Multi-strand winding pipe type main back heating and heat exchange device for low-temperature liquid nitrogen

A low-temperature liquid nitrogen, winding tube technology, applied in lighting and heating equipment, liquefaction, refrigeration and liquefaction, etc., can solve the problems of reducing reflux temperature, poor self-shrinking ability, and large number of heat exchangers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

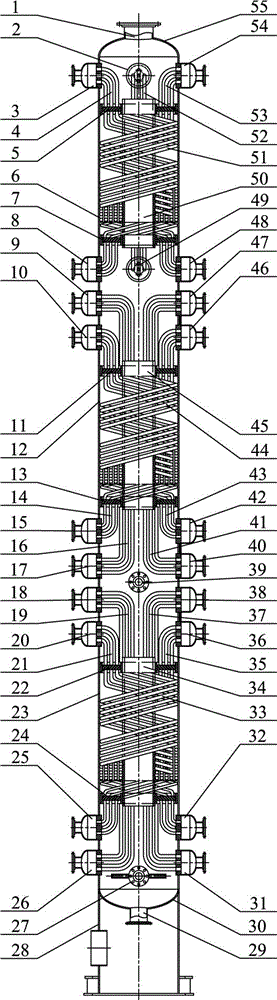

[0018] Processing and manufacturing multi-stream winding tube main heat exchange equipment for cryogenic liquid nitrogen, including primary nitrogen inlet (1), primary synthesis gas outlet (2), primary contaminated nitrogen outlet (3), primary contaminated nitrogen winding tube bundle (4), first-level upper support ring (5), first-level cylinder body (6), first-level lower support ring (7), first-level nitrogen pollution inlet (8), second-level nitrogen pollution outlet (9), second-level Purified gas inlet (10), secondary upper support ring (11), secondary cylinder body (12), secondary lower support ring (13), secondary purified gas winding tube bundle (14), secondary purified gas outlet (15 ), the secondary nitrogen pollution winding tube bundle (16), the secondary pollution nitrogen inlet (17), the tertiary nitrogen pollution outlet (18), the tertiary nitrogen pollution winding tube bundle (19), the tertiary purified gas inlet (20), the three The first-stage purified gas win...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com