Carbon material and negative electrode for nonaqueous secondary battery and nonaqueous secondary battery

A secondary battery, non-aqueous technology, applied in the direction of secondary batteries, non-aqueous electrolyte storage batteries, battery electrodes, etc., can solve the problems of unbalanced, fully satisfying the initial efficiency, etc., and achieve the effect of excellent initial capacity and excellent cycle characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

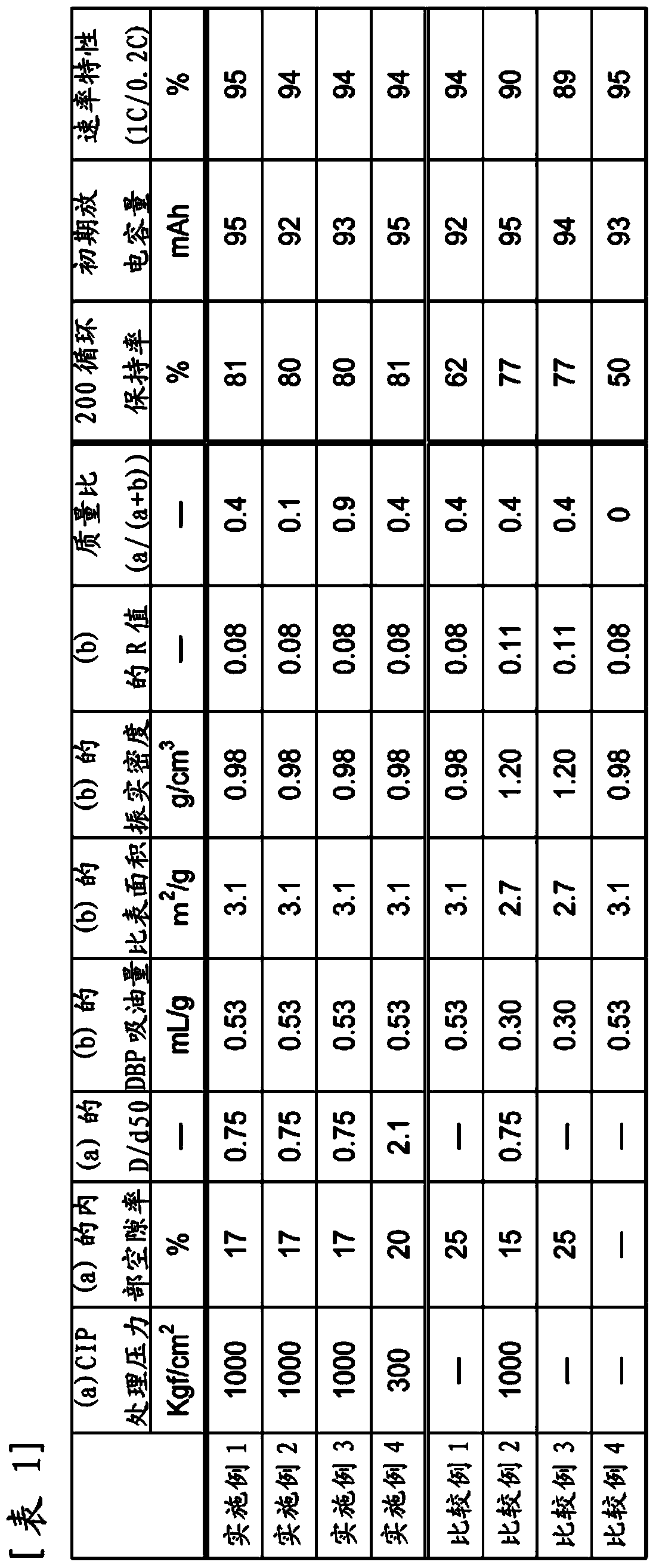

[0258] The natural graphite particles (a) and the carbonaceous material composite particles (b), that is, the graphitic material-coated graphite whose surface is roughened as carbonaceous material-coated graphite are expressed in Table 1 at the mass ratio (a) / (a+b )mix. A negative electrode was produced using the obtained carbon material, and a laminated battery was produced by the method described above, and the 200-cycle retention rate was calculated from the initial discharge capacity and the discharge capacity at the 200th cycle.

[0259] In addition, discharge rate characteristics were studied based on the ratio of the discharge capacity at a discharge rate of 1C after charging to 4.2V at 0.5C to the discharge capacity at a discharge rate of 0.2C after charging to 4.2V at 0.5C.

[0260] The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| oil absorption | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap