LED spotlight

A technology of LED spotlights and LED light sources, applied in the field of lighting, can solve the problems of high cost, complex structure, low efficiency, etc., and achieve the effect of low cost, good effect and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

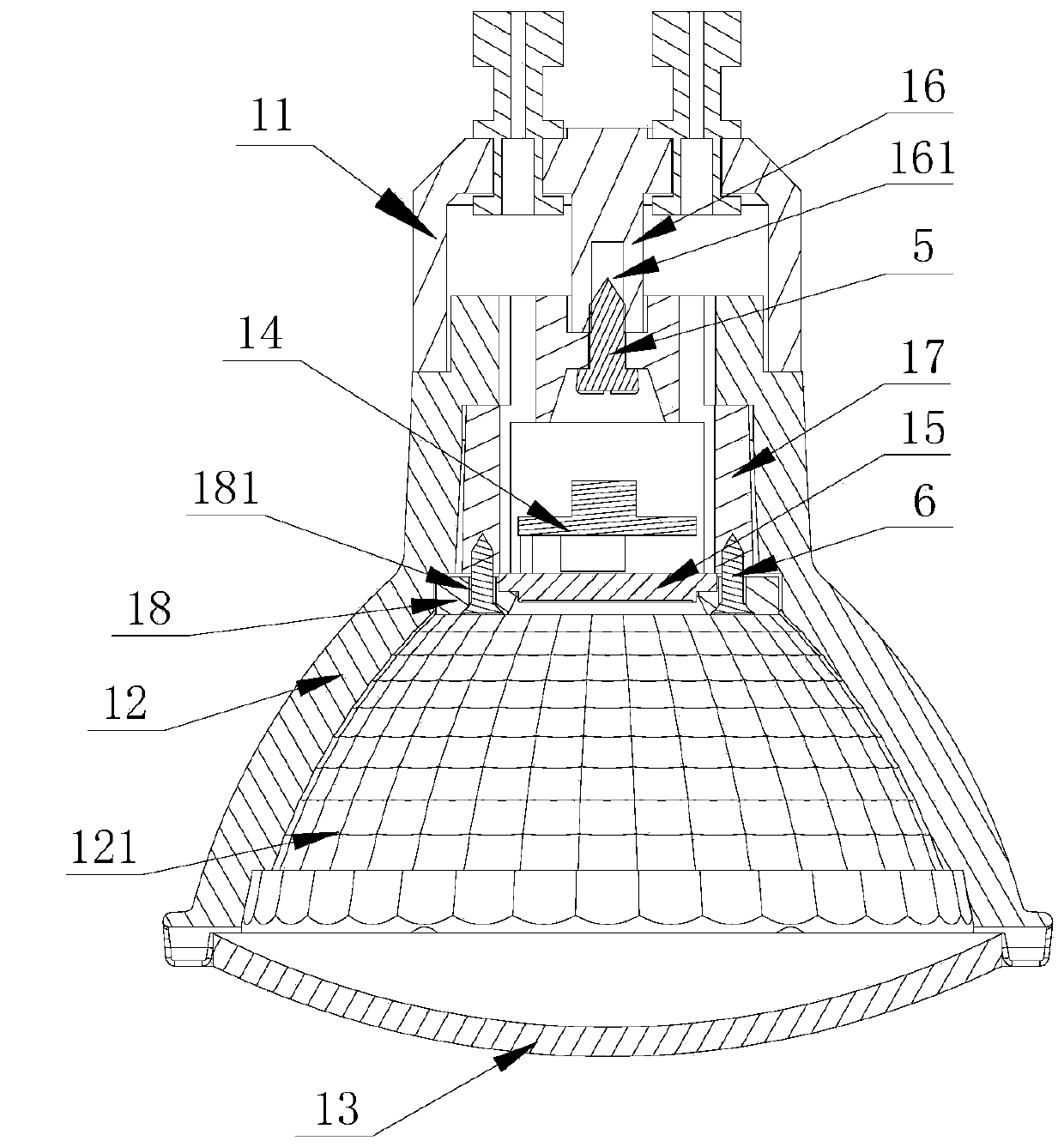

[0030] Such as Image 6 , Figure 7 Shown is a schematic structural diagram of another LED spotlight of the present invention. In this embodiment, the structure of the connector is different from that of Embodiment 1. An LED spotlight in this embodiment includes a lamp cap 21, a glass lamp cup body 22, and a lamp cover 23. A power supply 24 and an LED light source 25 are arranged in the glass lamp cup body. slot 221, the edge of the installation port is provided with a lower ventilation slot 222, the bottom of the lamp cap 21 is provided with a connector, the connector includes a base 26 arranged inside the lamp cap and a connecting rod 27 and two connecting rods arranged at the bottom of the base 26 A buckle 28, the side wall of the base 26 is provided with an external thread 261, the connecting rod 27 is arranged at the center of the inner surface of the lamp cap, and is integrally formed with the lamp cap, and the buckle 28 is arranged on both sides of the connecting rod. ...

Embodiment 3

[0032] Such as Figure 8 As shown, it is a schematic structural diagram of an LED spotlight according to Embodiment 3 of the present invention, which includes a lamp cap 31, a glass lamp cup body 32 and a lamp cover 33, and an upper ventilation slot 321 is provided on the edge of the lamp opening of the glass lamp cup body. The edge of the installation opening is provided with a lower ventilation slot 322 . However, in the present invention, except that the structure of the lamp cap 31 and the glass lamp cup body 32 are different from those of the lamp cap 21 and the glass lamp cup body 22 in the second embodiment, the others are the same as those in the second embodiment, and will not be repeated here.

Embodiment 4

[0034] In the present invention, the lamp holder is not limited to the above-mentioned structural form, and can also be as Figure 9 shown.

[0035] In the present invention, it is also possible to set the upper ventilation slot at the lamp opening of the glass lamp cup body alone, or to set the lower ventilation slot at the installation port of the glass lamp cup body alone, and the number of the upper ventilation slots and the lower ventilation slots can be adjusted according to the needs. to set.

[0036] In the present invention, besides glass, the lamp cup body can also be made of plastic, metal or ceramics.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com