Mechanical differential drive mechanism

A special, electric drive technology, applied in steering mechanism, non-deflectable wheel steering, transportation and packaging, etc., can solve the problems of unsuitability for large-scale popularization and high manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

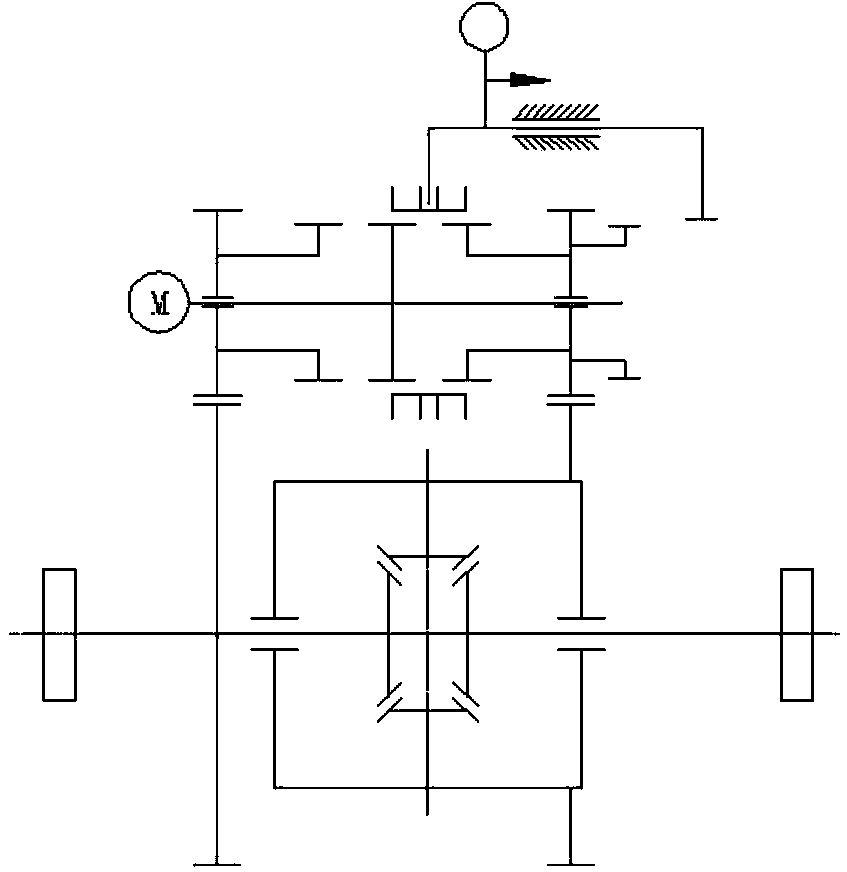

[0011] exist figure 1 , slide the joystick to the right to put the mechanism into the direct drive gear, and the meshing sleeve meshes with the direct drive drive gear. At this time, the power is from the direct drive drive gear nested on the drive shaft through the direct drive gear fixed to the differential housing. The driving driven gear is transmitted to the differential, and the differential drives the left and right half shafts to rotate at the same speed and direction, thus realizing the direct driving condition.

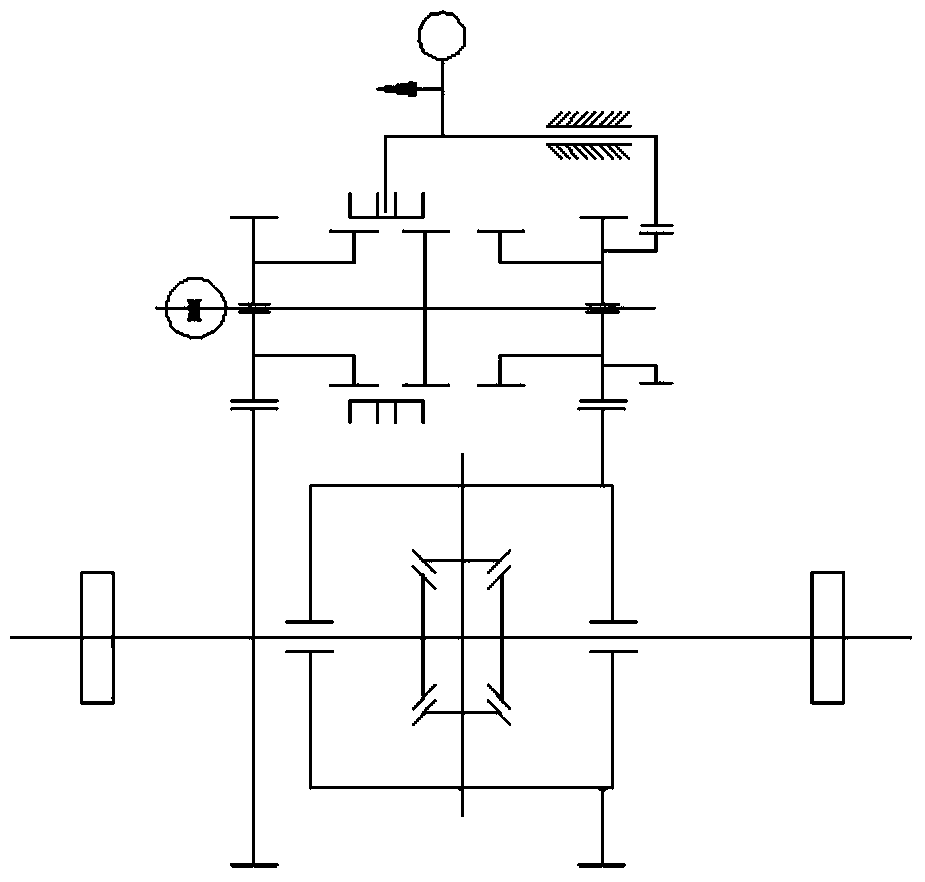

[0012] exist figure 2 , slide the joystick to the left to put the mechanism into the center steering gear, and the meshing sleeve meshes with the center steering driving gear. At this time, the power is steered from the center steering driving gear nested on the driving shaft through the center fixedly connected to the left half shaft. The driven gear is transmitted to the left half shaft; at the same time, the shift fork is engaged and locked with the dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com