Container for oil hydraulic circuit

A technology of hydraulic circuit and container, applied in the field of hydraulic oil compensation tank, can solve the problems of insufficient prevention and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

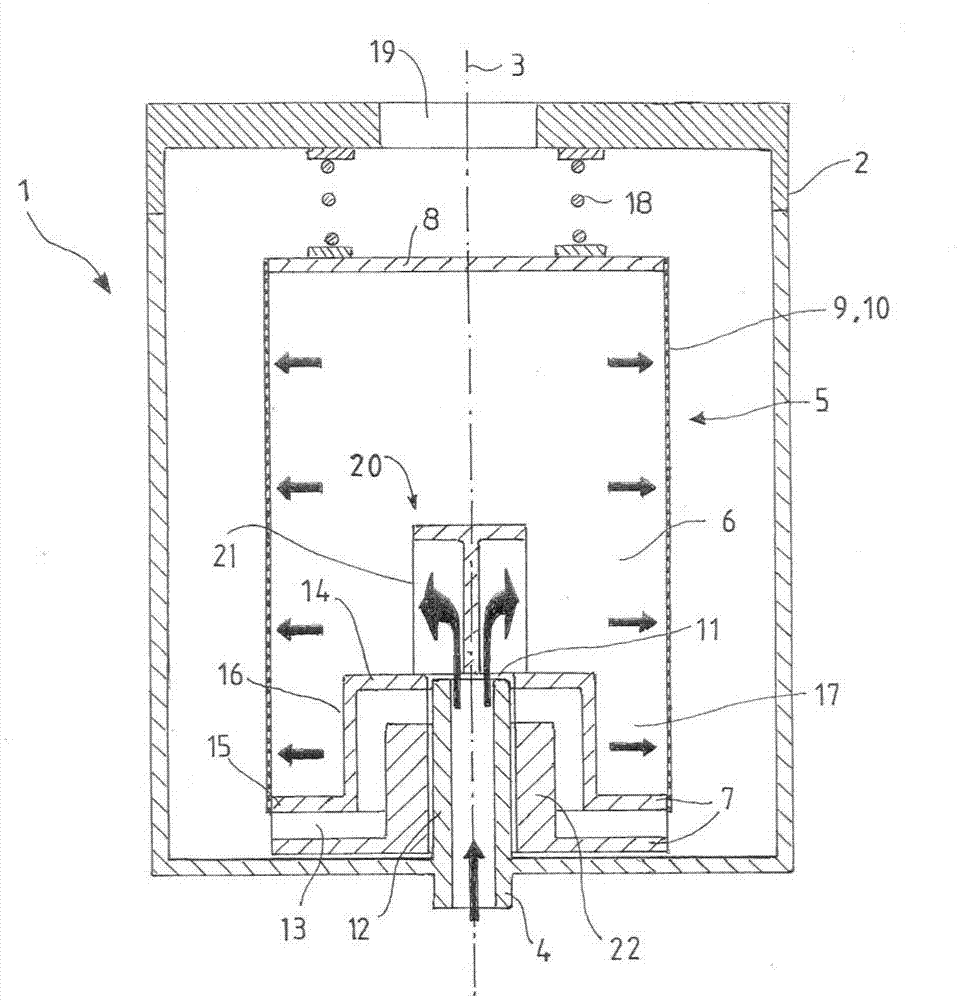

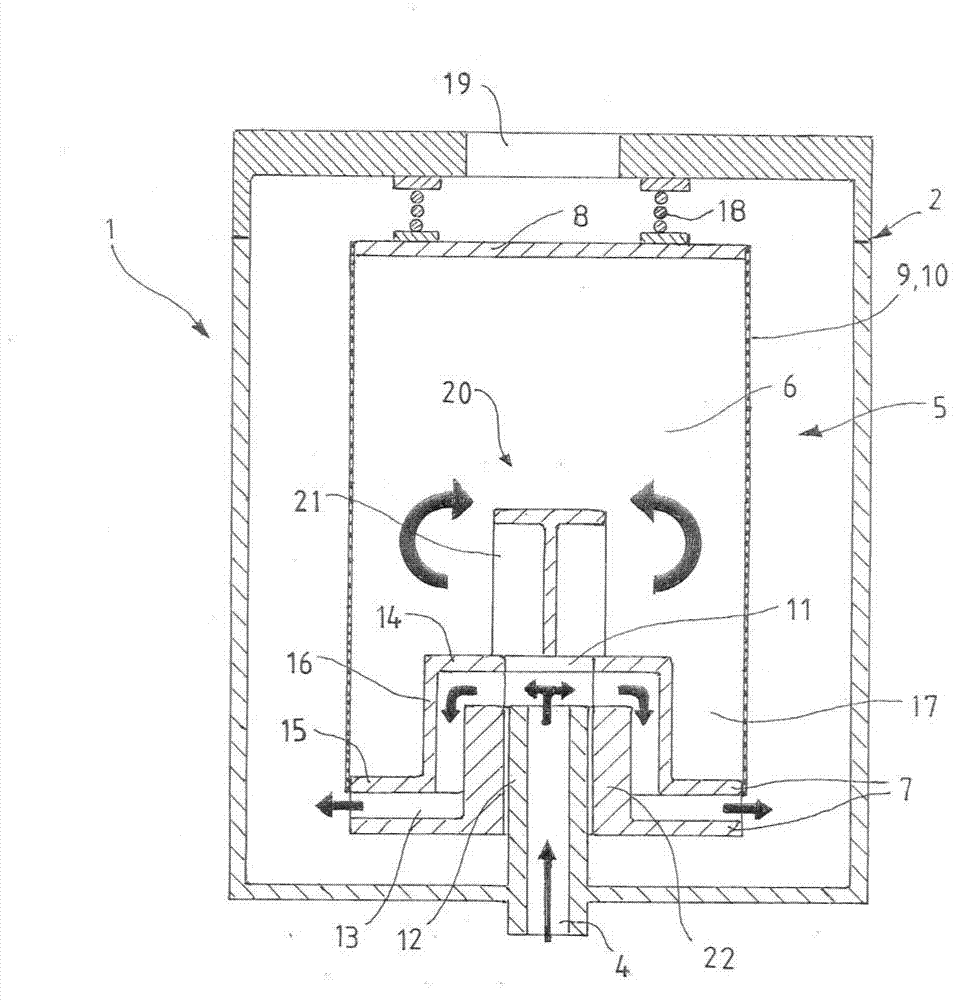

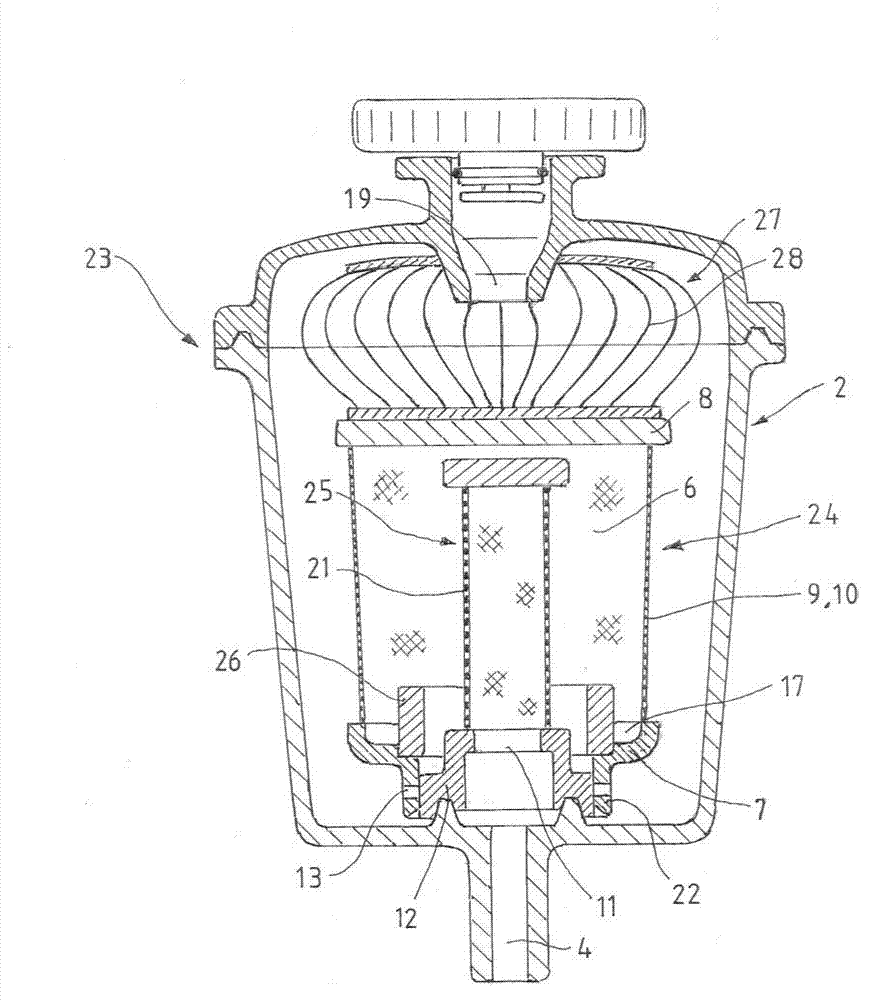

[0024] figure 1 Shows a cross-sectional side view of a first embodiment of a container 1 according to the invention for a hydraulic circuit, in particular a hydraulic oil compensation tank of a hydraulic power steering according to the invention in a first operating position. The container 1 comprises a substantially cylindrical shell 2 with a longitudinal axis 3 . Housing 2 has figure 1 Inlet 4 is shown as well as in the figure 1 Outlet not shown in , inlet 4 is used for hydraulic fluid (more specifically, hydraulic oil) from connection to container 1 but in figure 1 The hydraulic circuit, also not shown in further detail, is received into the container 1, more specifically, hydraulic fluid is received from the hydraulic circuit of the hydraulic power steering device into the container 1, and the outlet is used to discharge the hydraulic fluid to the container 1 hydraulic circuit.

[0025] From figure 1 As seen in more detail in , the container 1 comprises at least one f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com