X-axis motor base drilling jig

A technology of motor base and drilling mold, which is applied in the direction of the drilling mold used for workpieces, etc., which can solve the problems of slow clamping efficiency and low drilling position accuracy, and achieve the effect of improving clamping efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

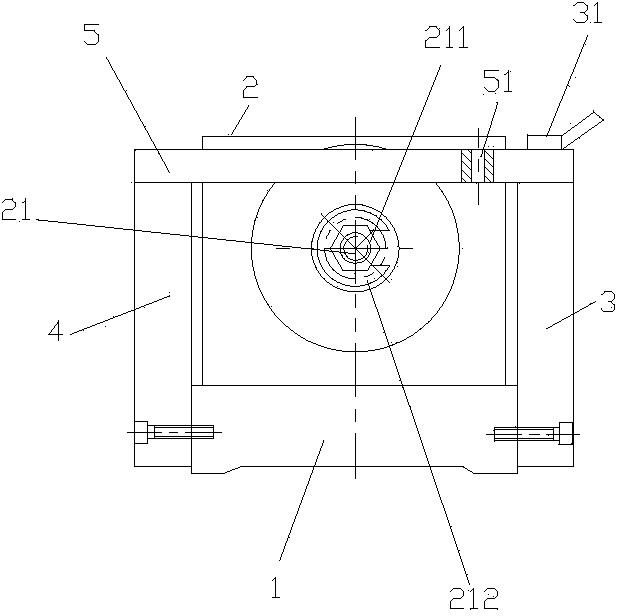

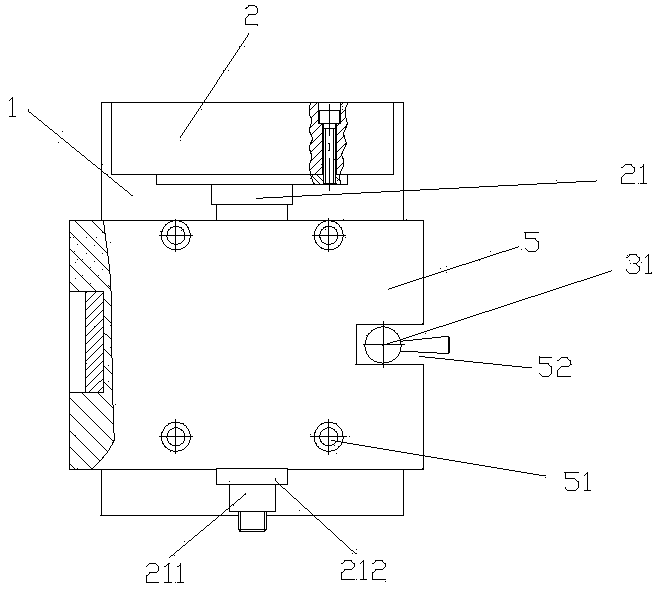

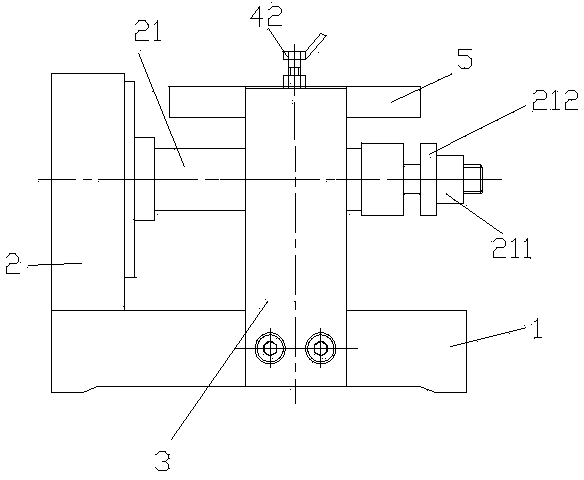

[0013] Such as figure 1 The shown X-axis motor base drilling template includes a base 1, a side plate 2 fixed on the rear end of the base 1 by screws, a first support plate 3 and a second support plate 4 fixed on the left and right ends of the base by screws , Briquetting 5. The side plate 2 is vertically placed, and a column 21 is fixed on the front end of the side plate 2. The front end of the column 21 is covered with a nut 211 for resisting the workpiece to be processed, and an opening gasket 212 is also provided between the nut 211 and the workpiece to be processed. , and be placed on the column, 212 opening pads are circular opening pads. The first support plate 3 and the second support plate 4 are placed vertically respectively, and the upper end surface of the first support plate 3 is provided with a bolt 31 with a handle, and the bolt 31 is connected to the first support plate through the groove 52 . The briquetting block 5 is a cuboid block, and is provided with se...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap