Energy-saving air cooling spray evaporation type condenser system with overhaul washing chamber

A spray evaporation and condenser technology, applied in the field of energy-saving air-cooled spray evaporation condenser system, can solve the problems of not meeting the use requirements, increasing operating costs, system temperature, low pressure, etc., to achieve large-scale popularization and use, structure Simple and reliable, the effect of automatic temperature adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

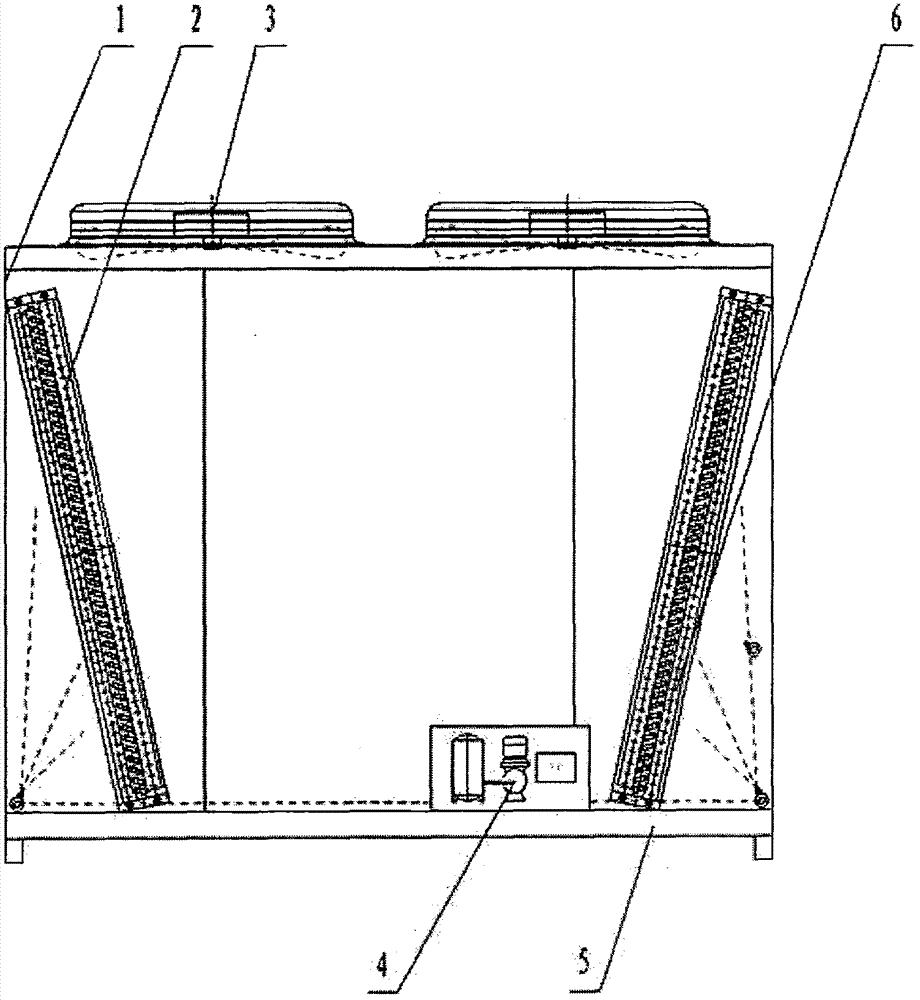

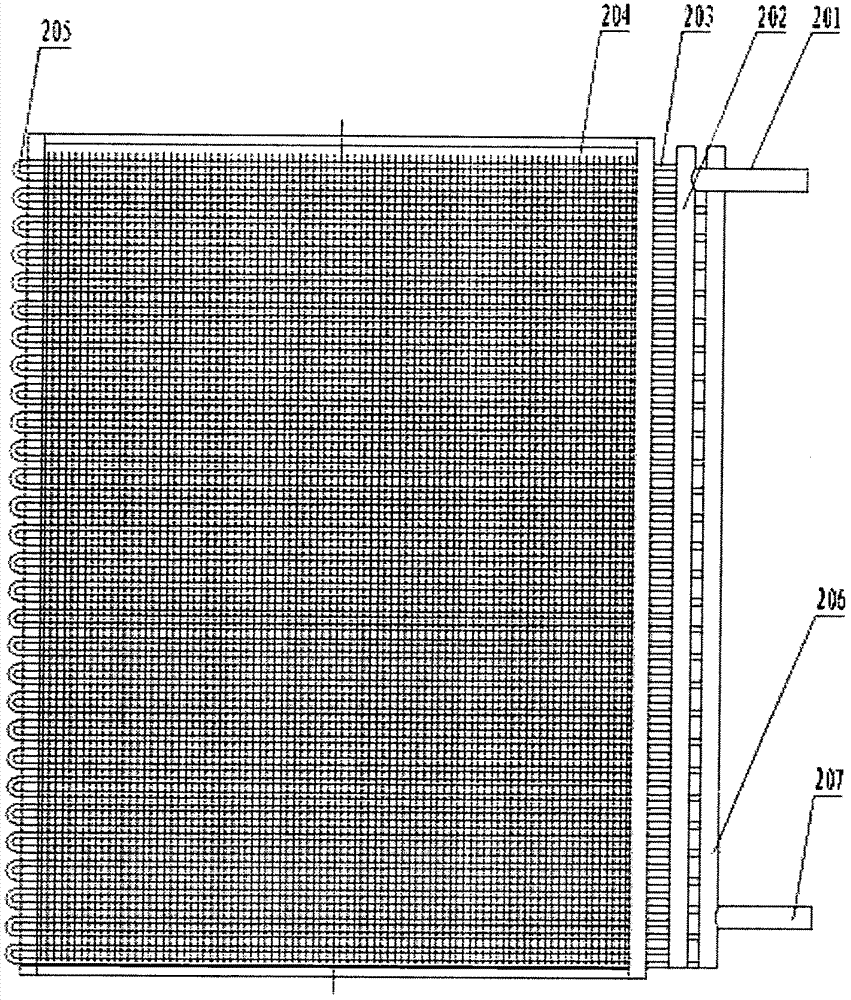

[0012] Such as Figure 1-Figure 3 As shown, an energy-saving air-cooled spray evaporative condenser system with a maintenance and cleaning room of the present invention includes a frame on which an air duct plate 1, a heat exchanger 2, an axial flow air 3, a cleaning Atomization device4. The heat exchanger 2 is composed of an air intake pipe 201, an air intake manifold 202, a copper pipe 203, a high-efficiency aluminum alloy cooling fin 204, a copper elbow 205, a liquid outlet manifold 206, and a liquid outlet pipe 207 connected together in sequence .

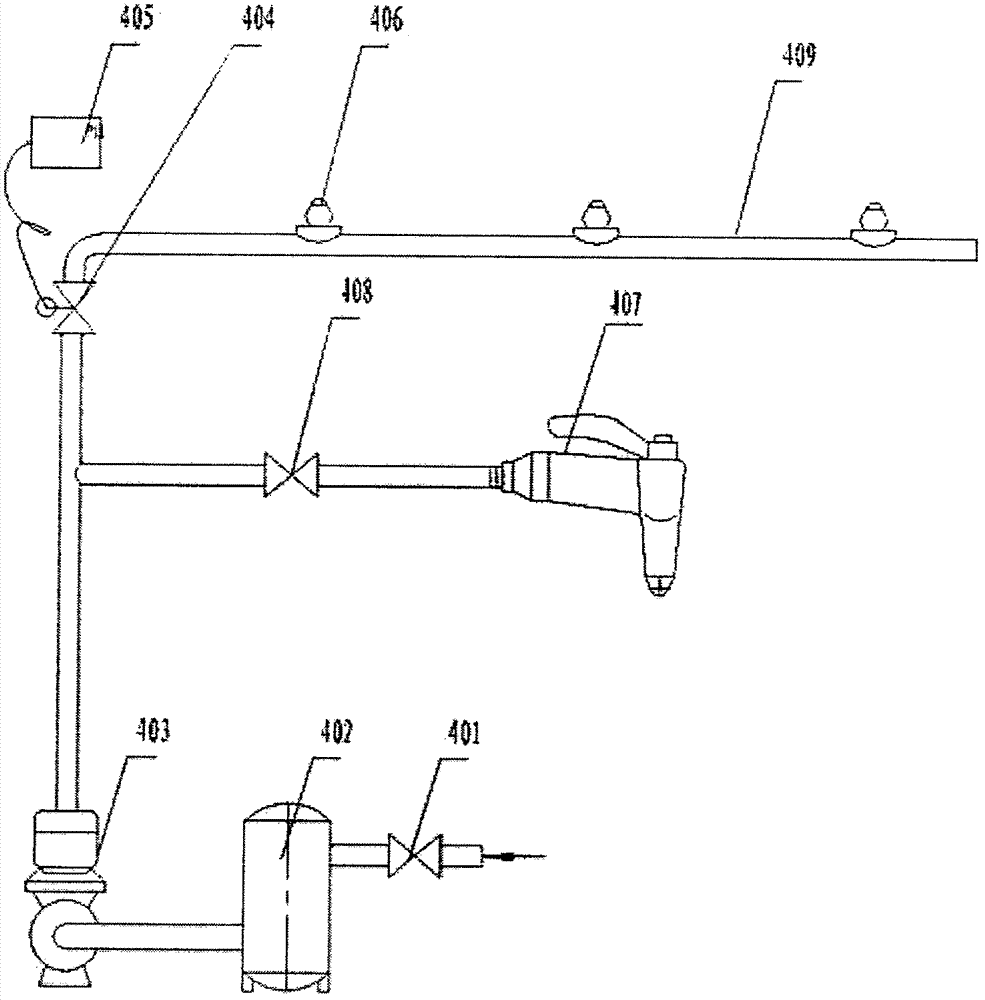

[0013] The cleaning and atomizing device 4 includes a water inlet valve 401 , a buffer water tank 402 , a water pump 403 , an electric water valve 404 , a PLC module 405 , an atomizing nozzle 406 , a cleaning water gun 407 , and a manual water valve 408 connected in sequence through a pipeline 409 .

[0014] The working principle of heat exchanger 2: high-temperature and high-pressure refrigerant gas enters from the intake pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com