Safety door structure of power socket

A power socket and safety door technology, which is applied in the direction of circuits, electrical components, bases/shells, etc., can solve the problems of socket safety performance reduction, complicated assembly, and many components, and achieve simple structure, long service life, and low product failure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] A power socket safety door according to the present invention is described in detail in combination with specific embodiments.

[0034] In this embodiment, the reset biasing member is a spring.

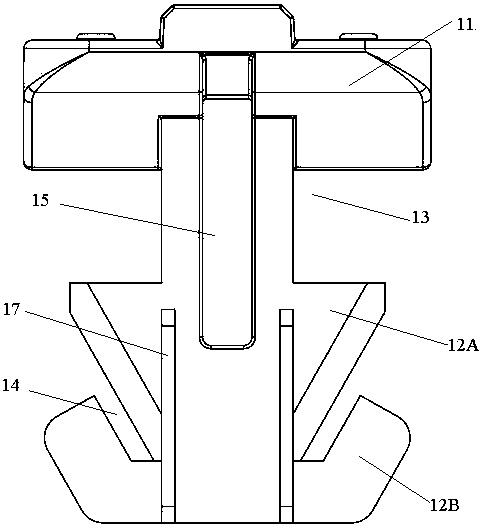

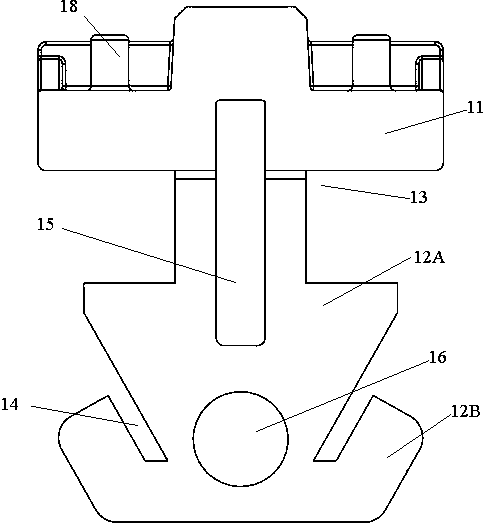

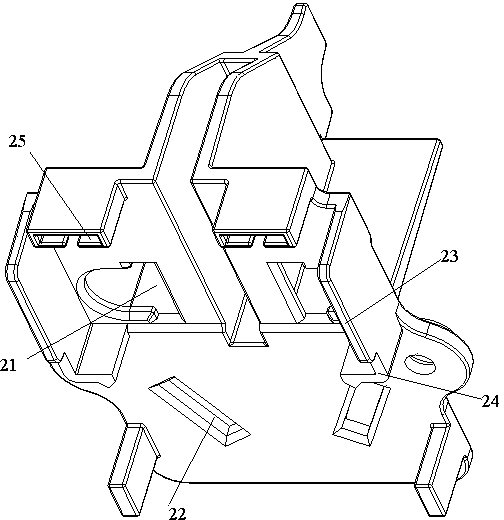

[0035] Such as Figure 1A and 1B As shown, the safety baffle 1 is a left-right symmetrical overall structure, including a main part of the baffle, and baffle parts distributed on the left and right sides of the main part of the baffle, and the baffle parts include Two-plug socket stopper 11, and the upper three-plug socket stopper 12A on the left and right sides and the lower three-plug socket stopper 12B on the left and right sides, and the two-plug socket stopper 11 on the same side and the A first slot 13 for the pins of the two plugs to pass is formed between the above three-plug jack stoppers 12A; A second slot 14 is formed between the baffles 12B for the pins on the side of the three-prong plug to pass through, and a second slot 14 for the middle pins of the three-pron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com