Mining dump truck power shift gearbox

A technology for mining dump trucks and gearboxes, which is applied to transmissions, transmission parts, gear transmissions, etc., can solve the problems of multiple transmission routes and complexity of gearbox parts, and achieve simple switching, effective power transmission, and gears The effect of reduced number of engagements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

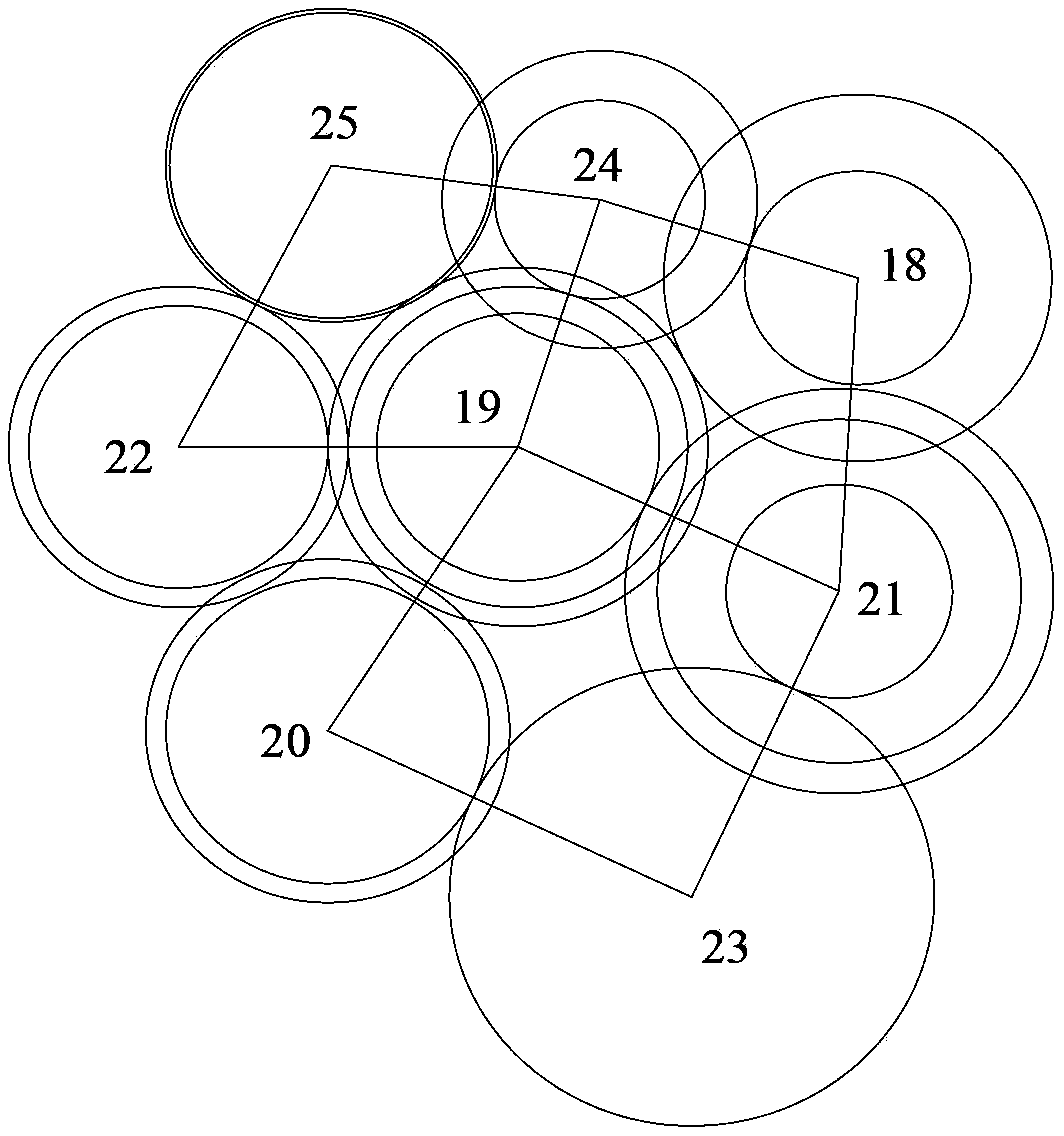

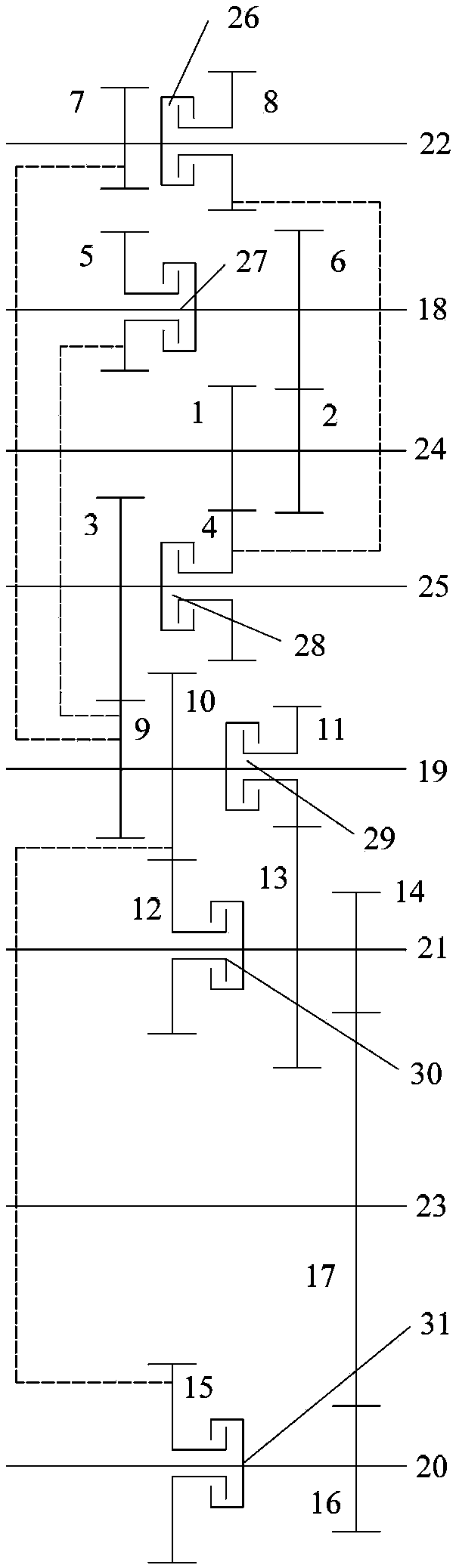

[0012] like figure 1 , 2 Shown, the mining dump truck power shift gearbox of the present invention mainly consists of an input shaft 24, an output shaft 23, and the intermediate shaft includes a first intermediate shaft 25, a second intermediate shaft 18, and a third intermediate shaft 19 , the fourth intermediate shaft 20, the fifth intermediate shaft 21, the sixth intermediate shaft 22, and clutches 26, 27, 28, 29, 30, 31, which are set in one-to-one correspondence with the six intermediate shafts; Gear 1 and gear 2 are respectively provided on 24, gear 3 and gear 4 are respectively provided on the first intermediate shaft 25, and gear 5 and gear 6 are respectively provided on the second intermediate shaft 18. A gear 9, a gear 10 and a gear 11 are respectively provided on the third intermediate shaft 19, a gear 15 and a gear 16 are respectively provided on the fourth intermediate shaft 20, and a gear 12 is respectively provided on the fifth intermediate shaft 21. , gear 13...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap