Anti-siphon structure in oil suction inlet of lubricating oil pump

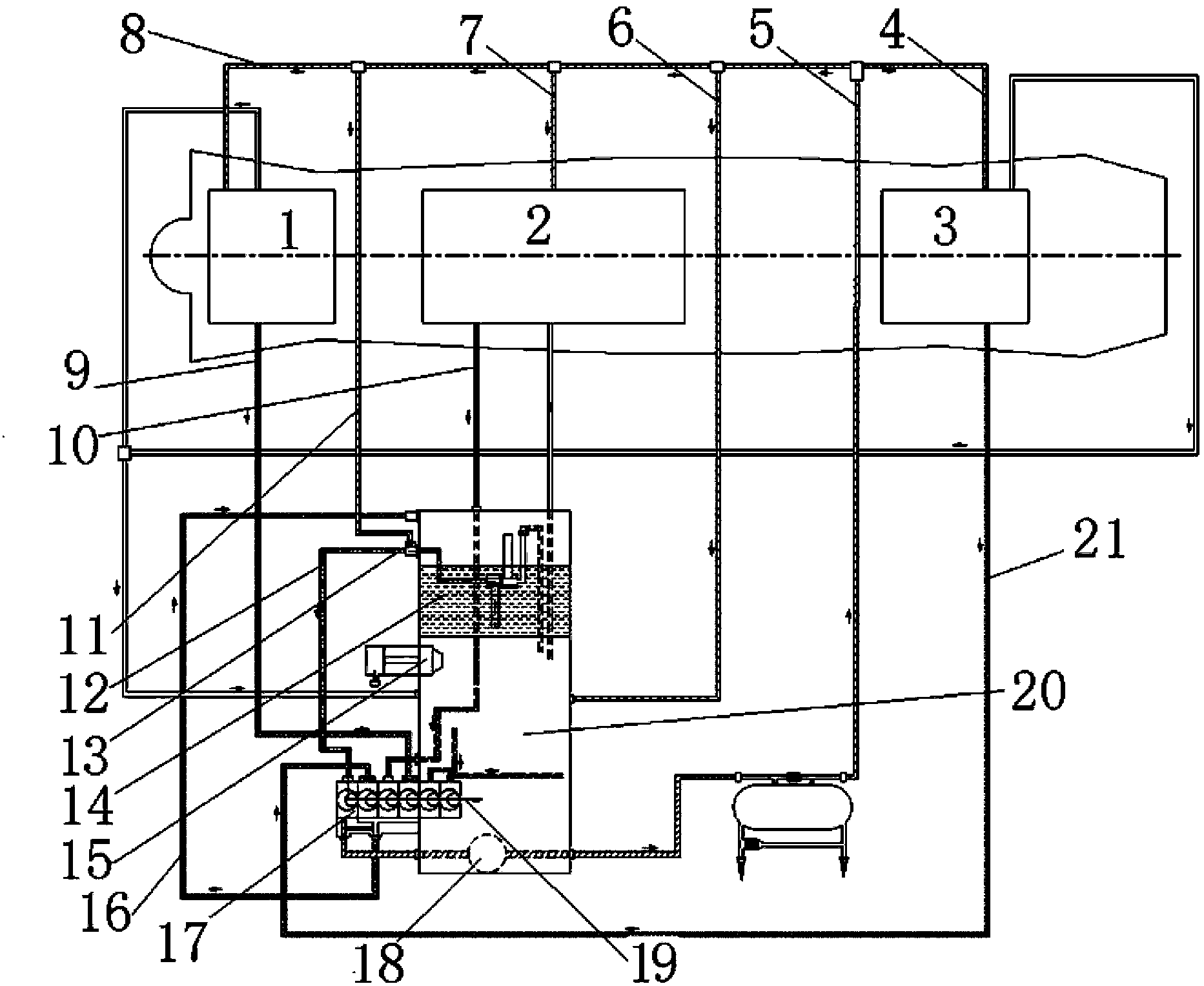

A lubricating oil pump and anti-siphon technology, applied in the direction of engine lubrication, turbine/propulsion lubrication, engine components, etc., can solve problems such as increasing the resistance of the lubricating oil system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

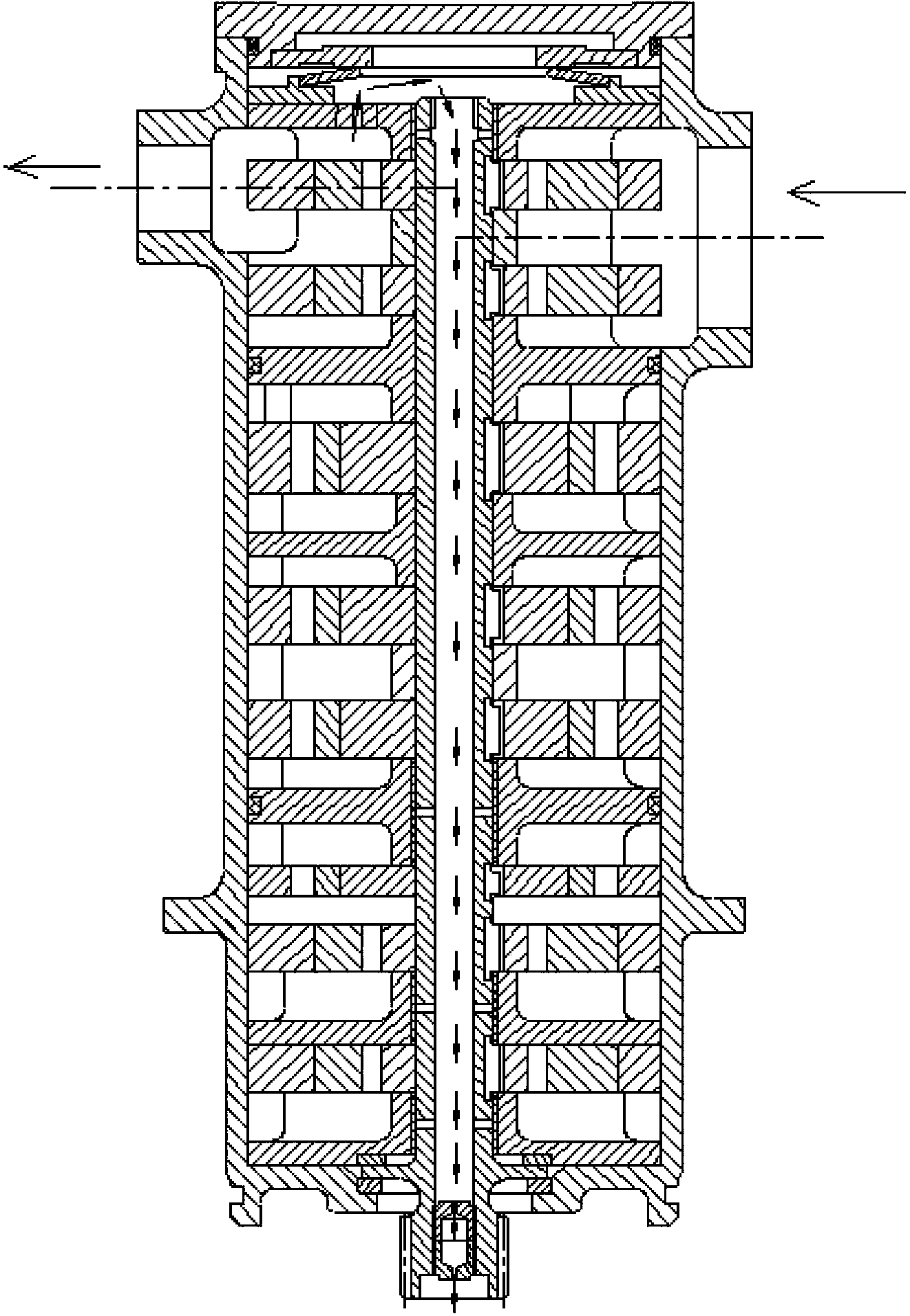

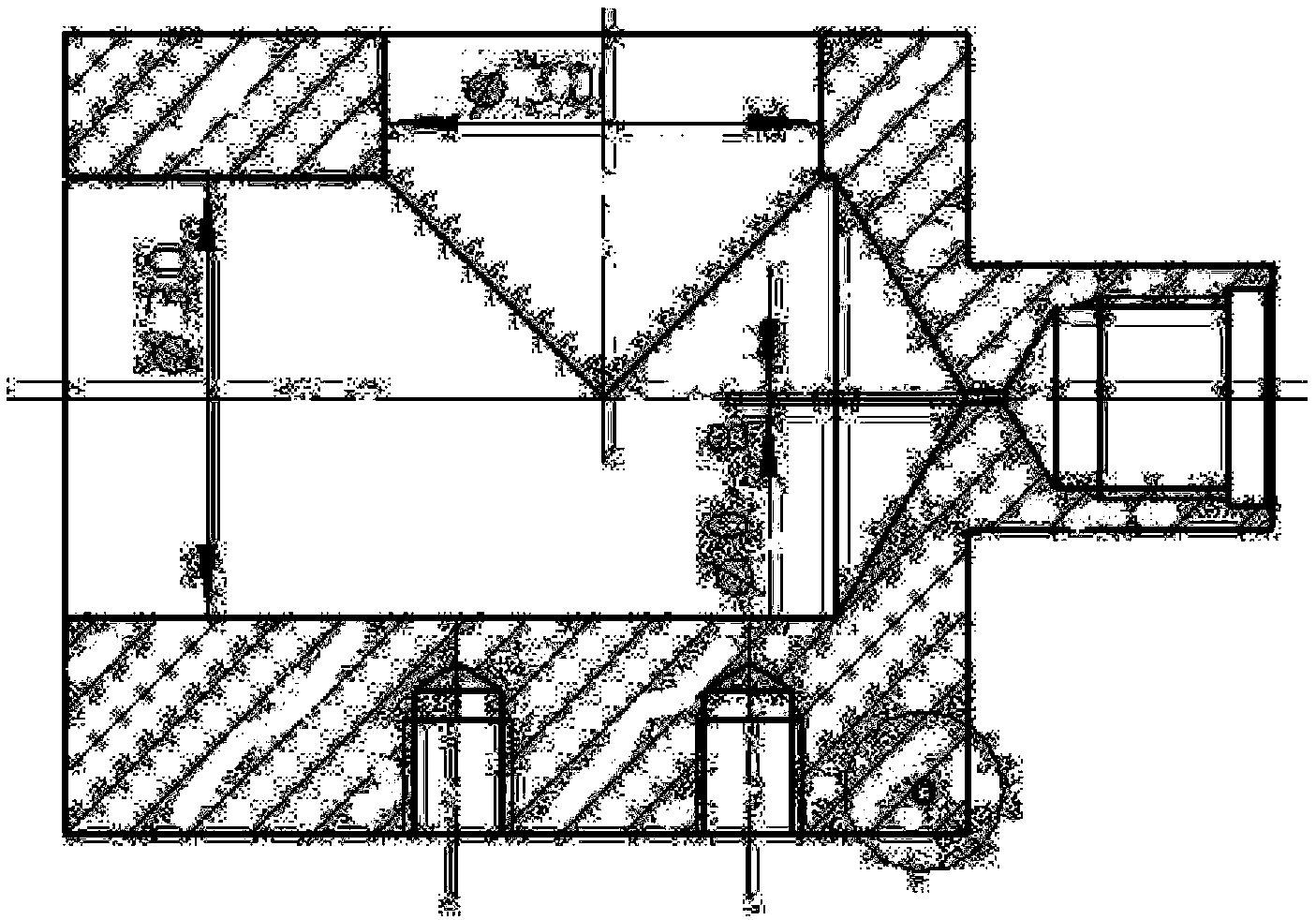

Embodiment 1

[0017] The invention provides an anti-siphon structure at the oil suction inlet of the lubricating oil pump, which is characterized in that: the anti-siphon structure at the oil suction inlet of the lubricating oil pump is specifically that the nozzles in the bearing cavities of the engine are higher than the liquid level of the fuel tank by 1 ~1.5m, while the nozzle in the accessory casing is 50-200mm lower than the liquid level of the lubricating oil tank; an anti-siphon pipeline is led from the oil suction inlet of the lubricating oil pump to the lubricating oil supply road of the front bearing cavity, and the anti-siphon pipeline is set on the liquid level of the lubricating oil tank Above, to prevent the siphon phenomenon after the engine stops, when the siphon phenomenon occurs, along with the flow of lubricating oil in the oil suction inlet pipe from the lubricating oil tank to the lubricating oil pump, the air inside the bearing cavity is introduced into this pipeline, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com