Device for achieving temperature lowering of electric soldering iron through touch switch

A technology of touching a switch and an electric soldering iron, which is applied in the direction of using electric means for temperature control, etc., can solve the problems of easy oxidation of the soldering iron tip, waste of energy, and short time, and achieve the effect of solving the waste of energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

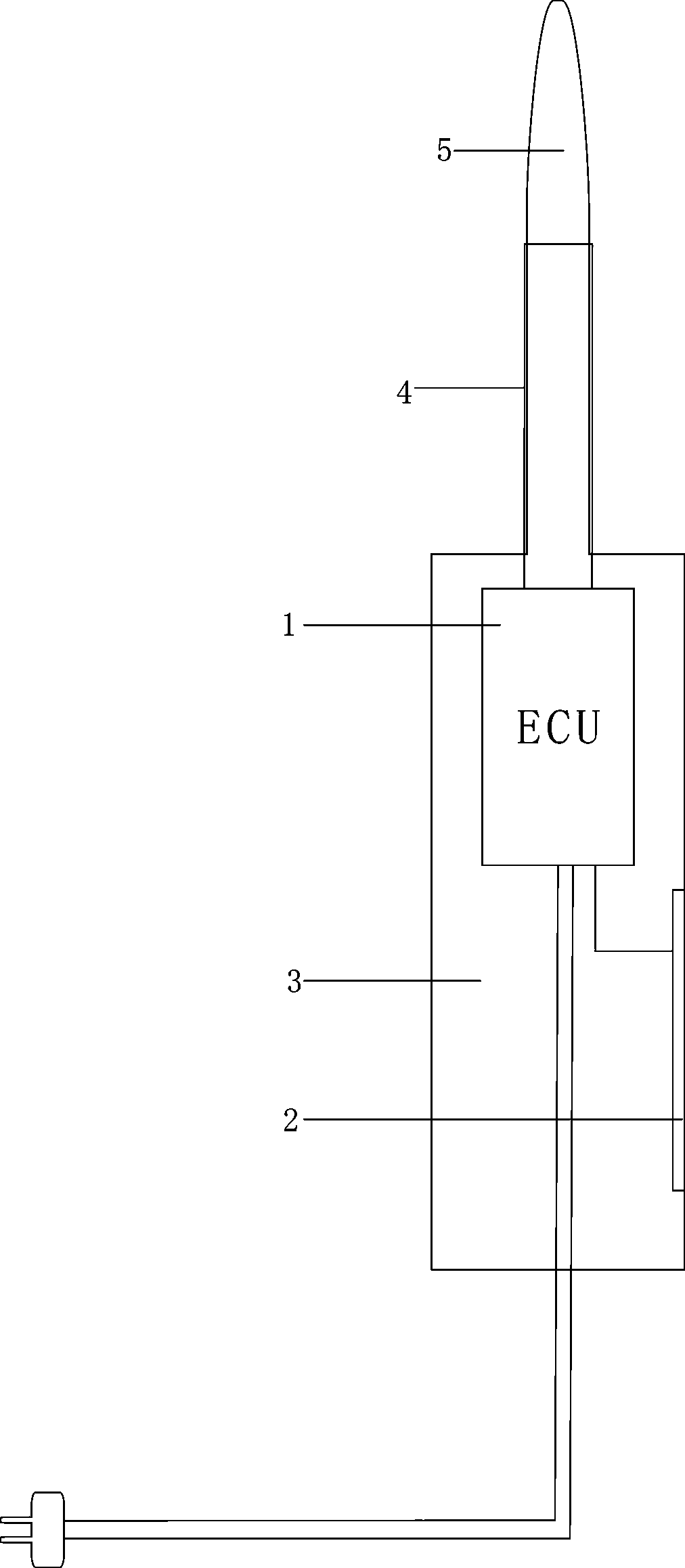

[0013] figure 1 It is a structural schematic diagram of a temperature drop device for an electric soldering iron realized by a touch switch of the present invention. The present invention consists of: a control module 1 , an inductor 2 , a main body 3 , a heating device 4 , and a heating core 5 . exist figure 1 Among them, the signal input terminal of the control module 1 is connected with the sensor 2 , and the output terminal of the control module 1 is connected with the heating device 4 .

[0014] A power line is drawn from the input end of the control module 1 .

[0015] The heating core 5 is inserted inside the heating device 4 .

[0016] The control module 1 is installed inside the main body 3 .

[0017] The inductor 2 is installed on the side of the main body 3 , and the outer surface of the inductor 2 is balanced with the outer surface of the main body 3 .

[0018] The power of the heating device 4 is 20W~200W.

[0019] The heating device 4 is divided into an exte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com