Cutting fluid filtering device having filter washing function

一种过滤装置、切削液的技术,应用在固定式滤芯过滤器、过滤分离、制造工具等方向,能够解决不能自动变更逆洗的时间、未考虑调整间隔(时间等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

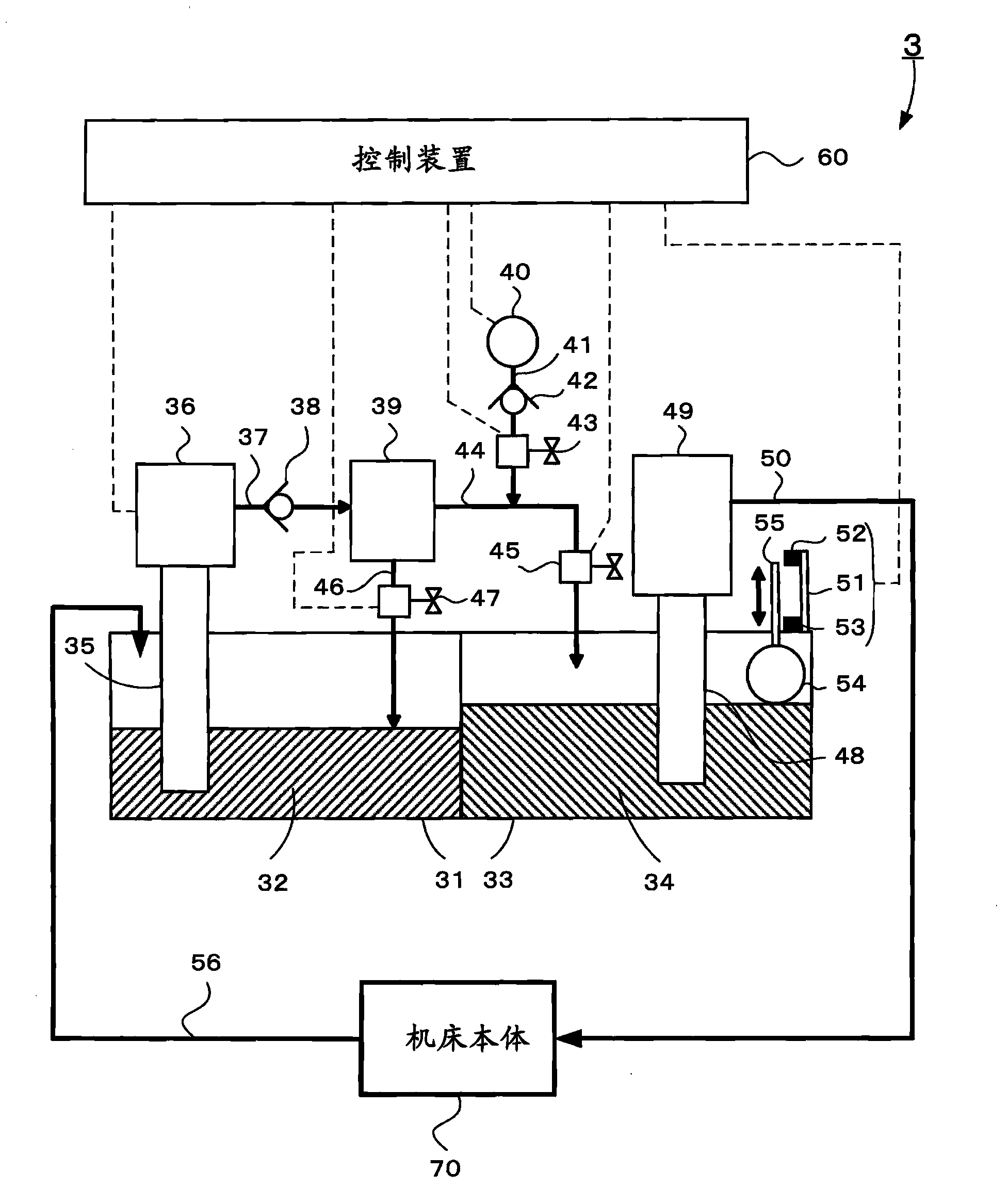

[0034] use figure 1 One embodiment of the cutting fluid filter device of the present invention will be described.

[0035] Symbol 3 is a cutting fluid filter device, symbol 31 is a dirty tank, symbol 32 is a cutting fluid containing chips, symbol 33 is a clean tank, symbol 34 is a purified cutting fluid, symbol 35 is a pipeline, and symbol 36 is a filter pump , symbol 37 is a pipeline, symbol 38 is a one-way valve, symbol 39 is a filter container with a filter (not shown) installed inside to remove impurities from the cutting fluid containing impurities, symbol 40 is an air source, and symbol 41 is a pipeline, symbol 42 is a one-way valve, symbol 43 is an air supply valve, symbol 44 is a pipeline, symbol 45 is an outflow side valve, symbol 46 is a pipeline, symbol 47 is a discharge valve, symbol 48 is a pipeline, symbol 49 is a pump, 50 is a pipe, 51 is a sensor supporting member, 52 is a proximity sensor for upper limit detection, 53 is a proximity sensor for lower limit de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com