Corrugated steel web bridge stepped construction technology

A technology of corrugated steel webs and construction technology, which is applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of hidden safety hazards of the bottom plate, difficulty in finding support points for the roof, etc., shorten the construction period, avoid shortage of personnel, and save costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

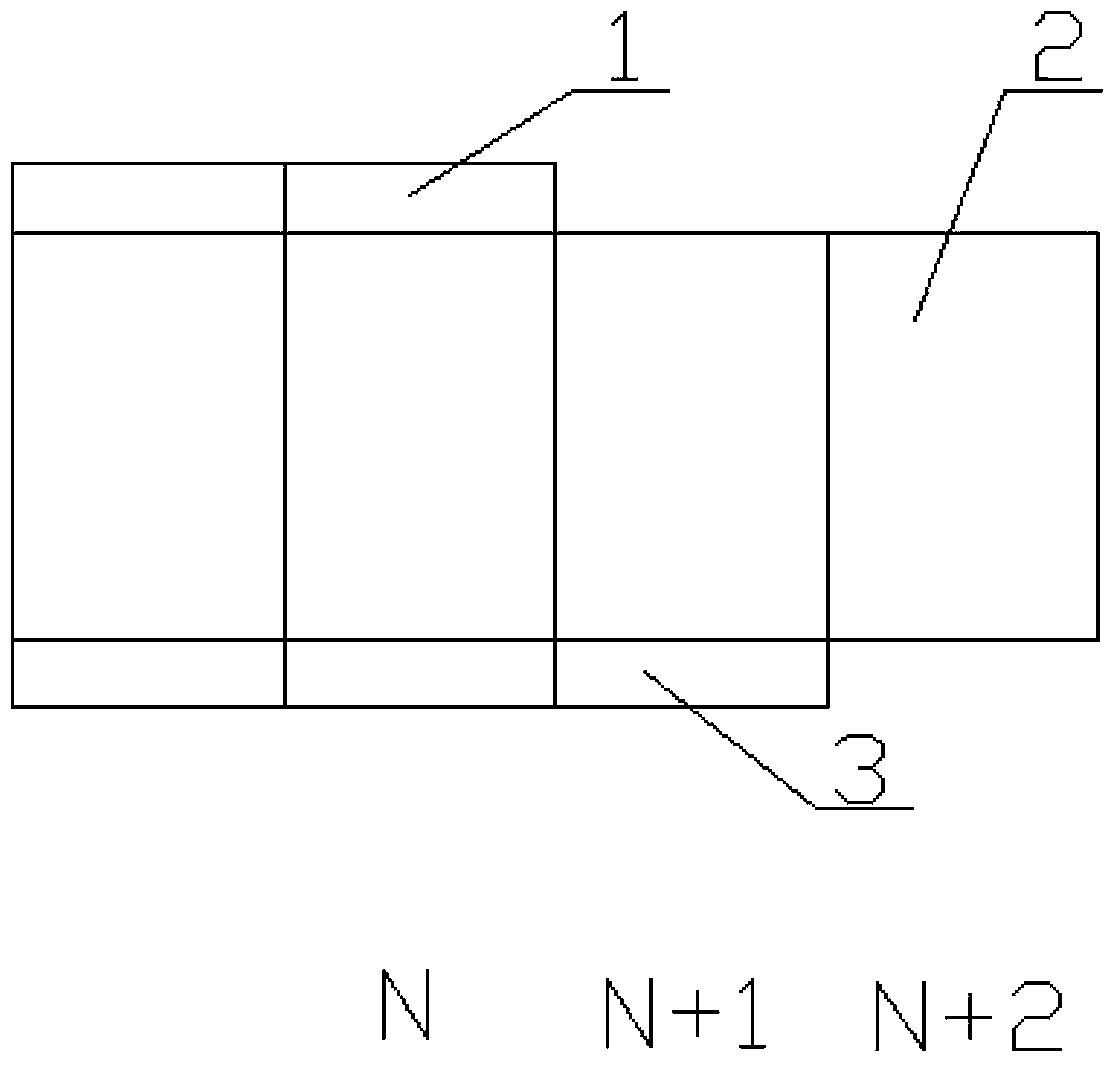

[0024] The stepped construction technology of the corrugated steel web bridge is divided into N sections, N+1 sections, and N+2 sections according to the sequence of construction sections along the longitudinal direction of the bridge. The steel web 2 is located between the top plate 1 and the bottom plate 3, and works in three sections: 1. Construction of the top plate 1 in the N section, construction of the bottom plate 3 in the N+1 section; 2. Installation of the corrugated steel web 2 in the N+2 section ; 3. After the above-mentioned three sections are completed, each enters the next section in turn;

[0025] Only one construction work is carried out at the same time in the vertical space where each segment is located.

[0026] Each step works independently within each segment.

[0027] In the three-section operation method, the installation section of the corrugated steel web 2 is one section ahead of the bottom plate 3, and the installation section of the corrugated ste...

Embodiment 2

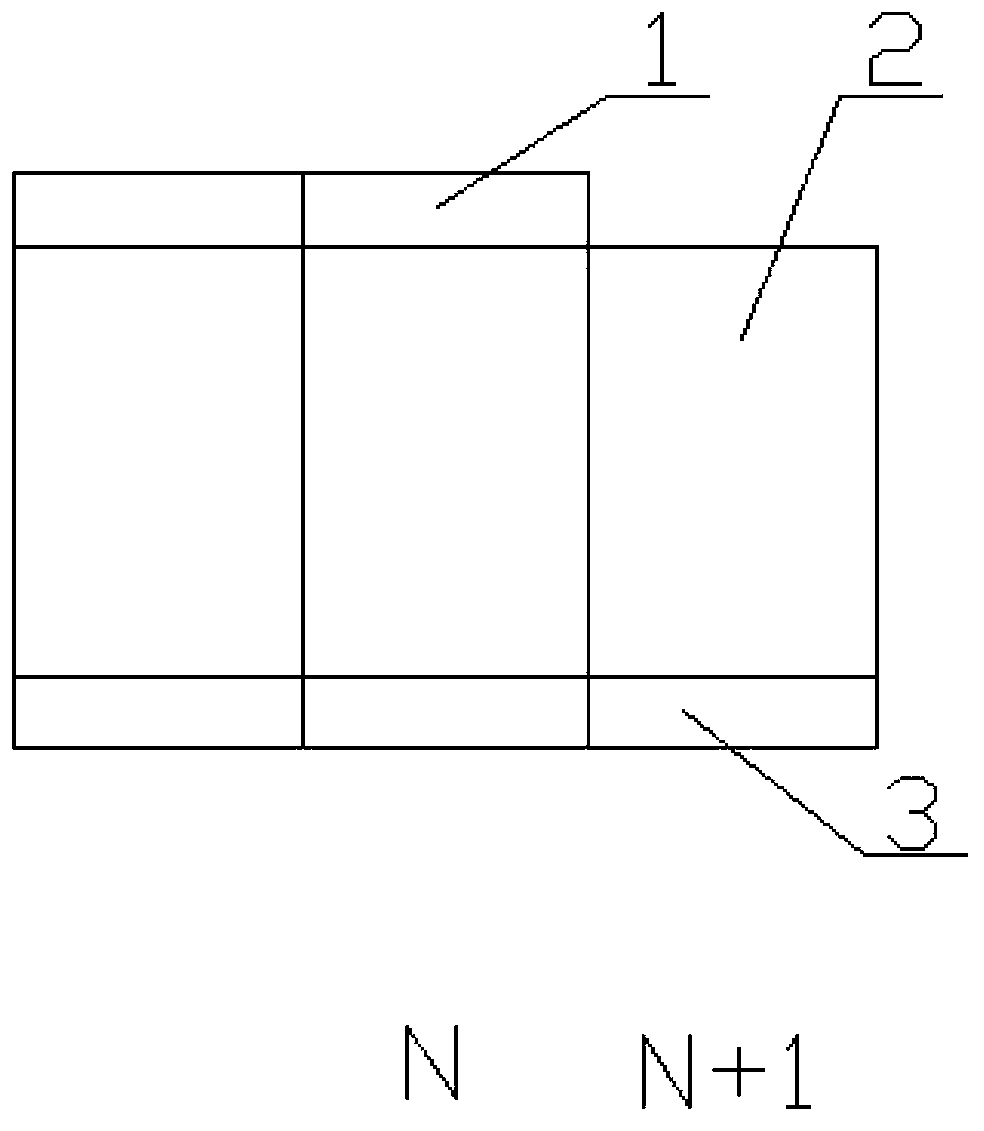

[0033] The stepped construction technology of the corrugated steel web bridge is divided into N sections, N+1 sections, and N+2 sections according to the sequence of construction sections along the longitudinal direction of the bridge. The steel web 2 is located between the top plate 1 and the bottom plate 3, two sections work: a. N section constructs the top plate 1, N+1 section first installs the corrugated steel web 2, and then constructs the N+1 section bottom plate 3, b . After the above two segment operations are completed, each enters the next segment in turn.

[0034] Only one construction work is carried out at the same time in the vertical space where each segment is located.

[0035] Except for step a, each section in the remaining steps works independently.

[0036] In the two-section operation method: the installation section of the corrugated steel web 2 and the bottom plate 3 are located in the same section, and the installation section of the corrugated steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com