Ball bearing units for hubs

A technology of ball bearings and hubs, which is applied to bearing components, shafts and bearings, mechanical equipment, etc., can solve problems such as loss of seal interference, shortened bearing life, and degradation of lubricating oil, so as to avoid the influence of torque, good sealing effect, The effect of guaranteed life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

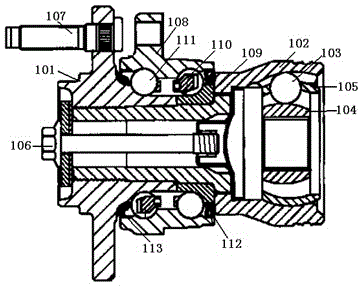

[0031] see figure 1 , shows the ball bearing device for the wheel hub of the present invention.

[0032] The ball bearing device for the wheel hub is used on the wheel hub 101 of the wheel. The outer edge of one side of the wheel hub 101 is provided with a hub bolt 107, and the other side is connected with a constant velocity connector 102. The constant velocity connector 102 is equipped with There is a hole inserted by the drive shaft. There are a plurality of rolling balls 103 and a rotatable connecting inner ring 104 and outer ring 105 for holding the balls 103 outside the hole. One end of the driving shaft 103 is provided with an inner ring. thread.

[0033] A fixing bolt 106 protrudes into the hub 101 from one side thereof, and the fixing bolt 106 has an external thread matched with the internal thread of the connecting portion 105 .

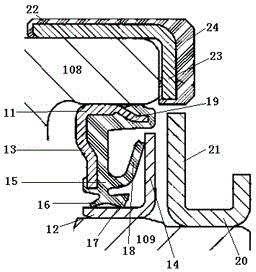

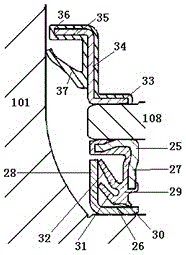

[0034] The outside of the middle part of the hub 101 is provided with an outer ring 108 fixed to the vehicle body, and a positioning rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com