Helicopter tail rotor booster fatigue test system

A technology of helicopter tail rotor and testing system, which is applied in the testing of machine/structural components, testing of mechanical components, instruments, etc., and can solve problems such as inability to simulate hydraulic pressure of actuators and lack of testing systems for helicopter tail rotor boosters , to achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

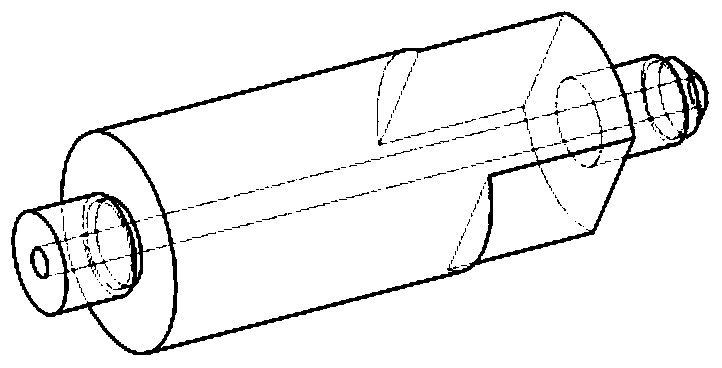

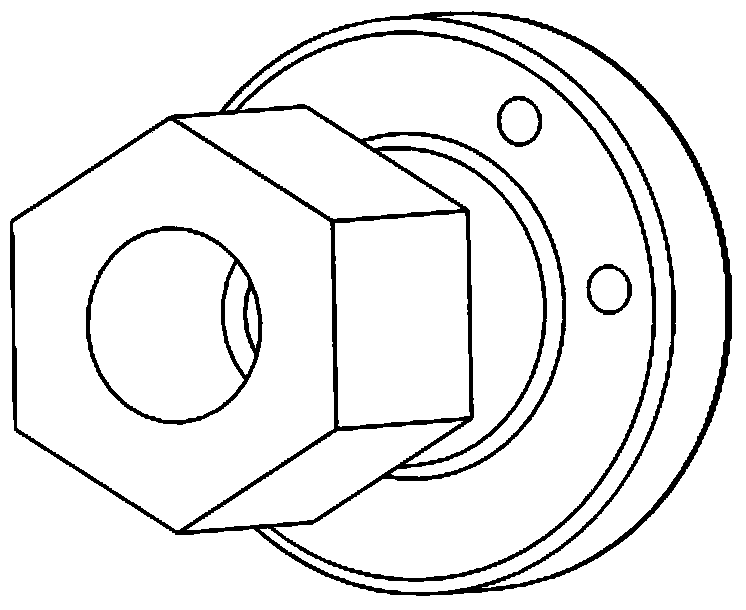

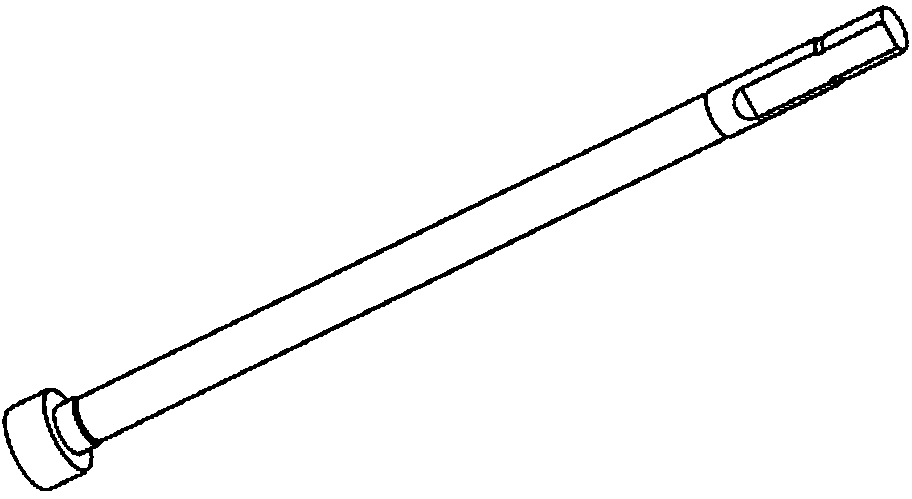

[0024] Specific implementation mode one: combine Figure 1 to Figure 5 Specific embodiments of the present invention will be described.

[0025] exist Figure 5 Among them, a helicopter tail rotor booster fatigue test testing system of the present invention consists of a fatigue testing machine 1, a hydraulic station 6, a rotary direct drive valve 4, an actuator tester 8, a digital storage oscilloscope 7, an adapter 5, an upper, The lower clamps 2, 9 and the helicopter tail rotor booster 3 are composed. The position connection relationship between them is as follows: the upper and lower clamps 2 and 9 are installed on the fatigue testing machine 1, the two ends of the helicopter tail rotor booster 3 are installed on the upper and lower clamps 2 and 9, the hydraulic station 6 is connected to the rotating The direct drive valve 4 is connected, the rotary direct drive valve 4 is connected with the helicopter tail rotor booster 3, the actuator tester 8 is connected with the rota...

specific Embodiment approach 2

[0028] Specific embodiment two: the difference between this embodiment and specific embodiment one is the selection of fatigue testing machine 1, which can be conventional fatigue testing machines such as MTS and INSTRON or self-made fatigue testing machines, helicopter tail rotor booster fatigue testing testing system Other design ideas and connection methods are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com