Clutches used in fuel-efficient racing cars

A competitive racing car and clutch technology, which is applied to the racing field of energy-saving competitive competitions, can solve the problem that the volume and structure of the clutch cannot meet the requirements of energy-saving racing cars, and achieve the effects of simple structure, reduced energy consumption, and power separation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

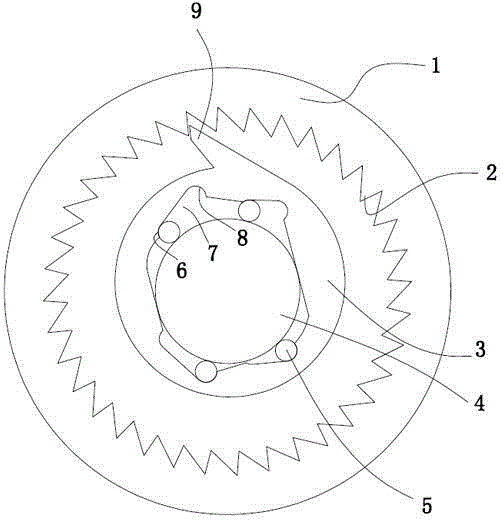

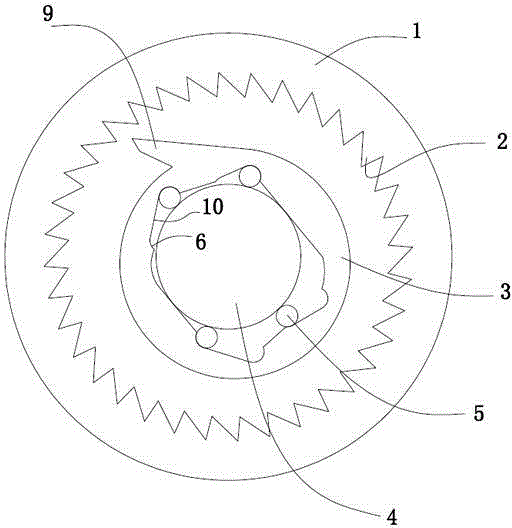

[0023] Embodiment 1: a kind of clutch that energy-saving racing car uses (referring to the attached figure 1 ), including a drive shaft 4, a drive disc 3 sleeved on the drive shaft, and a drive gear 3 outside the drive disc.

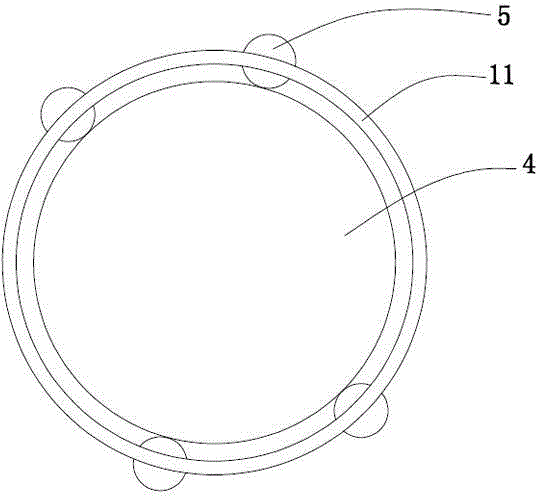

[0024] Four rollers 5 are fixedly installed by cage 11 on the outer periphery of driving shaft (see attached image 3 ), the inner ring of the driving gear is provided with internal teeth 2, and the driving disc is fixed with a transmission arm 9 that meshes with or separates from the internal teeth.

[0025] The inner wall of the drive disc is provided with an arc-shaped groove 7 at a position corresponding to the roller, and the roller and the arc-shaped groove constitute a radial movement drive mechanism for the drive disc to move radially relative to the driving shaft. The depth of the arc-shaped groove changes along the circumferential direction. The depth of the arc-shaped groove at the starting end within the range of the front 90° and rear 90° o...

Embodiment 2

[0028] Embodiment 2: A clutch used in energy-saving competitive racing cars. The outer periphery of the driving shaft is provided with an arc-shaped groove, and the inner hole wall of the driving disc is fixedly installed with rollers through a cage. The arc groove forms the start end and the end end along the rotation direction of the driving shaft, the bottom of the arc groove is a straight plane, and the depth of the start end of the arc groove within the range of the front 90° and rear 90° of the transmission arm is smaller than the end point The depth of the groove at the end, the depth of the groove at the starting end of the arc groove within the scope of another 180° on the drive disc is greater than the depth of the groove at the terminal end. A conical spring is arranged on the end surface of the arc-shaped groove where the depth of the groove is the largest, and the large diameter end of the conical spring is fixed to the end surface of the groove.

[0029] The roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com