Method for improving detection limiting sensibility of crack eddy current on surface of metal

An eddy current detection and metal surface technology is applied in the field of improving the limit sensitivity of eddy current detection of metal surface cracks, which can solve the problems of inability to distinguish noise interference signals, weak eddy current signals, and inability to detect, and achieve the effect of improving the limit sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

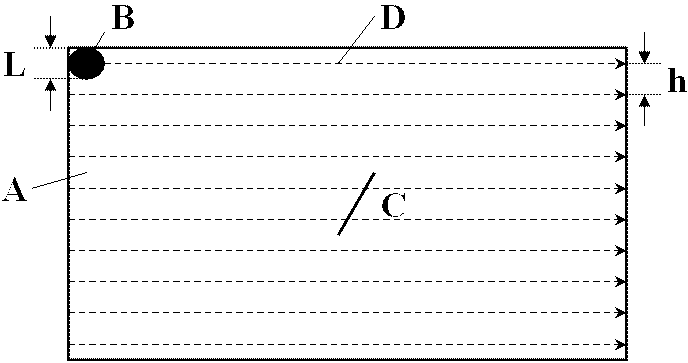

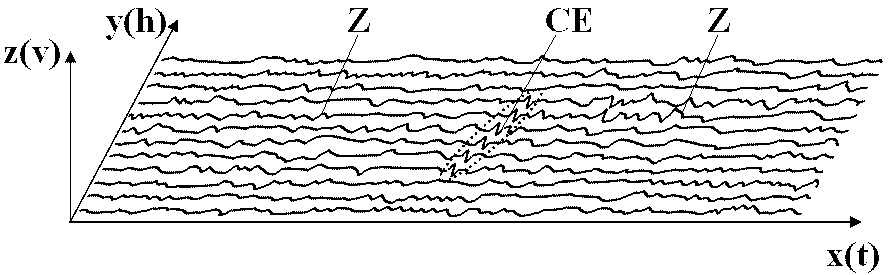

[0015] Such as figure 1 , figure 2 The embodiment shown is a method for improving the limit sensitivity of eddy current detection of metal surface cracks, which is characterized in that: based on eddy current detection, the surface crack defects of metal materials cannot be mutated, the position is constant and extends according to a certain law, and the noise interference signal changes randomly The characteristics of the detection method include the following steps,

[0016] a. Set the signal display mode of the eddy current detector to the three-dimensional time window time base memory line signal three-dimensional imaging display mode, that is, the eddy current detection time base signal is displayed and retained in the three-dimensional time window, and the x-axis of the three-dimensional time window is the signal time The x(t), y-axis is the probe translation distance x(h) perpendicular to the scanning direction, and the z-axis is the signal amplitude x(v);

[0017] b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com