Automatic cover pressing device

An automatic capping technology, applied in packaging, flanged bottle caps, transportation and packaging, etc., can solve the problem that the bottle caps cannot meet the production requirements, the combing of bottle caps is not smooth, and the bottle caps are qualified The problems such as low efficiency can be solved, and the effect of convenient operation, high qualified rate of gland and simple structure can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Specific implementation

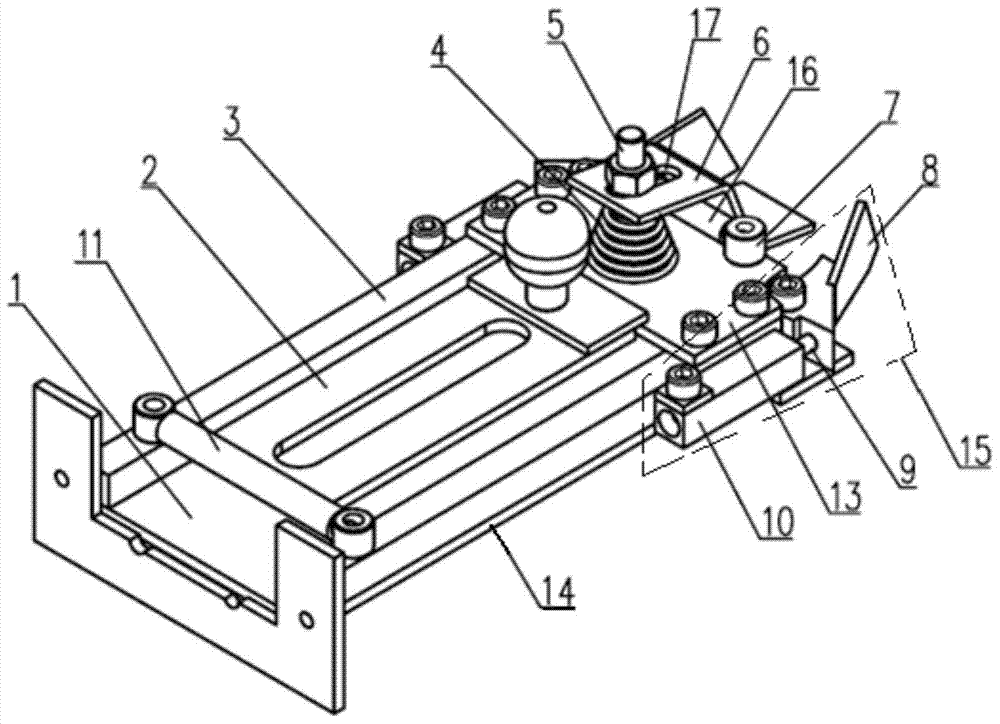

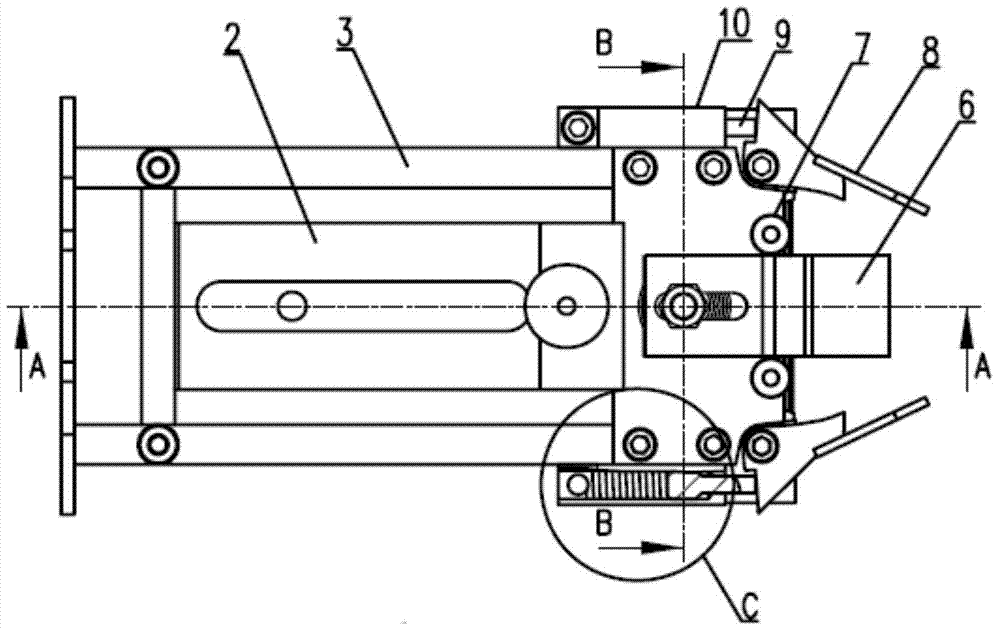

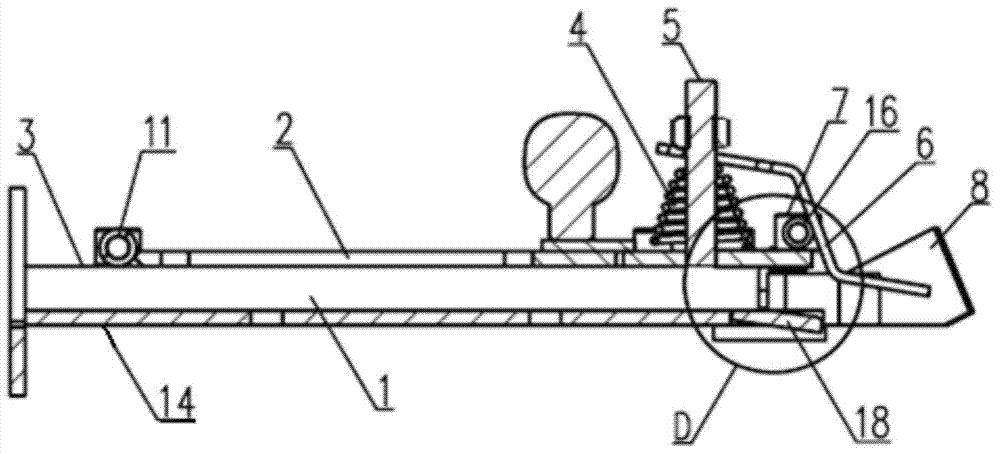

[0023] Such as figure 1 , figure 2 with image 3 As shown, an automatic capping device includes a sliding cap slot 1, a movable top cover 2, a capping buckle 6, and a lid swinging wing device 15. The sliding cover groove 1 is composed of a sliding cover bottom plate 14 and a cover blocking strip 3, and a movable top cover 2 is installed above the entrance of the sliding cover groove 1 through a sleeve 11. The purpose of this design is to allow the lid to slide smoothly into the gap and be pressed into the mouth of the bottle to realize the capping of the bottle. There is a horizontal base plate 13 above the outlet of the sliding lid groove 1 and the outlet of the sliding lid groove 1 There are flap swing devices 15 on both sides of the office. The sliding sleeve 7, the movable pin 16, and the adjusting screw 5 on the transverse base plate 13 are installed in cooperation with the gland buckle plate 6. The mounting hole 17 at one end of the gland ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com