Haemostatic dressing and production method thereof

A technology of hemostatic dressing and chitosan, which is applied in the fields of medical science, bandages, absorbent pads, etc., can solve the problems of reduced hemostatic ability of dressings, lowering the proportion of chitosan fibers, etc., and achieves both hemostatic effect and stress strength, Accelerated hemostasis speed, high stress strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

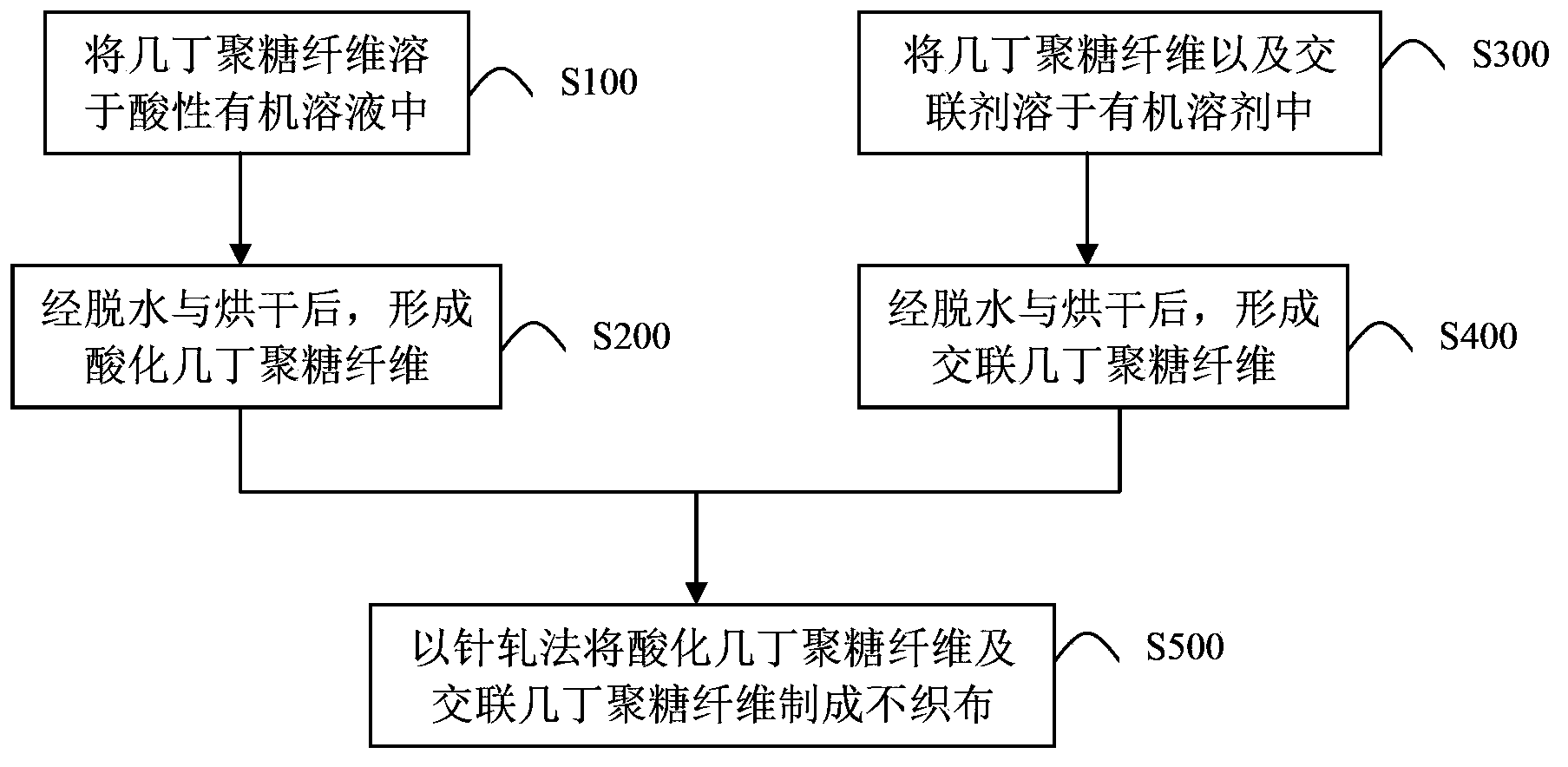

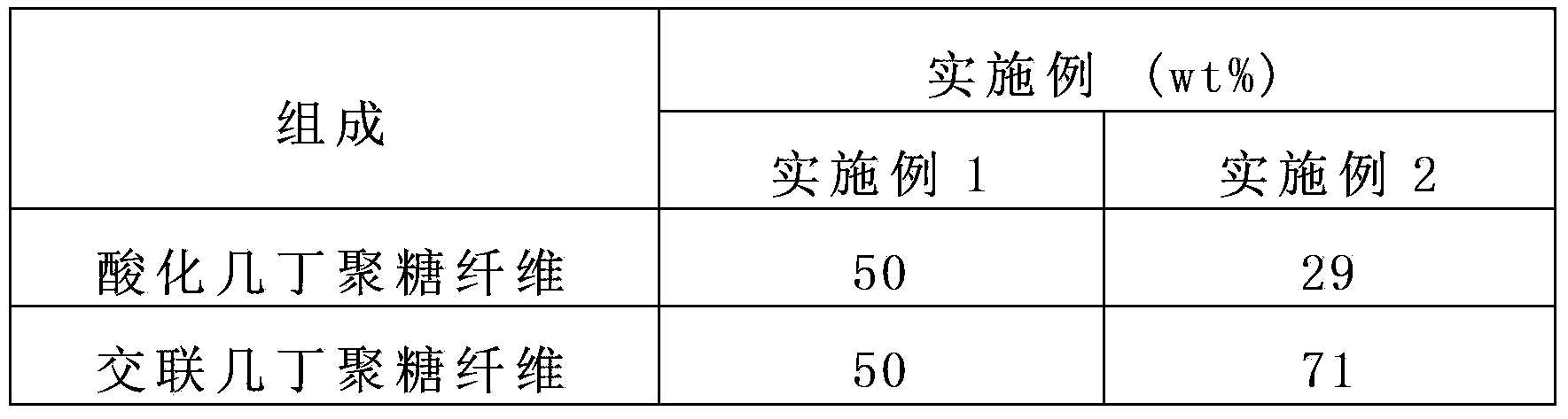

[0037] Following is the preparation of hemostatic dressing of the present invention:

[0038] 1,000 grams of acetic acid and 19,000 grams of alcohol were mixed to form an acidic organic solution (pH about 4.7), and then 300 grams of chitosan fibers (purchased from Hayes Moore, China) were dissolved in the acidic organic solution and stirred for 2 hours , forming an acidified chitosan fiber solution. Next, put the fibers into a dehydrator, centrifuge for 2 minutes, and perform dehydration. Then put the fibers into an oven, set the temperature at 75° C. and bake for 180 minutes to form acidified chitosan fibers.

[0039]300 grams of chitosan fibers (purchased from Haysmore, China) and 50 grams of crosslinking agent glutaraldehyde were dissolved in 10000 grams of 0.5% alcohol solution. After stirring and reacting for 2 hours, a cross-linked chitosan fiber solution is formed. Next, put the fibers into a dehydrator, centrifuge for 2 minutes, and perform dehydration. Then put th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com