Mira separation structure model for air automotive aerodynamics research

A technology of structural model and experimental research, applied in the field of automotive aerodynamics, can solve the problems of increased labor intensity and time consumption, increased test error, interference with measurement data, etc., to achieve the effect of light structure, reduced test error, and guaranteed volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

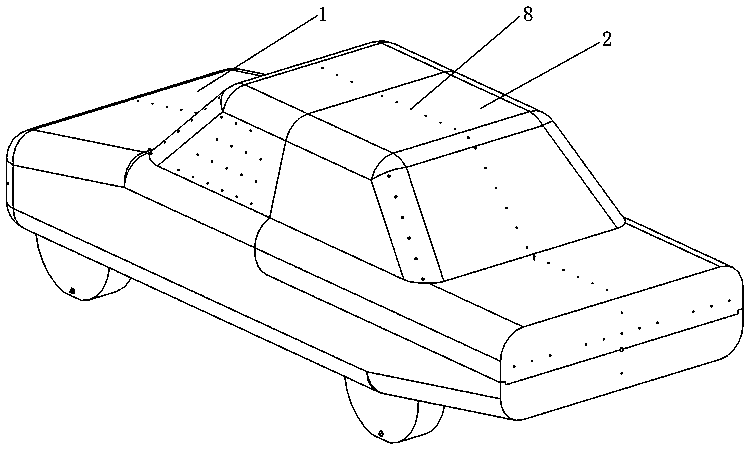

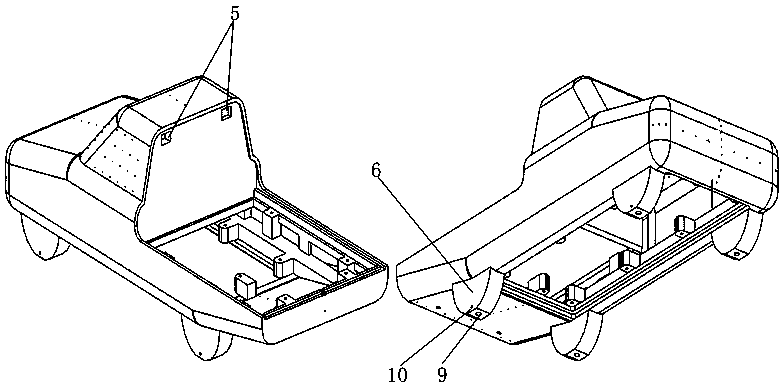

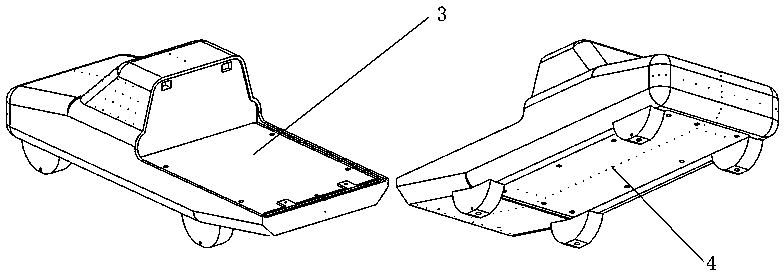

[0029] A Mira split structure model for automobile wind tunnel experimental research, including main body 1, tail cover 2, middle plate 3, and bottom plate 4; figure 2 As shown, the main body is a car body model frame, and its front half is an engine compartment and a driver's compartment, and its interior is a cavity; 4 Splicing with the main body 1 to close the cavities, the outer surfaces of the joints are all flush, and the joints between the plates have no grooves, such as image 3 Shown; The lower part of the main body of the vehicle body is symmetrically arranged with four semicircular wheels 6, the tread of the wheels 6 is provided with a vertical hole 9, and the wheel disc of the wheels 6 is provided with a threaded hole 10; the threaded hole 10 and the vertical hole 9 crosses, such as figure 2 , which is convenient for later model fixing.

[0030] Such as figure 1 , 2 , 3, 4; the tail cover 2 is placed on the middle plate 3; the tail cover 2 is in the shape of ...

Embodiment 2

[0036]The difference between this embodiment and Embodiment 1 is that, based on the mortise and tenon connection between the tail cap and the main body, and the tail cap is a shell-like structure, which is light and easy to disassemble, the Mira split structure model provided by the present invention has multiple replaceable For the installed tail caps 2 of different shapes, each tail cap can be evenly spliced on the main body and fixed. During the test, the tail cover 2 can be easily replaced to realize the replacement of the back. Compared with the traditional solid model, this model is convenient for comparative research and saves materials. It only needs one main body to cooperate with different tail covers to transform into multiple models. Model.

[0037] Such as Figure 5 , 6 As shown, tail covers 21, 22, and 23 with different inclination angles are respectively assembled on the main body 1, so that the vehicle type can be set as a sedan, a fastback hatchback, and a...

Embodiment 3

[0039] In this embodiment, a method for installing and fixing the models described in Embodiment 1 and Embodiment 2 is provided.

[0040] When testing in a wind tunnel, if the model is not installed firmly, it is very likely to cause inaccurate test results or even accidents. Therefore, the car model must be firmly installed on the balance measurement system. In this embodiment, four neatly arranged pillars (not shown in the figure) are arranged on the supporting surface of the strain balance, and at the same time, as figure 2 The vertical holes 9 are respectively provided on the treads of the four wheels 6 of the model shown, and the vertical holes can be connected with the pillars on the balance in a manner of hole shaft cooperation, that is, the pillars on the support surface of the balance are respectively inserted into the corresponding support pillars. The initial fixation of the model can be completed in the hole, but for the convenience of installation, the diameter o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com