Sensor molding plastic extruder hopper for observing material conveying condition

A technology of conveying situation and extruder, applied in the field of sensor forming extruder hopper, it can solve the problems of heavy workload of workers and troublesome material replacement, and achieve the effect of less extra operation, avoiding scattering, and facilitating the collection of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

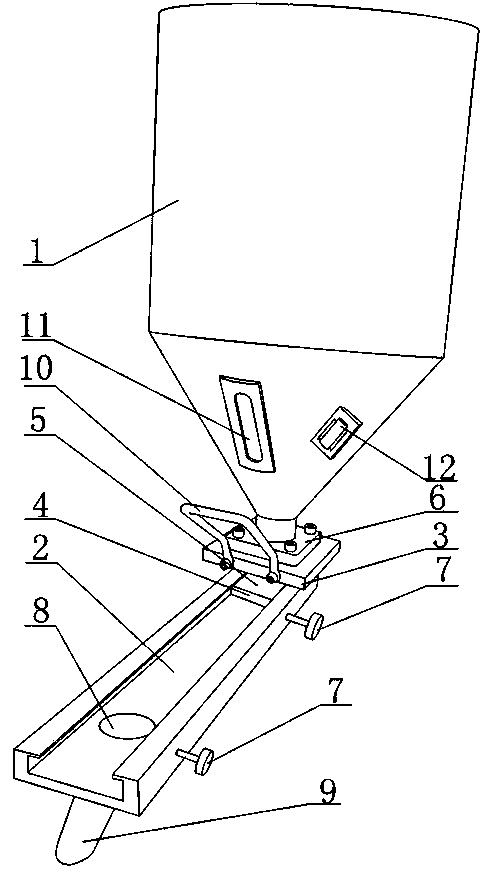

[0020] Such as figure 1 As shown, the sensor molding extruder hopper for observing material conveying conditions of the present invention includes a hopper body 1, which includes a cylindrical storage barrel, and a funnel-shaped discharge structure is connected to the bottom of the storage barrel. The discharging structure is provided with an observation window 11 and a vibration motor 12. The observation window 11 is made of commonly used transparent materials; it also includes a chute 2 fixedly installed on the extruder. The chute is a rectangular parallelepiped as a whole and has an opening on its surface. The inside is a cavity. The internal width of the chute 2 is greater than its opening width. The cross section of the chute 2 is "concave". The bottom of the chute 2 is provided with a feed port connected to the extruder, which is installed in the chute 2. There is a lower slider 4, two locking bolts 7 are provided on the side of the chute 2, and the two locking bolts 7 co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com