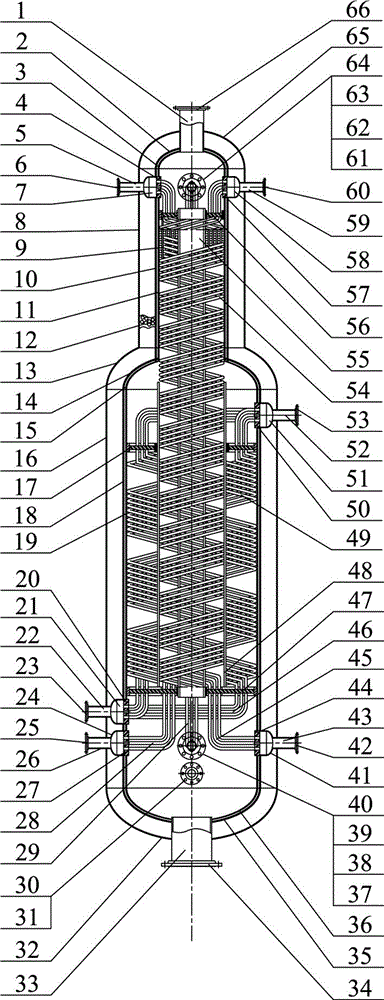

Two-stage back heating multi-strand winding pipe type heat exchange device for low-temperature liquid nitrogen

A coiled-tube, low-temperature liquid nitrogen technology, applied in heat exchanger types, indirect heat exchangers, lighting and heating equipment, etc. Discontinuation and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Processing and manufacturing low-temperature liquid nitrogen with two-stage regenerative multi-stream winding tube heat exchange equipment, including two-stage high-pressure N 2 Inlet connector (1), secondary upper head multi-layer vacuum insulation layer (2), secondary internal pressure upper head (3), secondary nitrogen outlet tube plate (4), secondary nitrogen outlet connector (5) ), secondary nitrogen outlet flange (6), secondary nitrogen outlet pipe box (7), secondary external pressure upper cylinder (8), secondary partition (9), secondary upper cylinder multilayer Vacuum insulation layer (10), secondary internal pressure upper cylinder (11), secondary pearl sand (12), secondary external pressure head (13), secondary internal pressure head and multilayer vacuum insulation layer (14) , Secondary internal pressure head (15), secondary external pressure lower cylinder (16), secondary support ring (17), secondary lower cylinder multilayer vacuum insulation layer (18), se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com