Concrete material taking platform and anti-collision damping device

A technology of reclaiming platform and buffer device, applied in the direction of dams, arch dams, etc., can solve the problems of deformation and damage of Bailey beams on the side of the platform, large impact load on the side of the platform, and poor impact load capacity, so as to reduce the protection area , reduce construction costs, and have a large buffer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

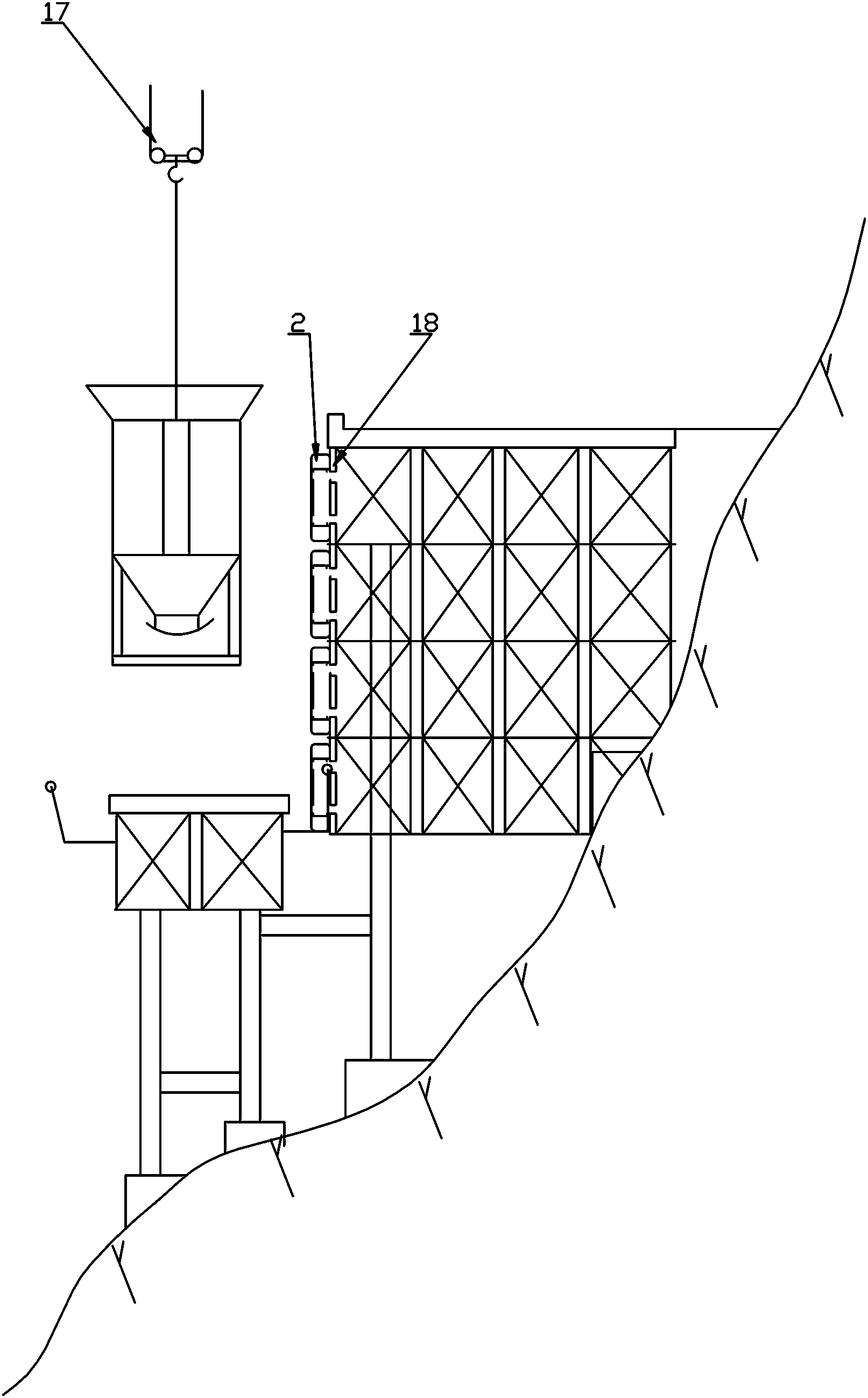

[0043] The buffer device of the present invention can also be used alone for buffering between other hoisting objects and fixed structures.

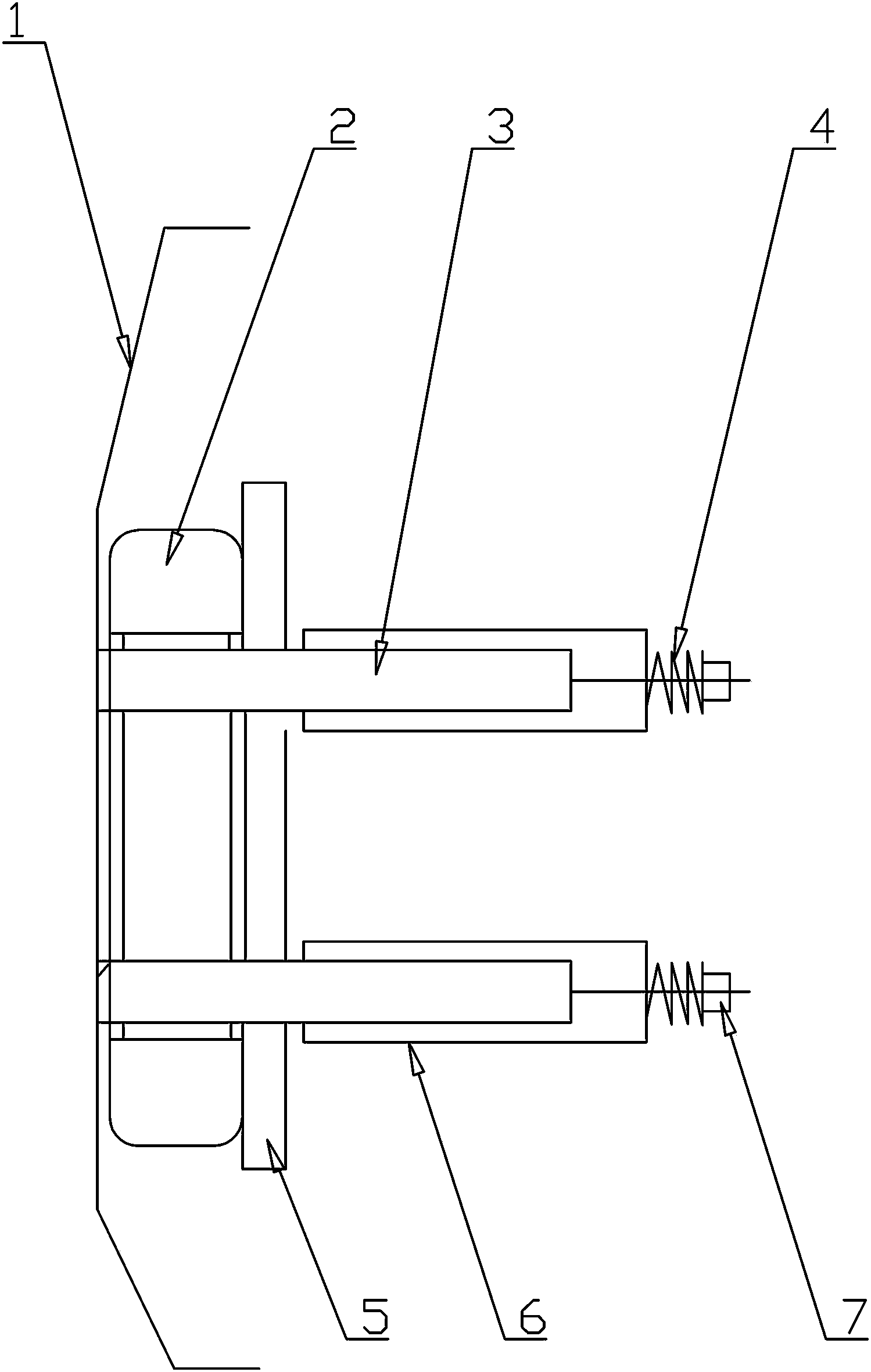

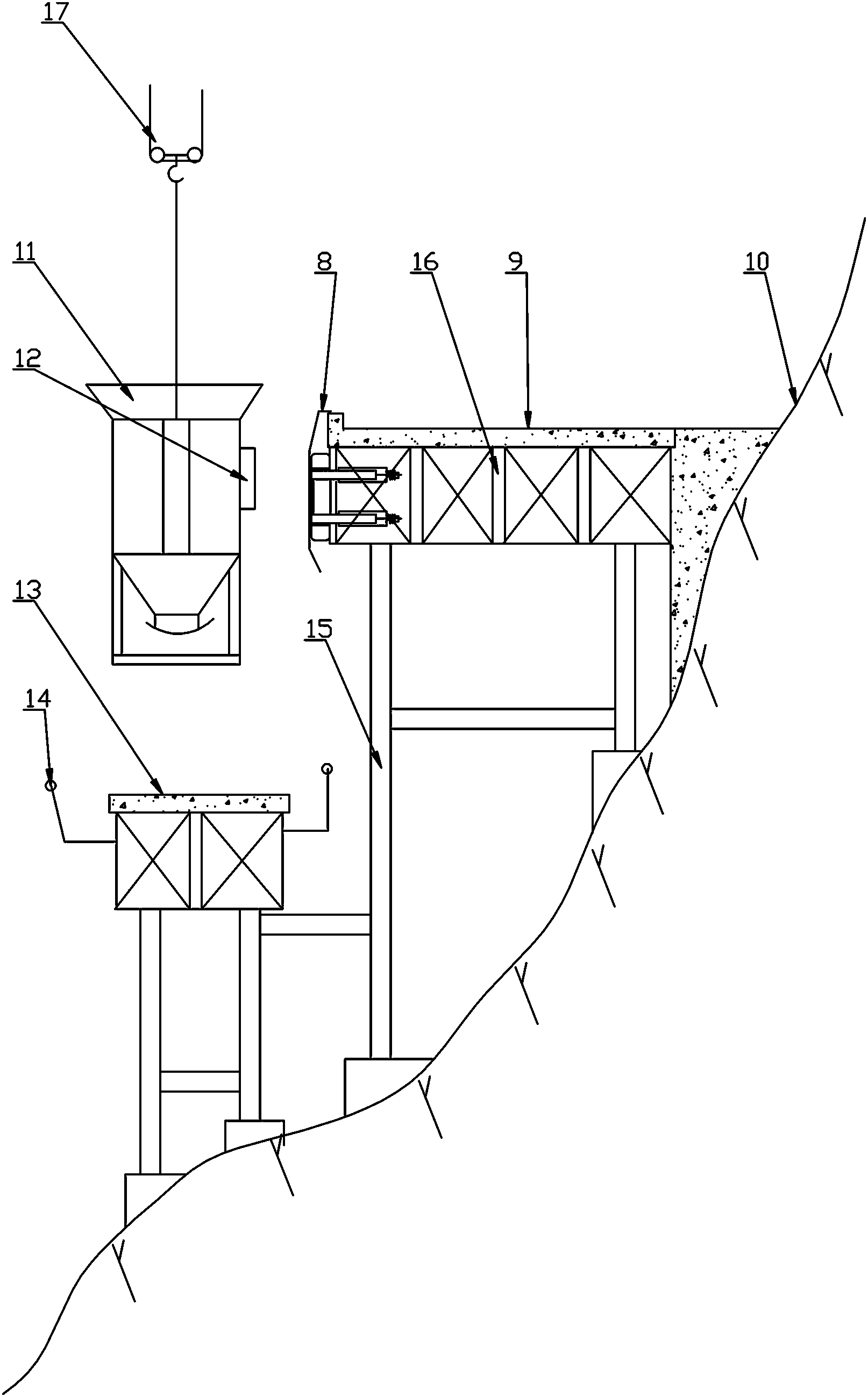

[0044] Such as figure 1 Among them, an anti-collision buffer device for a concrete reclaiming platform, the back of the panel 1 is welded to a plurality of sliding rods 3, and the ends of the sliding rods 3 are welded with screw rods;

[0045] The support frame 5 is welded to the Bailey beam 16, and a plurality of sliding sleeves 6 are also arranged on the Bailey beam 16 corresponding to the sliding rod 3;

[0046] The slide bar 3 passes through the buffer pad 2, the support frame 5, the sliding sleeve 6 and the spring 4 and is connected with the nut 7 in turn;

[0047] The upper end and the lower end of the panel 1 are provided with bent sections towards the back. The width of the panel 1 is 1-1.8 meters, the angle between the upper bending section and the extension line of the panel 1 is 10-30°, and the angle between the lower bendi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Limit | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com