Blocked polyisocyanate compound

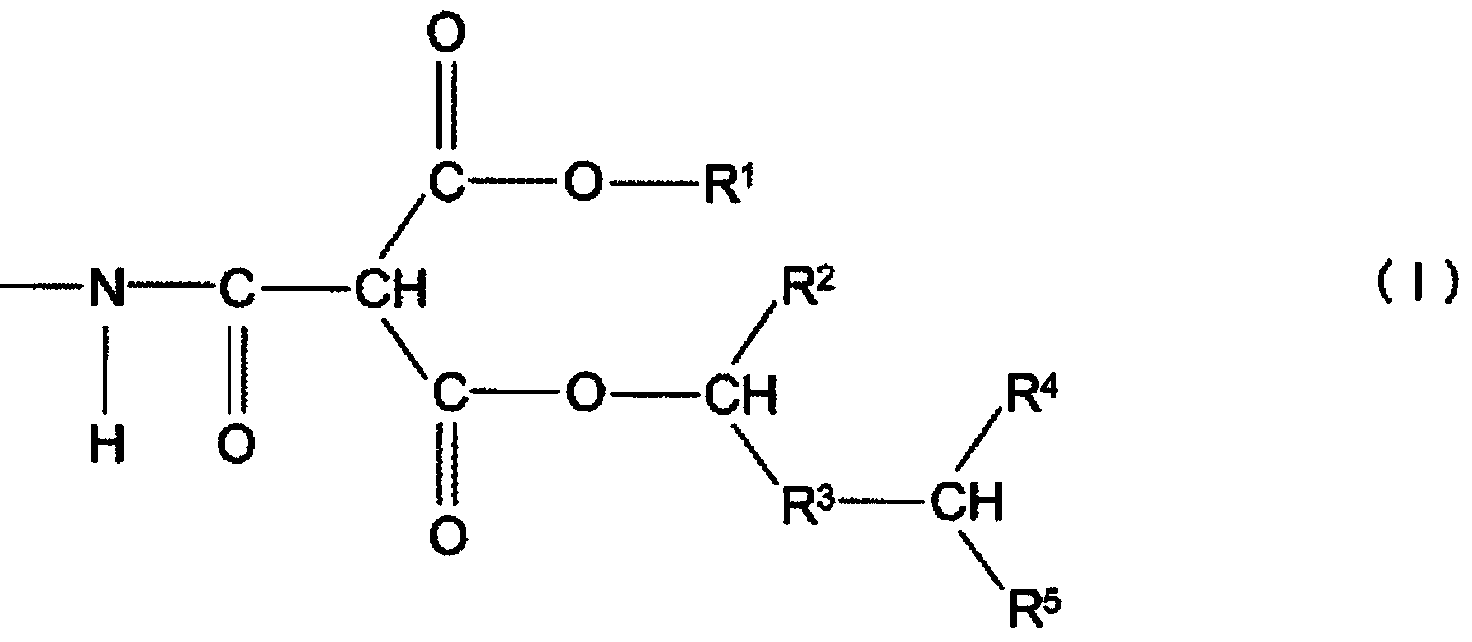

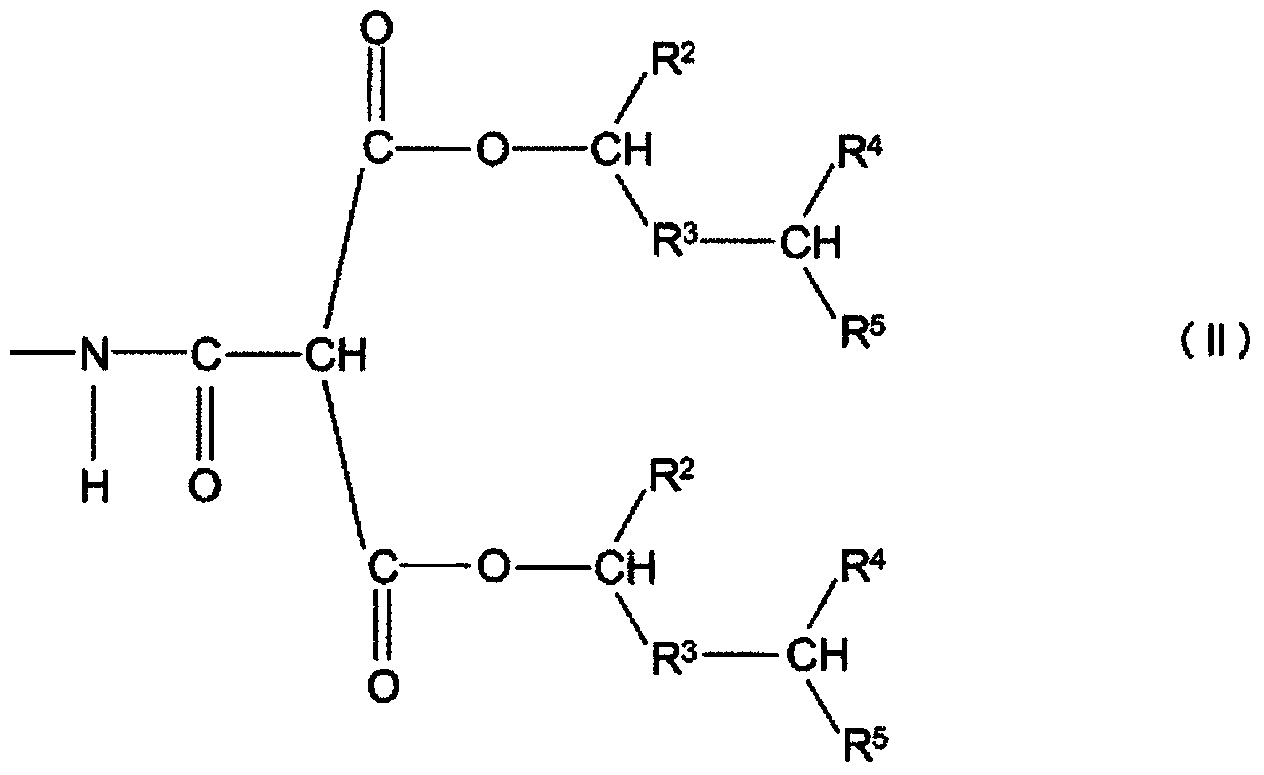

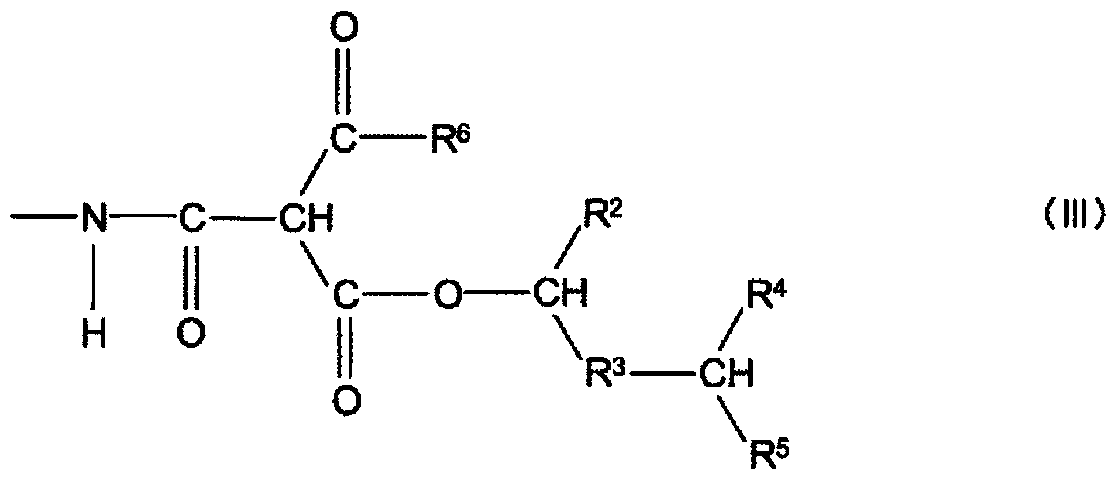

一种嵌段异氰酸酯、多异氰酸酯的技术,应用在聚脲/聚氨酯涂料、涂层等方向,能够解决水性涂料固化性降低、涂膜附着性降低、贮存稳定性降低等问题,达到平滑性及鲜映性优异、优异附着性、贮存稳定性优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0416] "SUMIDURN-3300" (trade name, Sumika Bayer Urethane Co., Ltd., polyisocyanate containing an isocyanurate structure derived from hexamethylene diisocyanate, solid content about 100%, isocyanate group content rate 21.8%) 1610 parts, "Uniox M-550" (manufactured by NOF Corporation) , polyethylene glycol monomethyl ether, average molecular weight about 550) 275 parts and 2,6-di-tert-butyl-4-methylphenol 0.9 parts, mixed thoroughly, and heated at 130°C for 3 hours under nitrogen flow.

[0417] Then, 550 parts of ethyl acetate and 1150 parts of diisopropyl malonate were charged into the above-mentioned reaction vessel, and while stirring under nitrogen flow, 14 parts of 28% methanol solution of sodium methylate were added to the above-mentioned reaction vessel, and at 65 Stir at °C for 8 hours. The amount of isocyanate in the obtained resin solution was about 0.1 mol / kg. 3110 parts of 4-methyl-2-pentanol were added to the above-mentioned reaction vessel, and the solvent was d...

Embodiment 2

[0419] Change 275 parts of "UnioxM-550" to 275 parts of "UnioxM-400" (manufactured by NOF Corporation, polyethylene glycol monomethyl ether, average molecular weight about 400), and change the amount of diisopropyl malonate to 1120 Parts, the amount of 4-methyl-2-pentanol was 3040 parts, in addition, according to Example 1, 4870 parts of a blocked polyisocyanate compound (BN-2) solution were obtained. The simple trap contains 570 parts of isopropanol. The solid content concentration of the blocked polyisocyanate compound (BN-2) solution was about 60%. In addition, the amount of isocyanate in the resin solution before adding 4-methyl-2-pentanol was about 0.1 mol / kg.

Embodiment 3

[0421] In addition to 275 parts of "UnioxM-550", 25 parts of "PEG#600" (manufactured by NOF Corporation, polyethylene glycol, average molecular weight about 600) were added to change the amount of diisopropyl malonate to 1140 parts , In addition to changing the amount of 4-methyl-2-pentanol to 3080 parts, according to Example 1, 4930 parts of a blocked polyisocyanate compound (BN-3) solution were obtained. The simple trap contains 580 parts of isopropanol. The solid content concentration of the blocked polyisocyanate compound (BN-3) solution was about 60%. In addition, the amount of isocyanate in the resin solution before adding 4-methyl-2-pentanol was about 0.1 mol / kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com