Core valve energy storing type hydraulic down-the-hole hammer

A technology of down-the-hole hammer and core valve, which is used in drilling equipment, earth-moving drilling, driving device for drilling in wellbore, etc. Function loss and other problems, to achieve the effect of timely and accurate valve switching, not easy to collect sand, and small caliber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

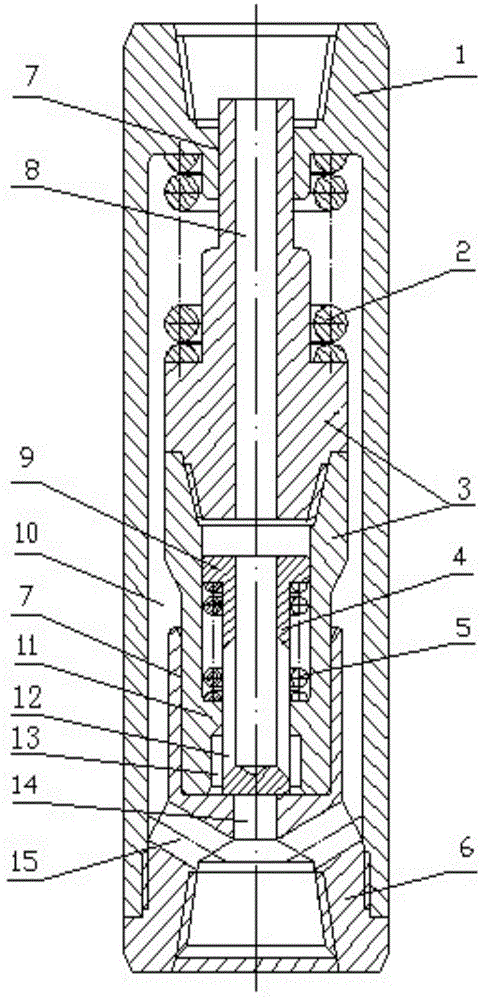

[0030] Example as figure 1 Shown: The down-the-hole hammer consists of the shell (1), hammer spring (2), hammer body (3) composed of upper hammer body and lower hammer body, core valve (4), valve spring (5), lower joint (6) Composition; between the shell (1) and the lower joint (6) and between the upper hammer body and the lower hammer body are connected by threads, the hammer spring (2) is set on the upper and middle sections of the upper hammer body, the core valve (4) and Valve spring (5) is contained in the inner chamber of lower hammer. The valve spring (5) is set outside the core valve (4), between the ring-shaped big head (9) on the top of the core valve and the step (11) in the inner cavity; the upper part of the upper hammer body and the shell are dynamically sealed (7), The lower part of the lower hammer body and the cylindrical inner wall of the upper part of the lower joint are dynamically sealed (7); the working fluid enters from the upper end of the casing (1), ...

Embodiment 2

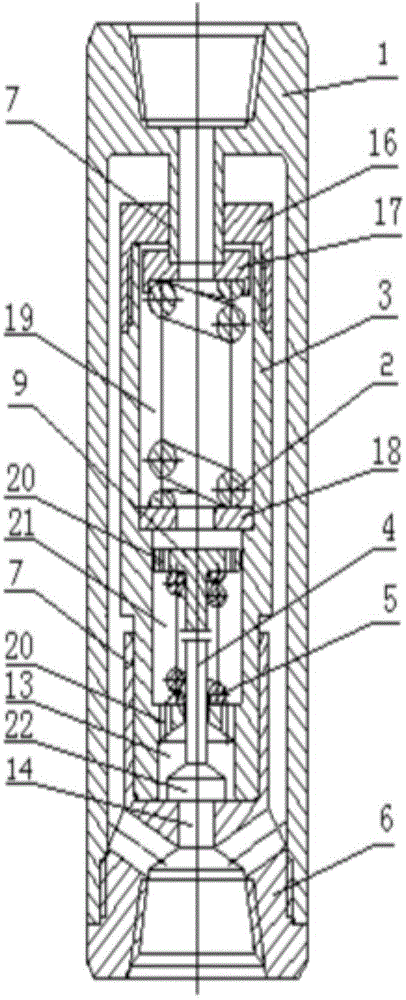

[0032] Example two such as figure 2 Shown: the down-the-hole hammer consists of a shell (1), an end cover (16), an upper spring seat (17), a hammer body (3), a hammer spring (2), a lower spring seat (18), a core valve (4), The valve spring (5) and the lower joint (6) are composed; between the shell (1) and the lower joint (6) and between the end cover (16) and the hammer body (3) are connected by threads, and the hammer spring (2) is installed In the hammer body upper cavity (19), the core valve (4) runs through the hammer body middle cavity (21) and the hammer body lower cavity (13), and the valve spring (5) is sleeved in the middle section of the core valve (4). Between the ring-shaped big head (9) on the top of the core valve and the step of the middle cavity of the hammer body (21); between the upper part of the casing (1) and the end cover (16) and between the lower section of the hammer body (3) and the lower joint ( 6) The cylindrical inner walls of the upper section ...

Embodiment 3

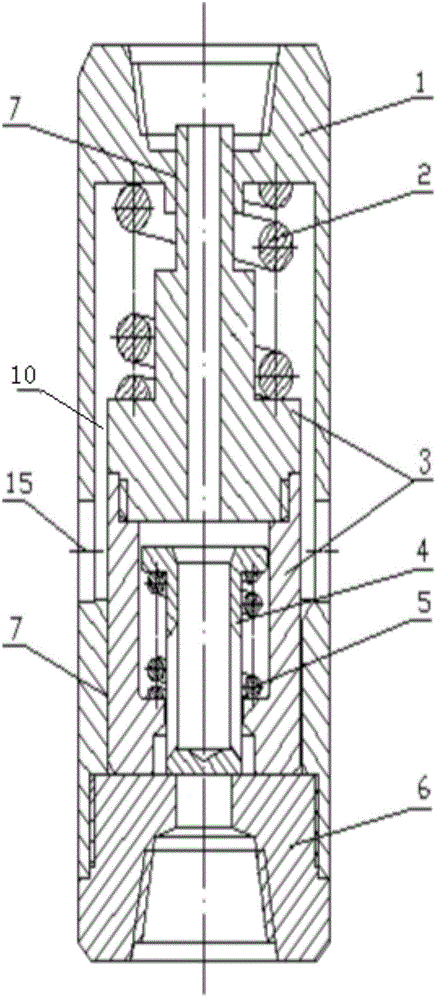

[0035] Embodiment three such as image 3As shown; the down-the-hole hammer is composed of the shell (1), the hammer spring (2), the hammer body (3), the core valve (4), the valve spring (5), and the lower joint (6) composed of the upper hammer body and the lower hammer body ; Both the shell (1) and the lower joint (6) and between the upper hammer body and the lower hammer body are rigidly connected, the structure and installation position of the hammer spring (2), core valve (4) and valve spring (5) Both are exactly the same as in Example 1; the upper part of the upper hammer body and the outer casing are dynamically sealed (7), and the lower part of the lower hammer body and the lower part of the outer casing are also dynamically sealed (7); the working fluid enters from the upper end of the outer casing (1). The drain hole (14) in the lower joint (6) is discharged, and the working fluid flow channel between them is exactly the same as that in Embodiment 1. The difference in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com