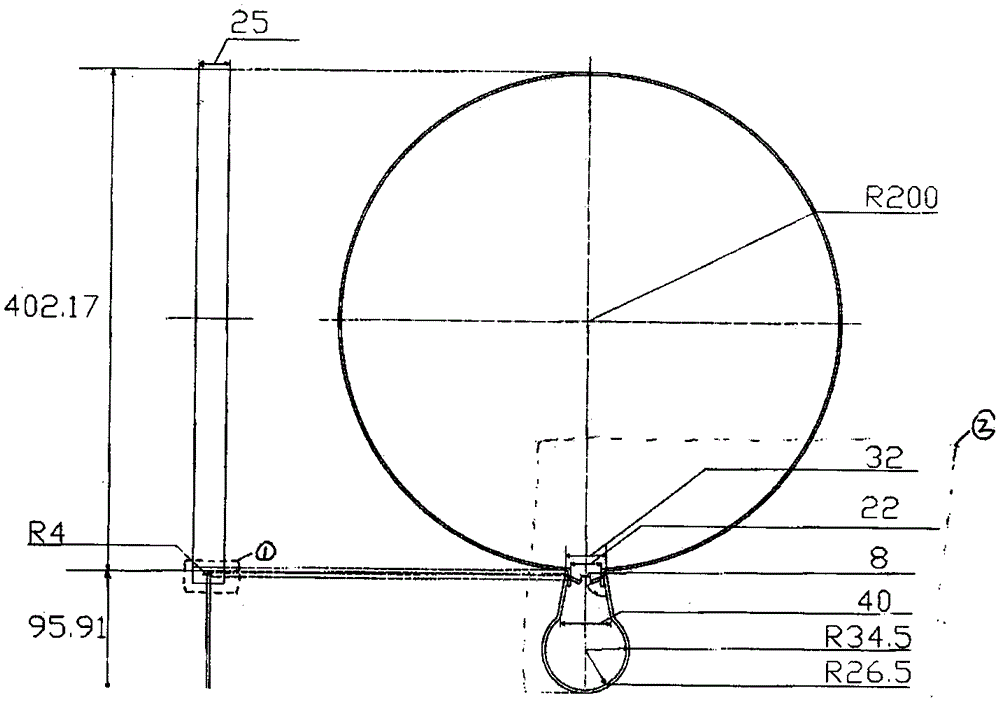

[0009] My household chopping board is made of Jian wood, with a diameter of 35 cm and a thickness of 6 cm. The diameter of the hoop is 35 cm, the width is 3 cm, and the thickness is 2MM. 5 years old and still in perfect condition.

[0010] Several relatives and friends have also used this method to add such an accelerometer to their chopping boards for 3-5 years, and the effect is still very good.

[0011] Especially in the timber station, the log with a length of more than ten to twenty meters is used at both ends and in the middle, which also achieves the effect of preventing cracking. At this time, the width and thickness of the adapter can be smaller.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com