Magnetic steel pushing-in device

A technology of propulsion device and magnetic steel, which is applied in the manufacture of stator/rotor body, etc., can solve the problems of low efficiency, time-consuming, cumbersome methods, etc., and achieve the effect of improving work efficiency and efficient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to enable those skilled in the art to better understand the present invention, specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

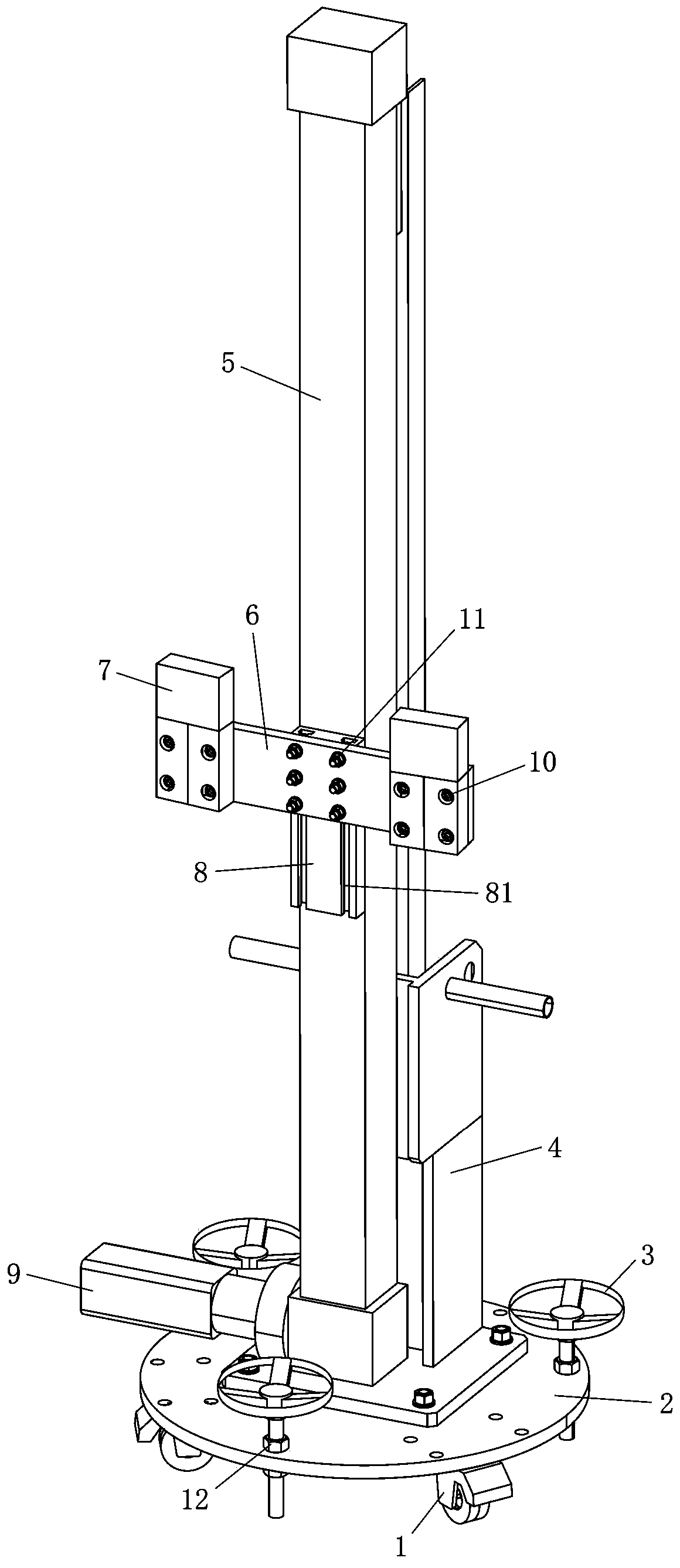

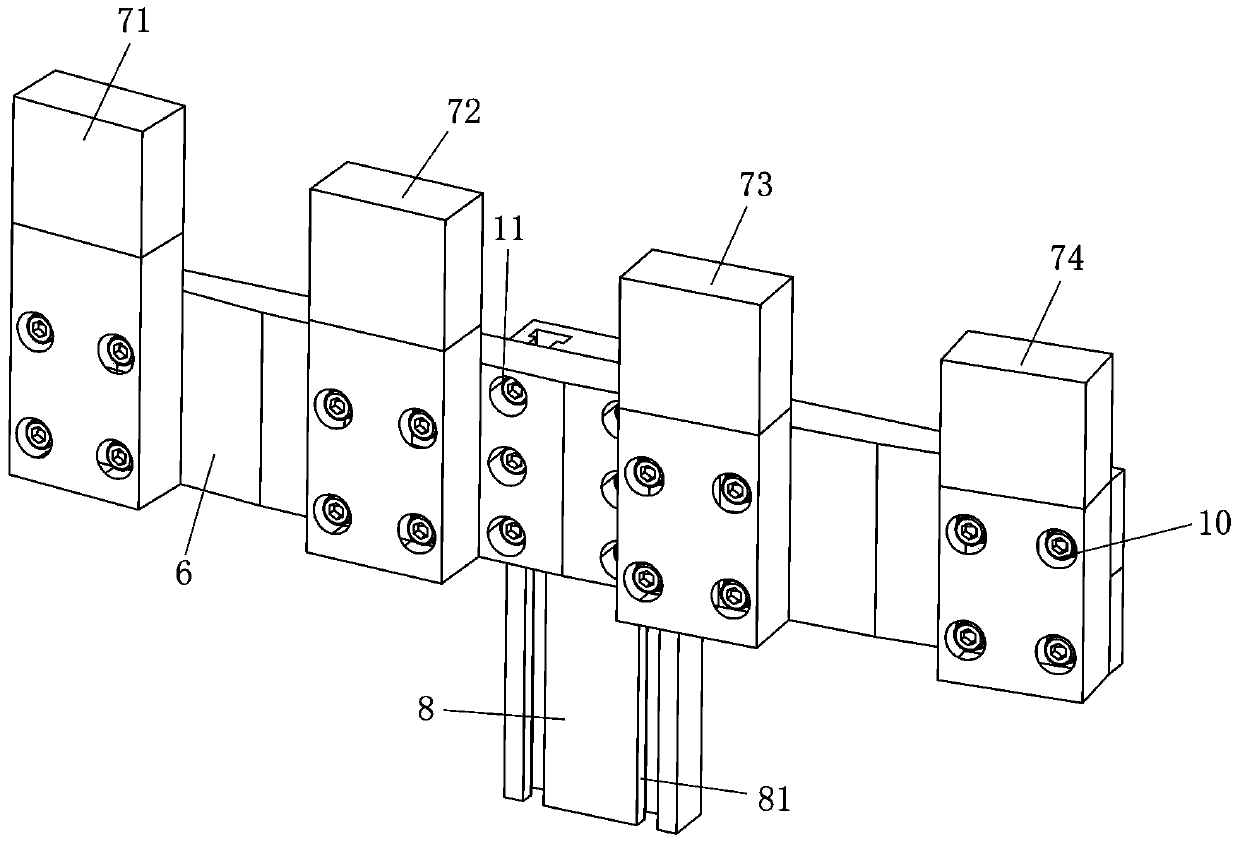

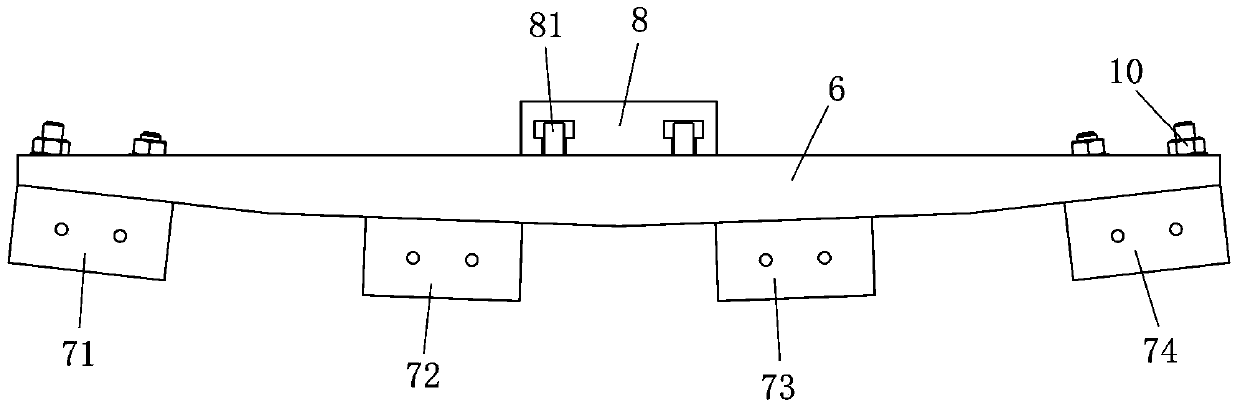

[0023] refer to figure 1 , figure 1 is a structural schematic diagram of a magnetic steel pushing device according to an embodiment of the present invention.

[0024] According to an embodiment of the present invention, a magnet steel pushing device for installing a magnet on a yoke is provided. Several rows of cavities are formed on the cylindrical yoke vertically or at a small inclination angle to the vertical direction, the size of the cavities can ensure that the magnetic steel is smoothly pushed into it from bottom to top And the magnets are stuck in the cavity without moving in the circumferential direction, that is, the magnets in the cavity only have the freedom of moving up and down, and the number of magnets pushed into the cavity depends on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com