Ways to Optimize Resource Allocation

A resource allocation, resource technology, applied in the field of electric energy distribution, computer program

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

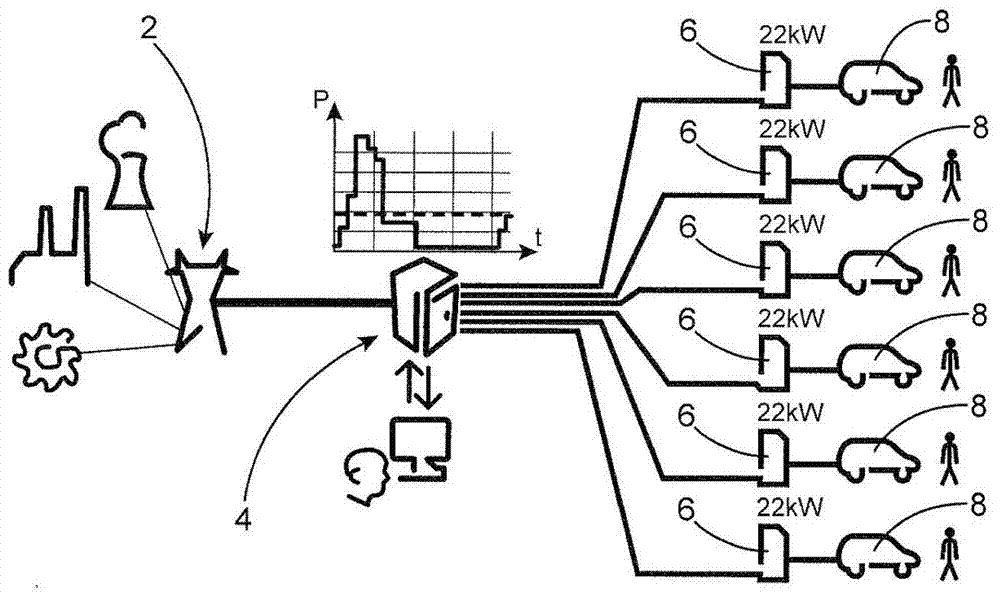

[0061] The following description is provided with reference to the accompanying drawings, figure 1 A system for providing electric energy for electric and / or hybrid vehicles is shown schematically, for example, the system includes an electric energy source 2 connected to six charging terminals 6 through a management unit 4, each charging terminal Both have a power rating of 22kW. If the operator of the system wishes to charge the vehicle 8 at full power at all times, he must obtain a contract of 6 x 22 = 132 kW. Perhaps this maximum power is reached only occasionally. The required peaks represent additional costs for the operator and may also be problematic for the power producer, who needs to invest in supplementary generation equipment to absorb temporary peaks. If the contract was awarded for a lower function level, these spikes in demand could be sufficient to shut down the installation, so that all charging terminals are unavailable.

[0062] Accordingly, it is desirab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com