A method for deformation and heightening of crawler chassis

A crawler chassis and crawler technology, which is applied to tracked vehicles, motor vehicles, transportation and packaging, etc., can solve problems such as harsh environment, poor performance, and inability to deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] A deformation and heightening method of a crawler chassis, the steps of which are:

[0064] (1) During normal travel;

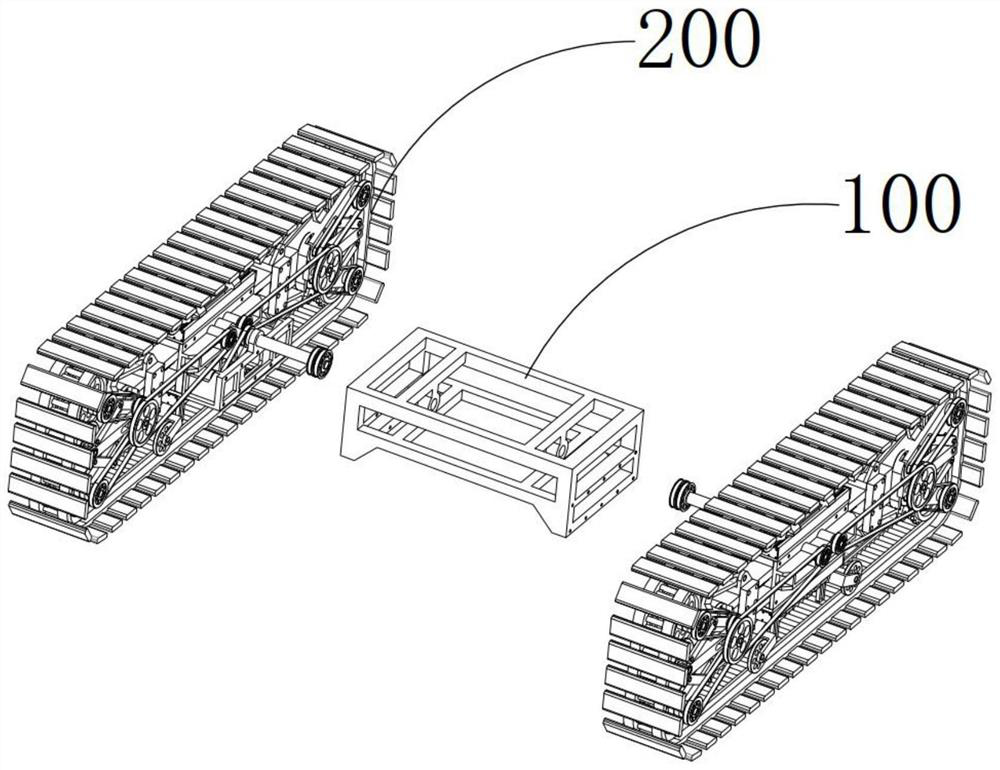

[0065] S1: In the initial state, the crawler belt 210 is quadrangular and the ground clearance of the chassis frame 100 is small. At this time, the traveling drive mechanism 310 transmits power to the driving wheel 206 and drives the driving wheel 206 to rotate. The crawler wheel 200 will be suitable for carrying the machine Travel on flat outdoor ground as a whole;

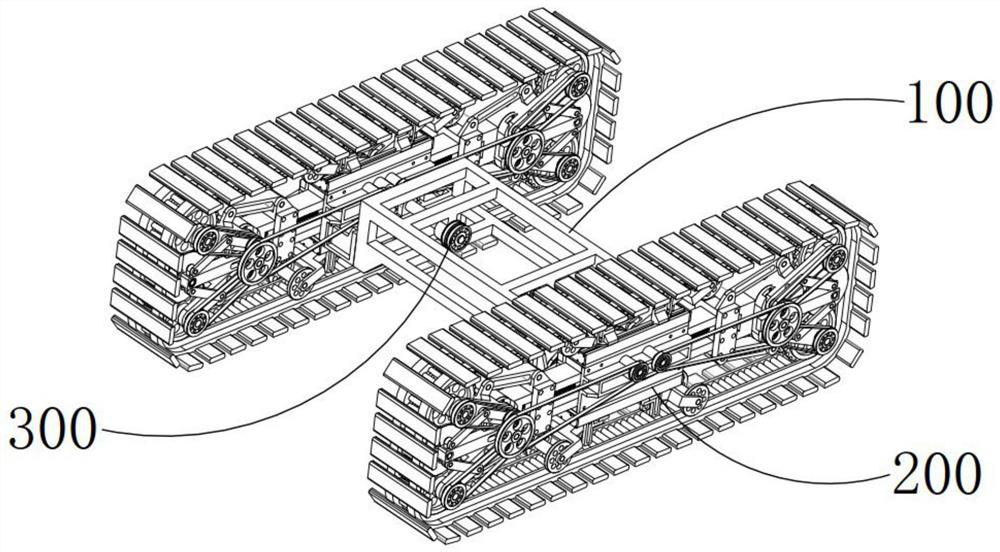

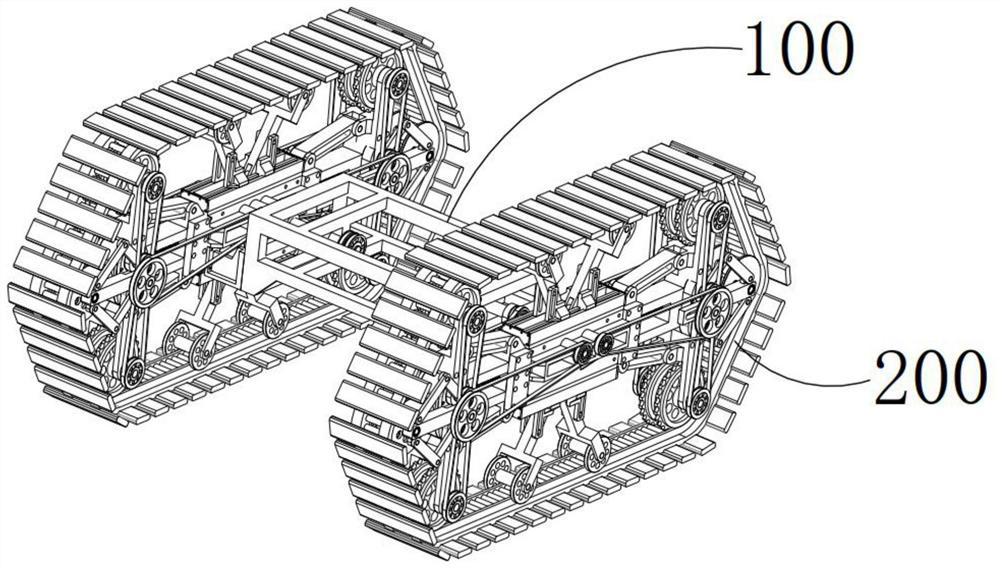

[0066] The track wheel 200 includes a left track wheel and a right track wheel arranged symmetrically. The left track wheel is fixedly connected to one end of the chassis frame 100, and the right track wheel is fixedly connected to the other end of the chassis frame 100. wheel combination, the tensioning mechanism 220 symmetrically arranged front and back, the supporting mechanism 230 arranged symmetrically up and down, and the crawler belt 210 wound on the driving wheel 206, the tension...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com