Pharmaceutical particle packing machine

A technology of filling machine and granules, applied in packaging, solid separation, sieving and other directions, can solve the problems of easy agglomeration of granules, unadjustable dosage of granule filling machine, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

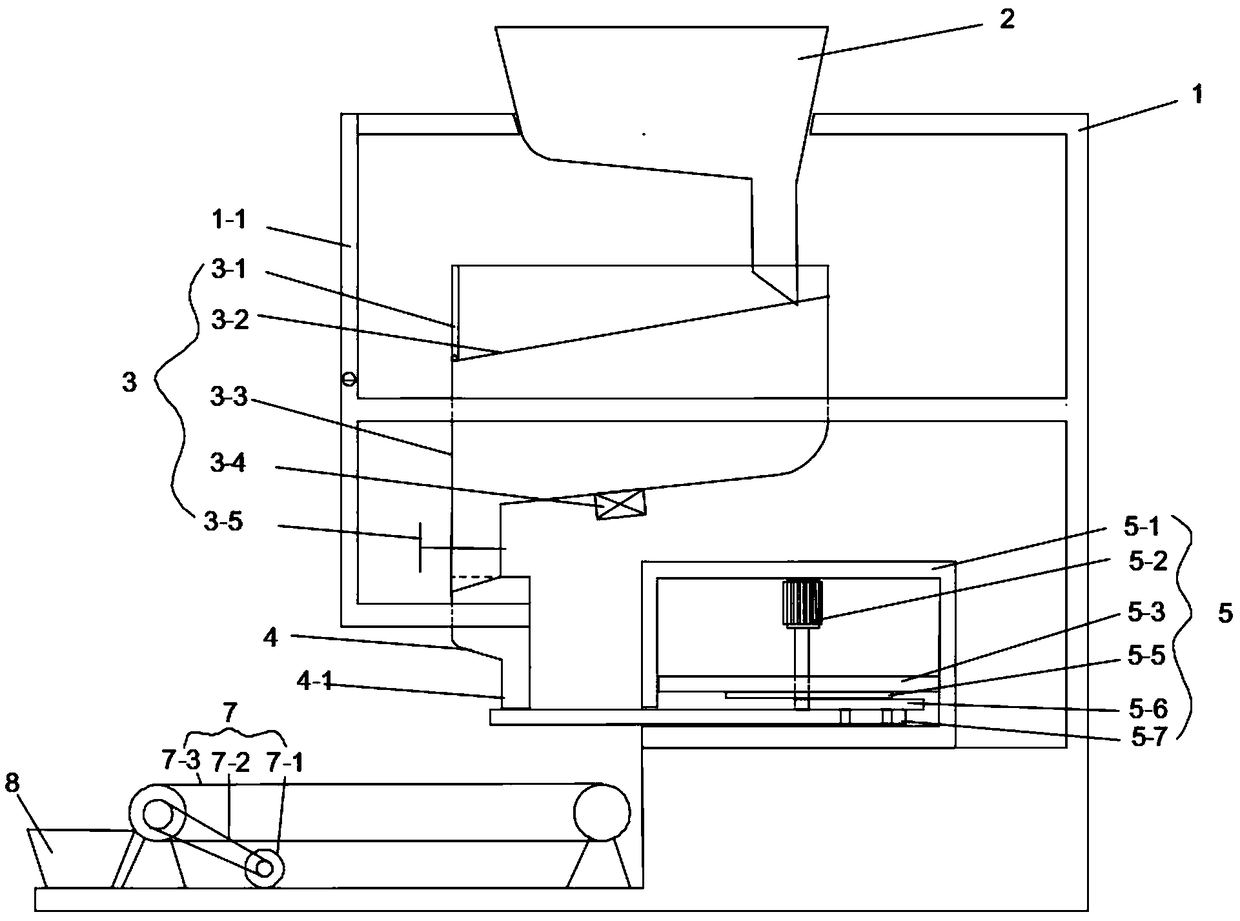

[0031] like figure 1 As shown, this embodiment includes a bracket, and also includes a feed hopper arranged on the top of the bracket, a storage and screening mechanism is provided below the feed hopper, and a discharge hopper is provided below the storage and screening mechanism. The discharge hopper is fixedly connected to the bracket, and the right end below the outlet of the discharge hopper is provided with a first adjustment mechanism, the second adjustment mechanism is provided below the first adjustment mechanism, and the left side below the discharge outlet is provided with a The conveying mechanism, the lower end of the conveying mechanism is fixedly connected to the bottom surface of the bracket, and the left end of the conveying mechanism is provided with a storage device.

[0032] In this embodiment, first close the switch valve provided on the storage hopper, then place the particles to be divided into the feed hopper, open the vibrator at the bottom of the stora...

Embodiment 2

[0034] like Figure 1-4 As described, the present embodiment is further optimized on the basis of embodiment 1, and the specific implementation scheme is as follows:

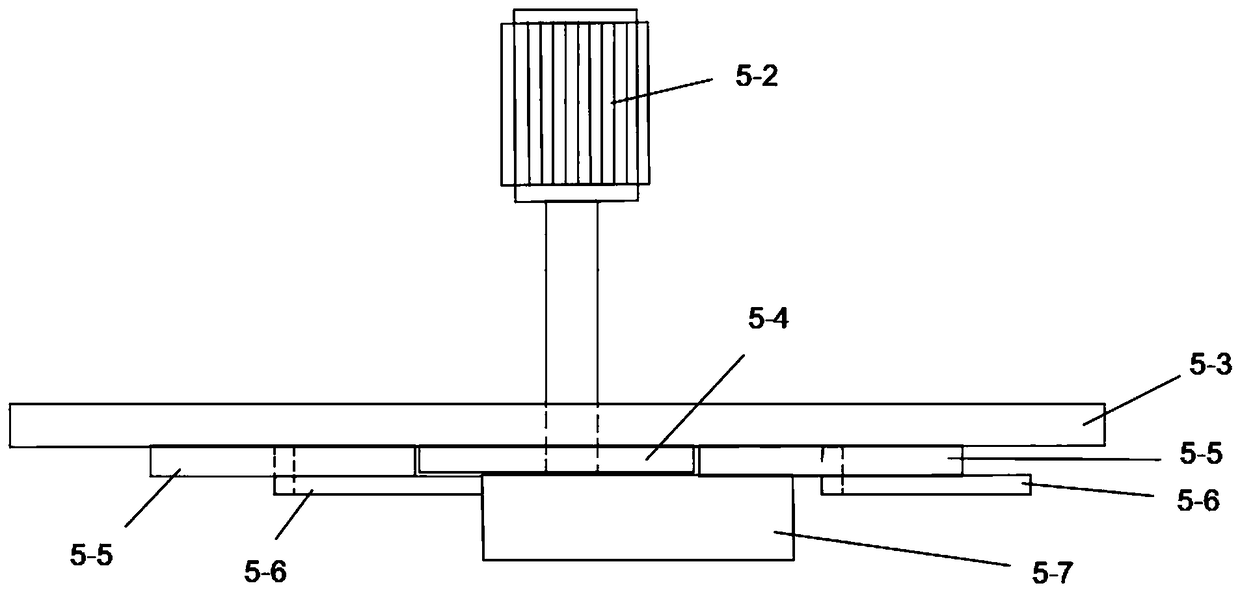

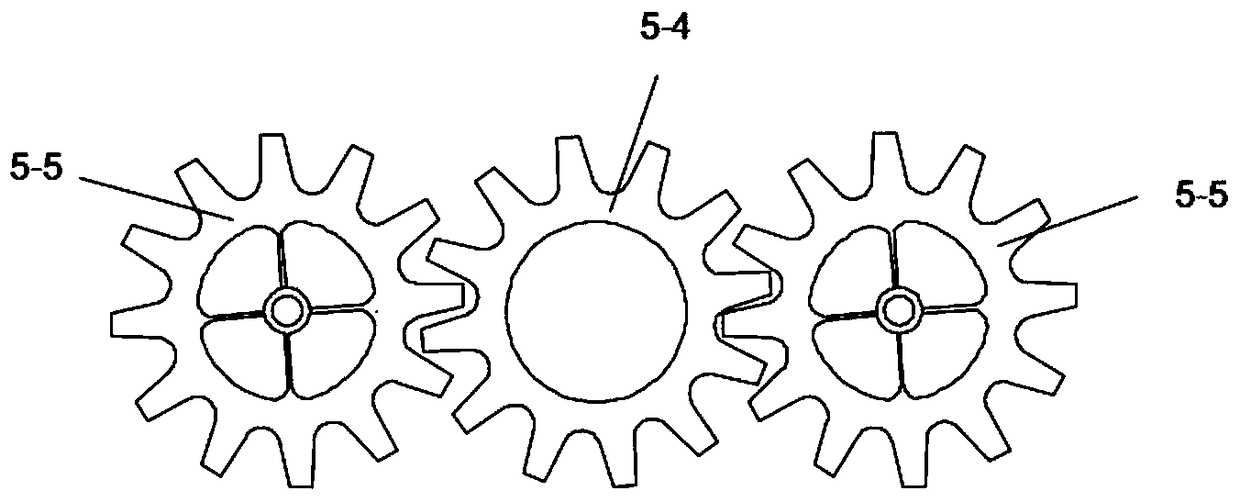

[0035] The first adjustment mechanism includes a support box, the left side of the support box is provided with an opening, the top of the support box is fixed with a first motor, the output shaft of the motor passes through the support plate and connects to the first driving gear, the second The left and right sides of a driving gear are provided with driven gears, the bottom surface of the driven gears is coaxially fixed with sector gears, the top surface of the driven gears is fixed with the support plate, and the driven gears are provided with A rack perpendicular to the line connecting the centers of the driven gears, the rack meshes with the sector gear, the rack is arranged at the bottom of the support box and can reciprocate along the bottom of the support box, the upper surface of the rack and the The ...

Embodiment 3

[0038] like Figure 5 As shown, the present embodiment is further optimized on the basis of embodiment 1, and the specific implementation scheme is as follows:

[0039] The second adjustment mechanism includes a T-shaped block arranged at the bottom of the support box, and also includes a T-shaped slot arranged on the right side of the bracket to match the T-shaped block.

[0040] In this embodiment, the second adjustment mechanism includes a T-shaped block arranged at the bottom of the support box, and also includes a T-shaped slot arranged on the right side of the bracket to match the T-shaped block, and through the T-shaped slot and the T-shaped block along the horizontal The relative sliding in the direction can adjust the distance between the support box and the discharge port, and the quantitative adjustment of different quantities can be realized by adjusting the distance between the discharge port and the support box.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com