A Design Method for Improving the Sensitivity of Eddy Current Detection Limit by Resonant Frequency Variation

A technology of eddy current detection and design method, which is applied in the direction of material magnetic variables, etc., can solve the problems of non-adjustable frequency, narrow bandwidth, and only suitable for fixed frequency work, etc., and achieve the effect of improving the limit sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

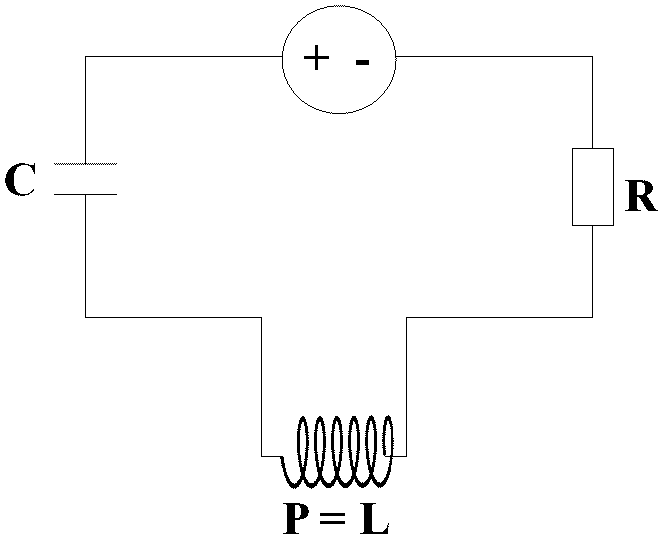

[0018] figure 1 The embodiment shown is a design method for improving the limit sensitivity of eddy current detection by changing the resonant frequency of the present invention. The frequency generated by the resonant circuit LCR is used to replace the quartz crystal oscillator in the eddy current detection instrument, and the eddy current detection coil P is used as the inductance of the resonant circuit In part L, R is the loss of the resonant loop; during the detection process, the eddy current detection coil P will change the amplitude and frequency of the defect or discontinuity of the workpiece, and further perform quadrature detection on the picked up eddy current detection signal to obtain the resonance Impedance signal plot for eddy current testing. The resonant eddy current detection impedance signal diagram contains amplitude, phase and frequency information; the resonant eddy current detection impedance signal diagram is compared with the conventional eddy current...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com