Superimposed pile self-reflexive force balance load box

A self-reflexive, superimposed technology, applied in the test of infrastructure, construction, infrastructure engineering, etc., can solve the problems of low construction efficiency, high consumption, low transportation efficiency, etc., to ensure authenticity and effectiveness, The effect of reducing the bottom area and facilitating grouting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

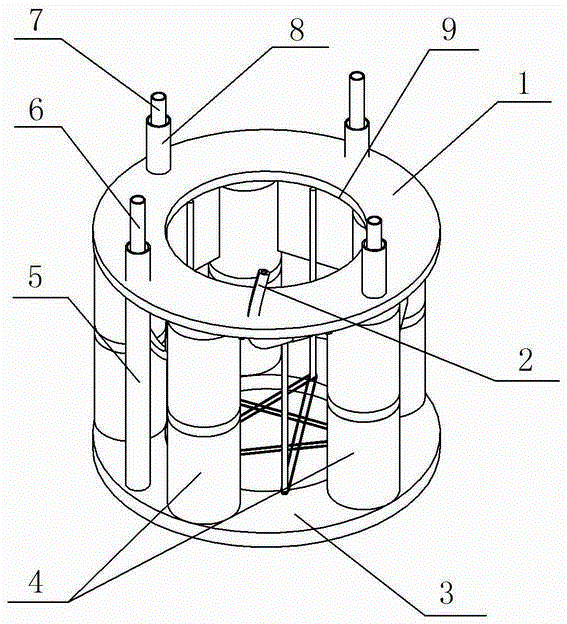

[0008] A superimposed pile body self-reflexive force balance load box, including an upper plate 1, a lower plate 3, and a hydraulic cylinder 4. The upper plate 1 and the lower plate 3 have a coaxial central hole 9, and the hydraulic cylinder 4 is symmetrically and evenly installed on the upper plate. 1 and the lower plate 3, the hydraulic oil cylinder 4 is connected in series through the inlet and outlet oil pipe 2, and is connected with the oil inlet valve and the oil return valve of the hydraulic station. Each hydraulic oil cylinder 4 is equipped with two upper and lower pistons, and the lower piston The top supports the bottom of the upper piston, and a through hole is opened in the center of the lower piston. The upper displacement rod 7 is welded on the upper plate 1 and sleeved with the upper sheath tube 8. The lower displacement rod 6 is welded on the lower plate 3 and passes through the upper plate 1. The lower sheath pipe 5 is sheathed on the lower displacement rod 6 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com