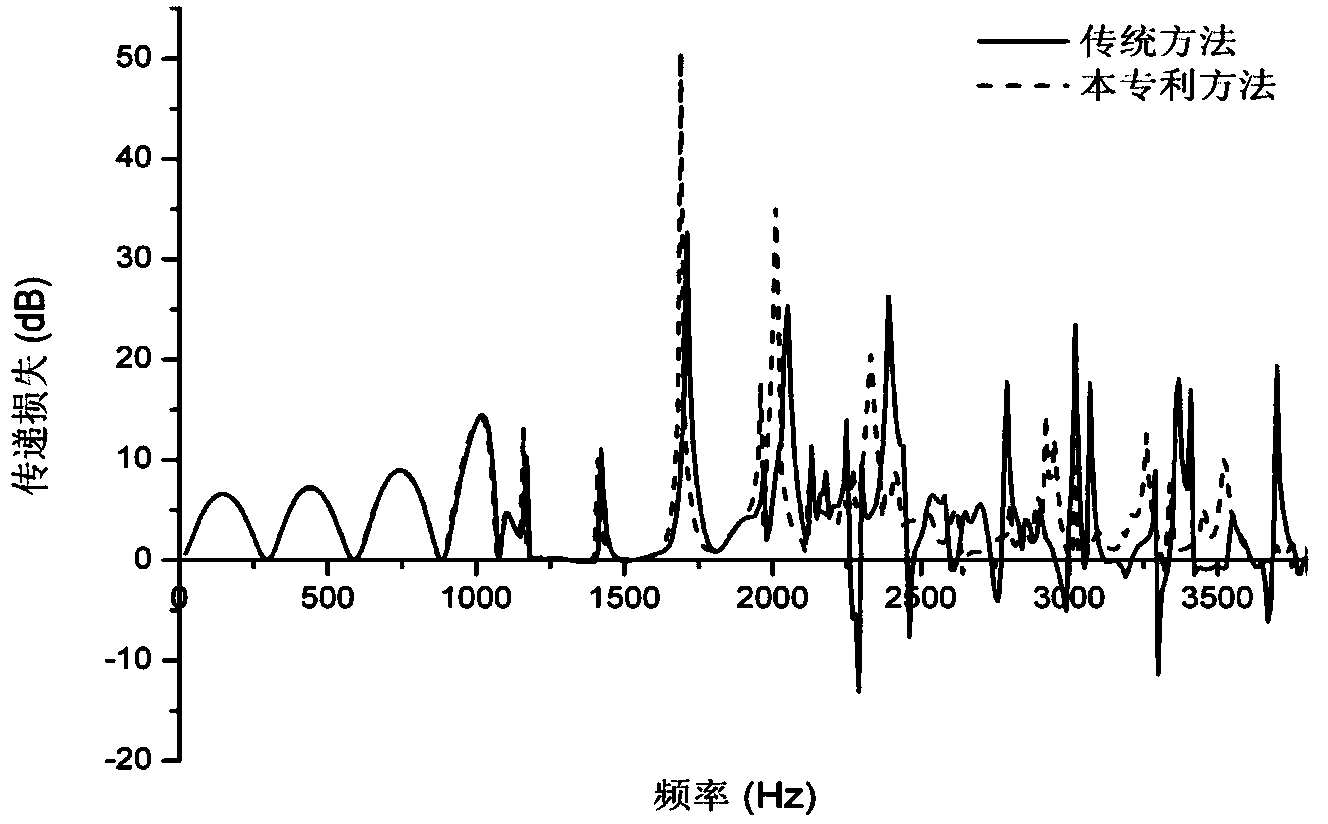

Experimental measurement method for medium-high frequency acoustic performance of large-pipe-diameter silencer

A technology of acoustic performance, measurement method, applied in the field of measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

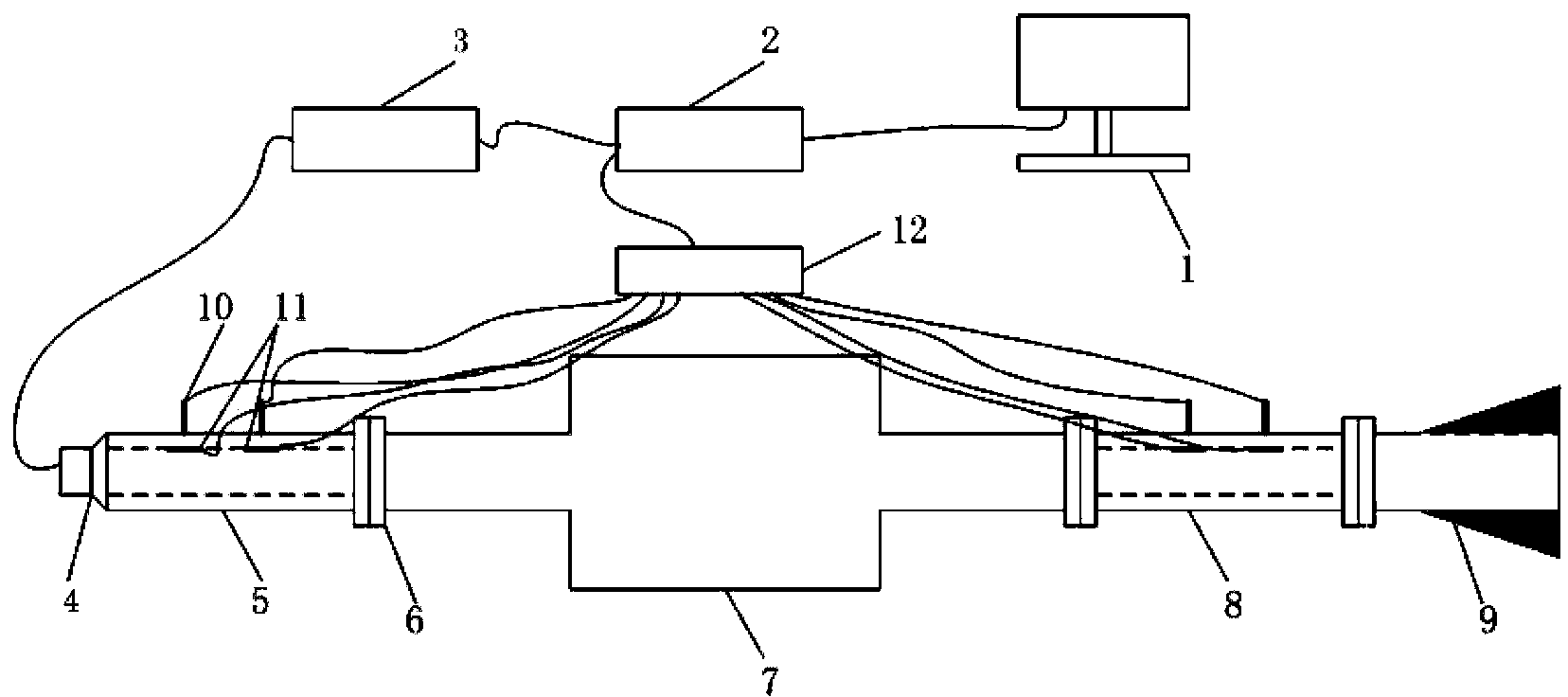

[0029] The present invention is described in more detail below in conjunction with accompanying drawing example:

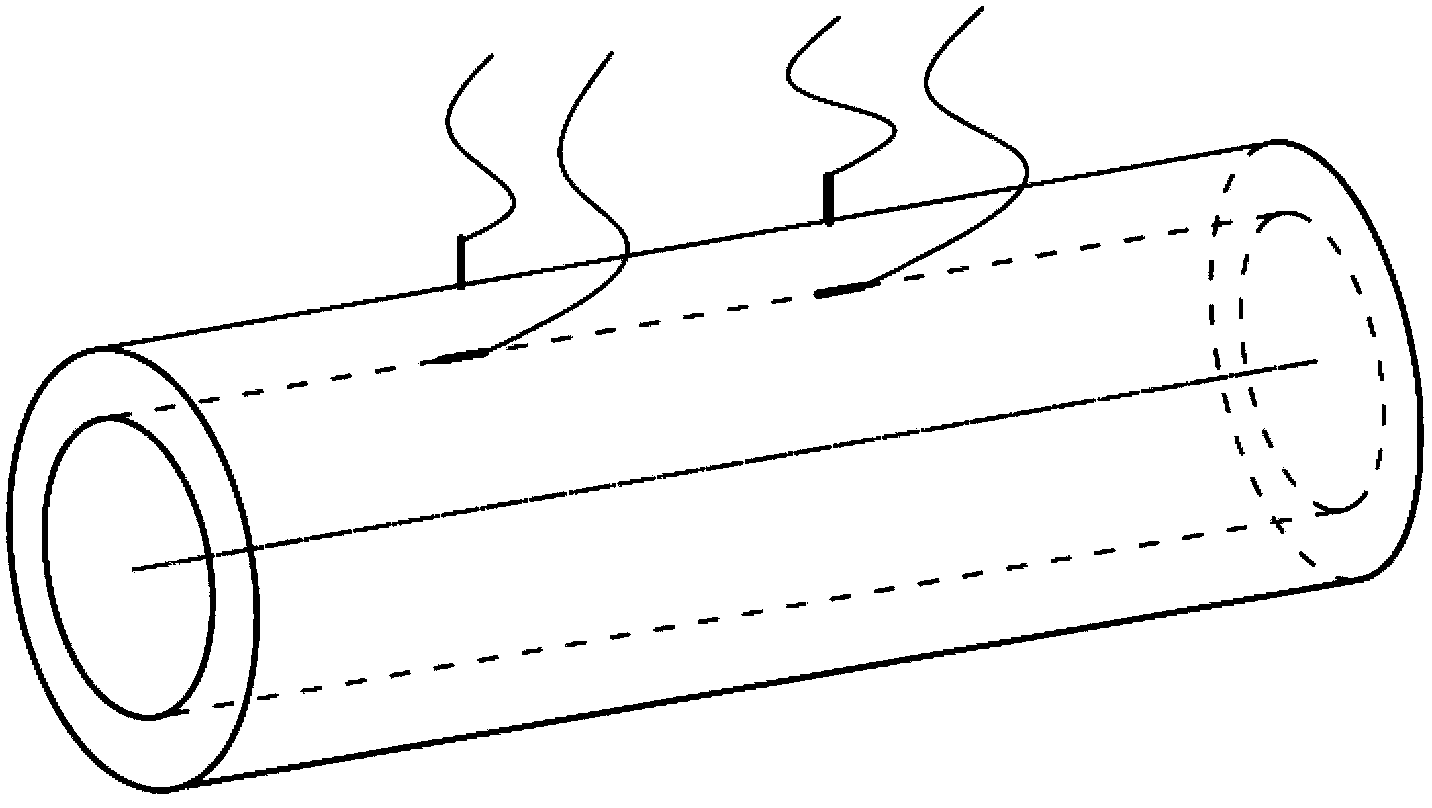

[0030] to combine Figure 1~4 , the experimental device of the present invention comprises computer 1, the multi-channel data acquisition analyzer 2 that links to each other with computer, power amplifier 3, loudspeaker 4, what is connected with loudspeaker is inlet measuring pipe section 5, and inlet measuring pipe section passes flange 6 and muffler to be tested 7, the muffler to be tested is connected to the outlet measuring pipe section 8 through a flange, and the outlet measuring pipe section is connected to the end muffler 9 through a flange, wherein a gasket is provided at the flange connection to prevent sound leakage. The piezoelectric microphone 10 and the piezoresistive microphone 11 are connected to a charge amplifier 12 . Placed at the front of the test setup is a 250W speaker. Connected with the loudspeaker is the inlet tube measuring tube section,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com