Adjustable front bumper treading mechanism for truck

A front bumper and adjustable technology, which is applied to the arrangement, transportation and packaging of vehicle parts, pedals or ladders, etc., can solve the problems of high stepping height, unsafety, and inconvenient boarding of personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

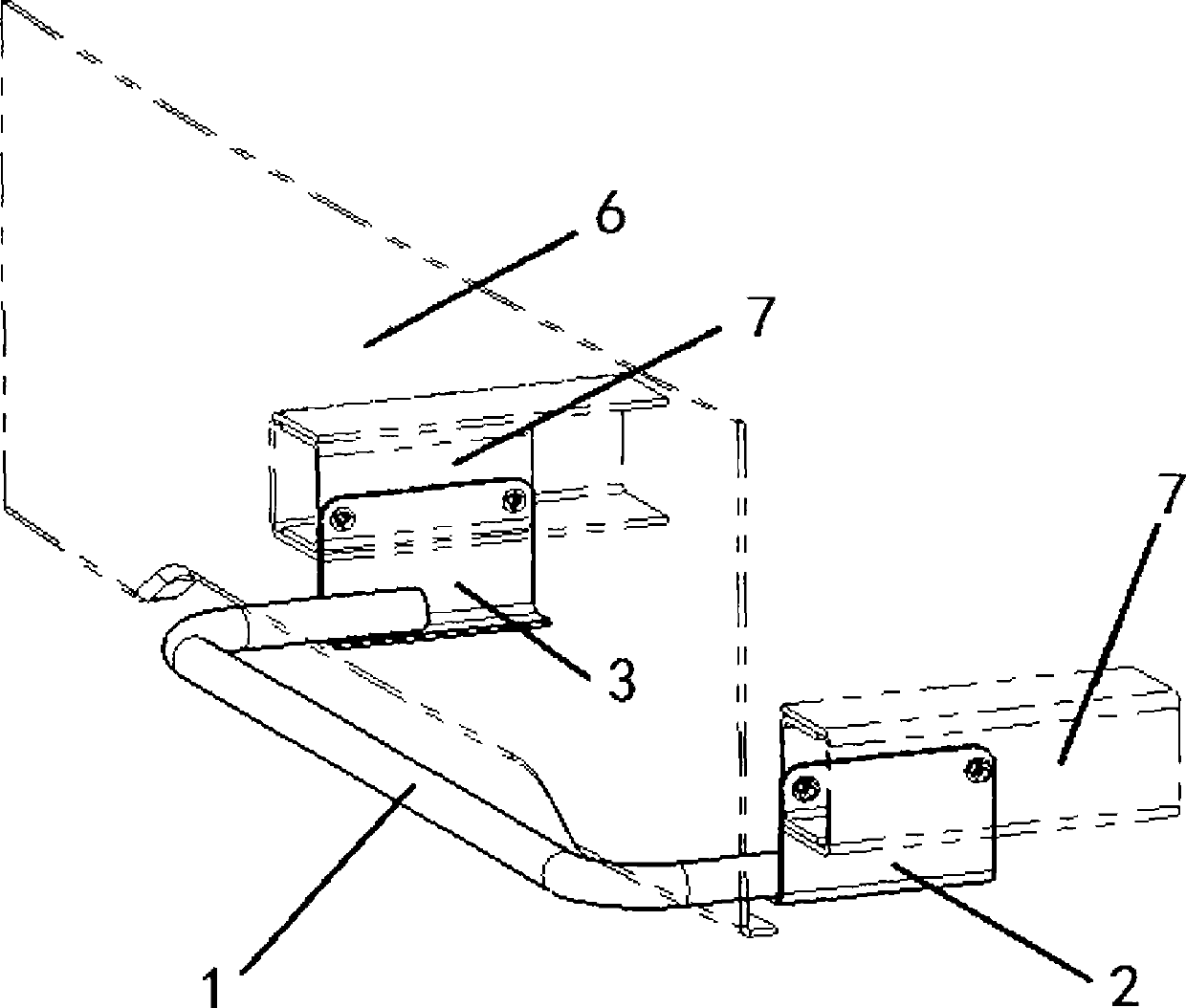

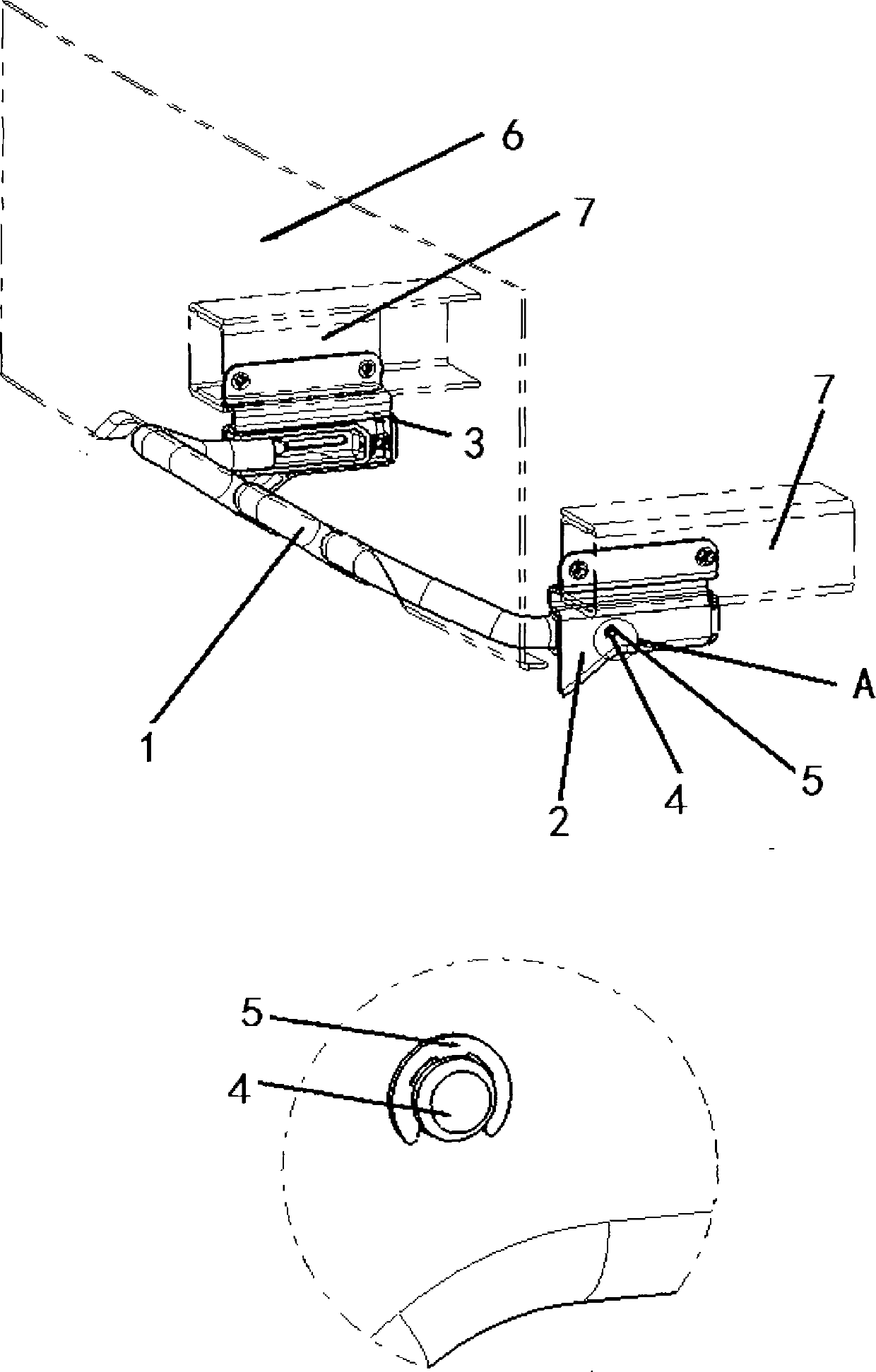

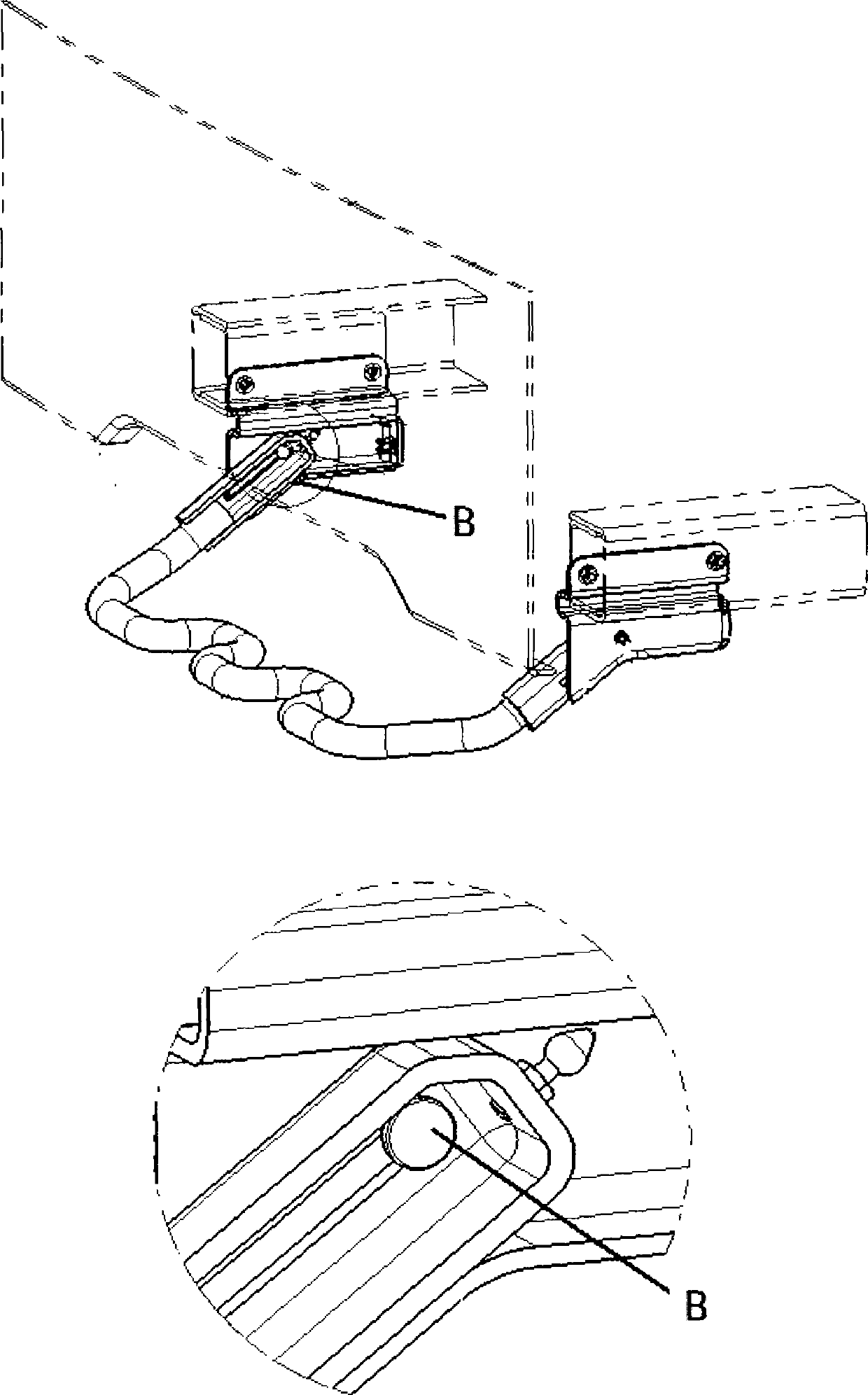

[0023] as attached Figure 2-6 As shown, this embodiment relates to an adjustable front bumper step mechanism for trucks, including a tube beam assembly 1 , and a left bracket assembly 2 and a right bracket assembly 3 arranged symmetrically. The tube beam assembly includes a tube beam 11, which has an "S-bend" part 18 for stepping on, and the two ends of the tube beam have a left connecting bracket 12 and a right connecting bracket 15 welded to the two ends of the tube beam; The beam assembly 1 also includes a left ball stud 14, which is screwed into the threaded hole at the end of the left connecting bracket 12; the left bracket assembly 2 includes a main mounting surface 21, a side mounting surface 22 and a limit inclined surface 23, the main mounting surface 21 is fixedly connected with the vehicle frame 7 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com