Anti-crack device and process for bearing conical rolling body

A rolling element and anti-crack technology, which is applied in the field of bearing manufacturing, can solve the problems of unsatisfactory product quality, bearing reliability, blanking uniformity, white ash thickness, and production efficiency that cannot adapt to the operation mode. The effect of saving equipment occupancy rate and reducing scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

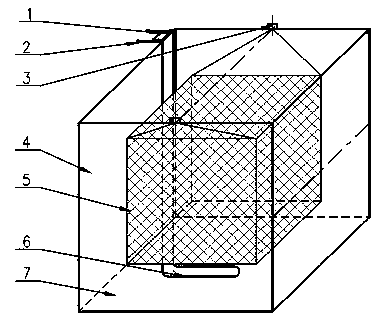

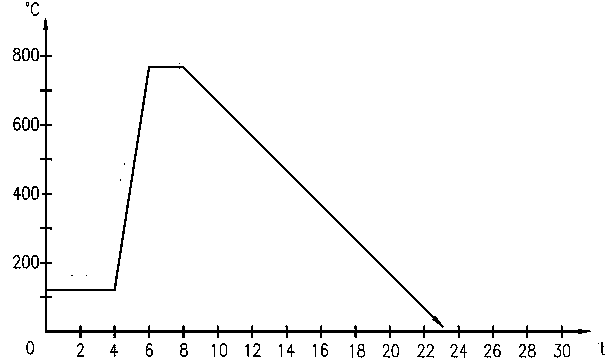

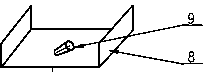

[0021] After the rolling body is pressed by the roller automatic cold heading machine, the temperature of the rolling body is 110°C, and it flows into the mesh box from the material channel. At this time, the oil is heated through the adjustment of the thermostat. When the temperature reaches 130°C, the shaker is started. Under the action of the shaker, the temperature of the rolling body and the temperature of the liquid oil are balanced. After 4 hours, until the mesh box is full, the rolling body is lifted and dried, and dried quickly to prevent high-temperature combustion during annealing, and then Transfer to heat treatment and annealing to stabilize the structure, heat for 2 hours and the temperature rises to 770°C, hold for 2.5 hours and then cool to room temperature with the furnace, so far the whole process of structure stabilization is completed, and then the post-processing work such as machining is performed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com