A Method for Measuring Valve Assembly Torque Relaxation

An assembly force and valve technology, applied in measuring devices, power measurement, torque measurement, etc., can solve the problems of not satisfying the static sealing specific pressure, affecting the static sealing pressure of the gasket, and reducing it, achieving high precision and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

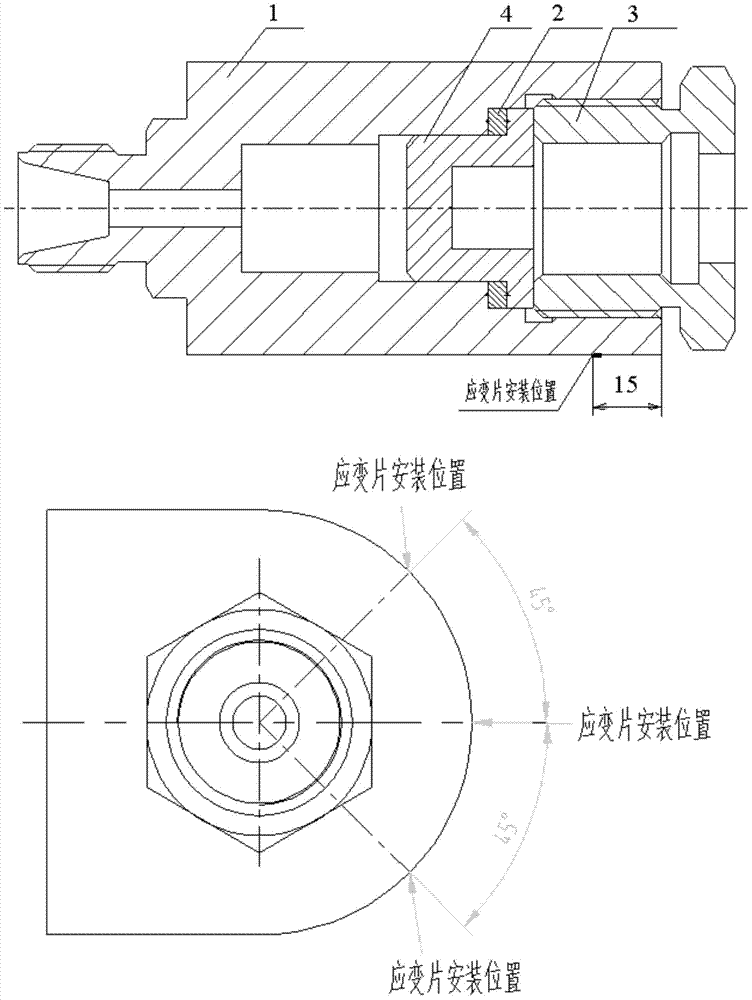

[0017] Such as figure 1 As shown, the outer sealing structure of the valve is composed of a shell 1, a gasket 2, a compression nut 3 and a compression sleeve 4; Installed in the threaded mounting hole of the housing 1, the compression nut 3 compresses the compression sleeve 4;

[0018] Three strain gauges are evenly installed on the outer surface of the housing 1 for strain measurement;

[0019] The steps of this method are:

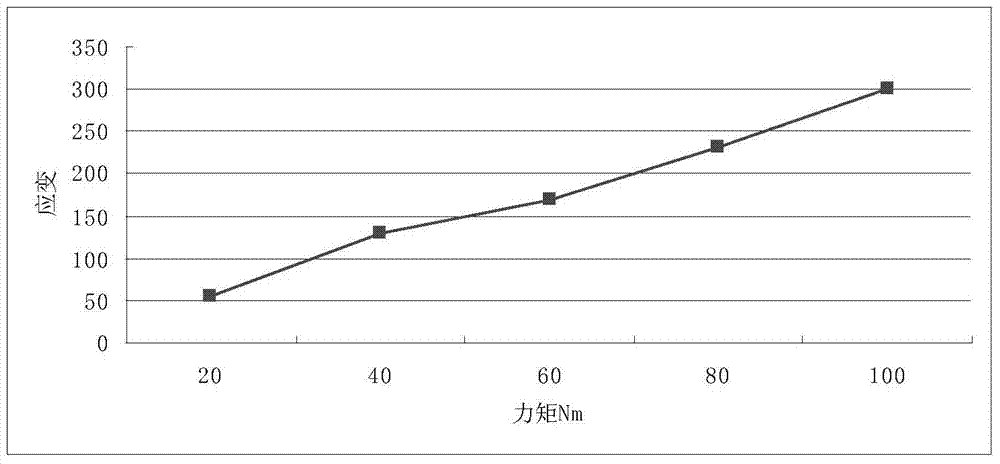

[0020] 1) Apply torques of 20Nm, 40Nm, 60Nm, 80Nm and 100Nm to the compression nut 3 in sequence, and record 3 strain values at the same time after each application, and the relationship between the strain of the shell 1 and the torque of the compression nut 3 is obtained as figure 2 shown;

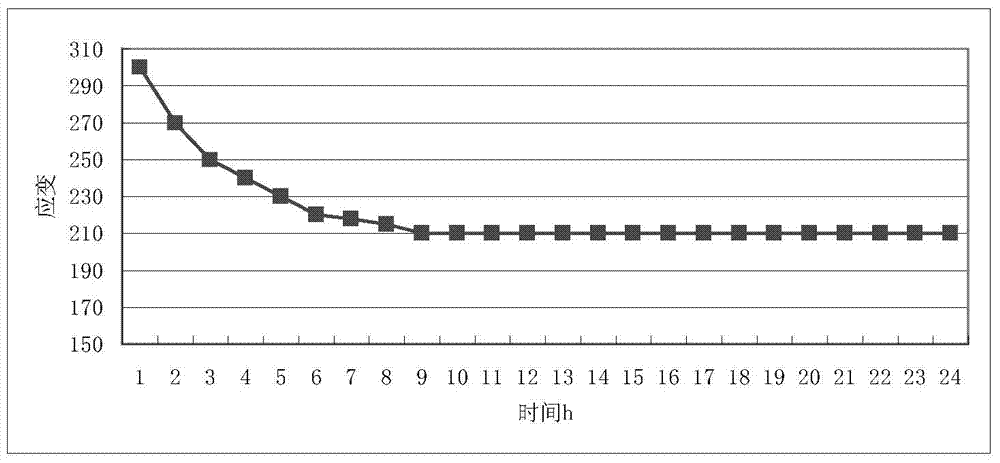

[0021] 2) Collect the calibrated strain gauges for a long time, and after 24 hours, the strain value of shell 1 decays to a stable state, and the obtained strain curve is as follows: image 3 shown;

[0022] 3) Through the calibration curve obtained in step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com