Torsion experiment testing device under hot vacuum environment

A test device and thermal vacuum technology, which is applied in the direction of measuring device, machine/structural component testing, instruments, etc., can solve the problems of difficult operation and test influence of no-load characteristic test of the test object, and achieve convenient no-load characteristic test. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

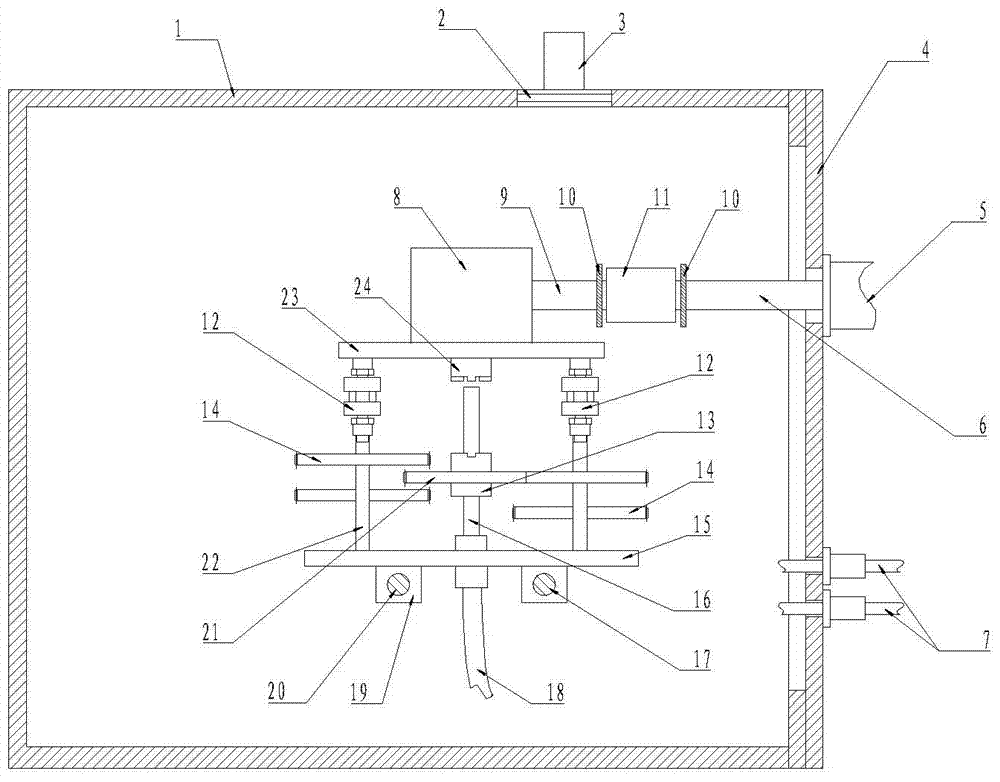

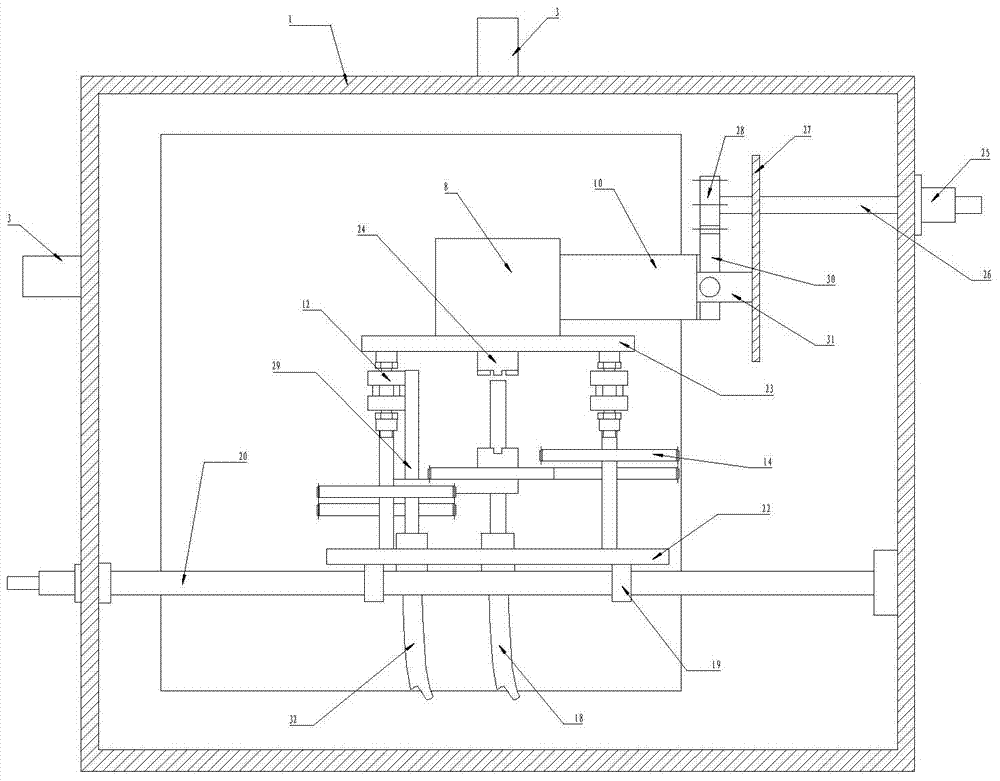

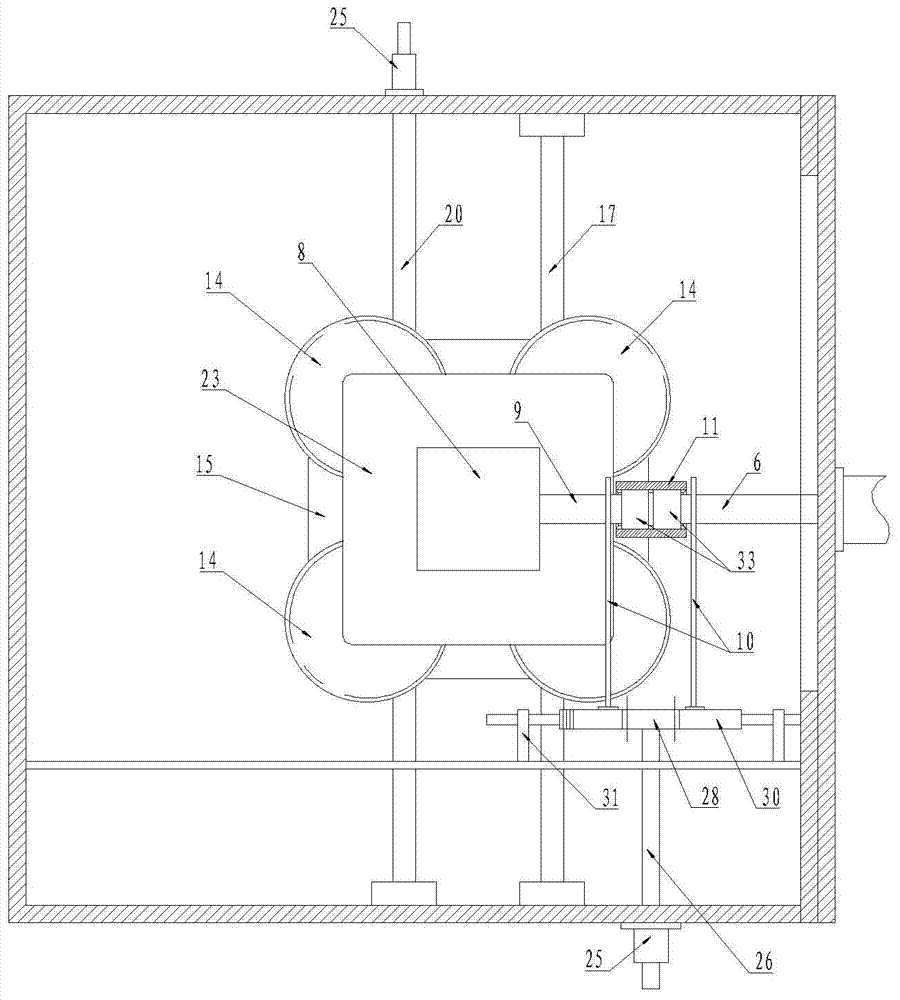

[0039] combined with Figures 1 to 3 , a torsion experiment test device in a thermal vacuum environment, including an adjustment base, an observation group 3, a lever device, a connecting spline, and a thermal vacuum box. The thermal vacuum box also includes a box cover 4 and a box body 1 , the box body 1 is sealed by the box cover 4 , and the magnetic fluid seal transmission shaft 6 passes through the box cover 4 . The adjusting base is installed in the thermal vacuum box, the connecting spline connects the output shaft 9 of the test piece and the magnetic fluid seal transmission shaft 6, the lever device is fixed in the thermal vacuum box and the paddle acts on the connecting spline On the key, the observation group 3 is installed on the top and side of the thermal vacuum box and is opposite to the side of the output shaft 9 of the test piece.

[0040] The observation group includes a high-resolution camera 3 and an observation window 2 .

[0041] The adjusting machine bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com