Method of manufacturing contact lens and contact lens

A contact lens and lens technology, applied in glasses/goggles, optics, instruments, etc., can solve the problems of limited lens effect, the need for expensive instruments, and easy scratching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In the following description, numerous specific details are included to provide a thorough understanding of embodiments of the invention. The present invention will be described in detail below with its preferred embodiments and the accompanying drawings. It should be understood that all the preferred embodiments in the present invention are for illustration purposes only, and are not intended to limit the present invention. Those skilled in the art will also understand that the present invention does not require one or more of the specific details, or other particular methods, to be practiced. The present invention can be applied to various contact lenses, which will be described below.

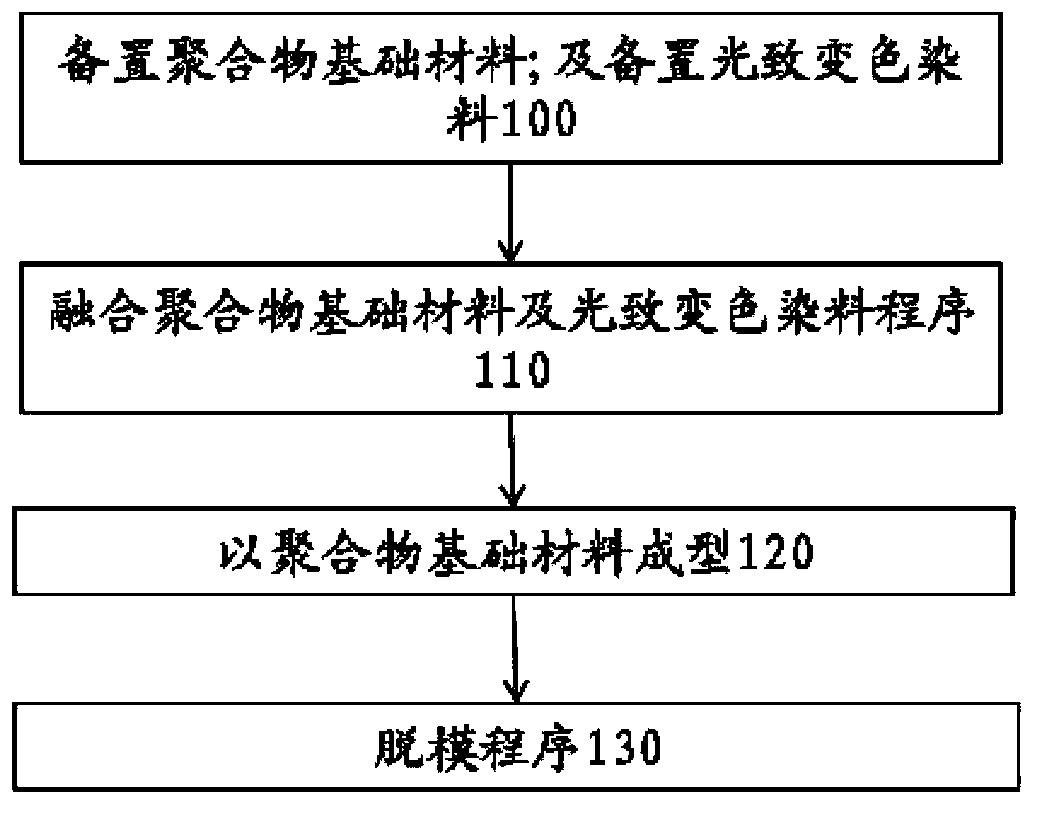

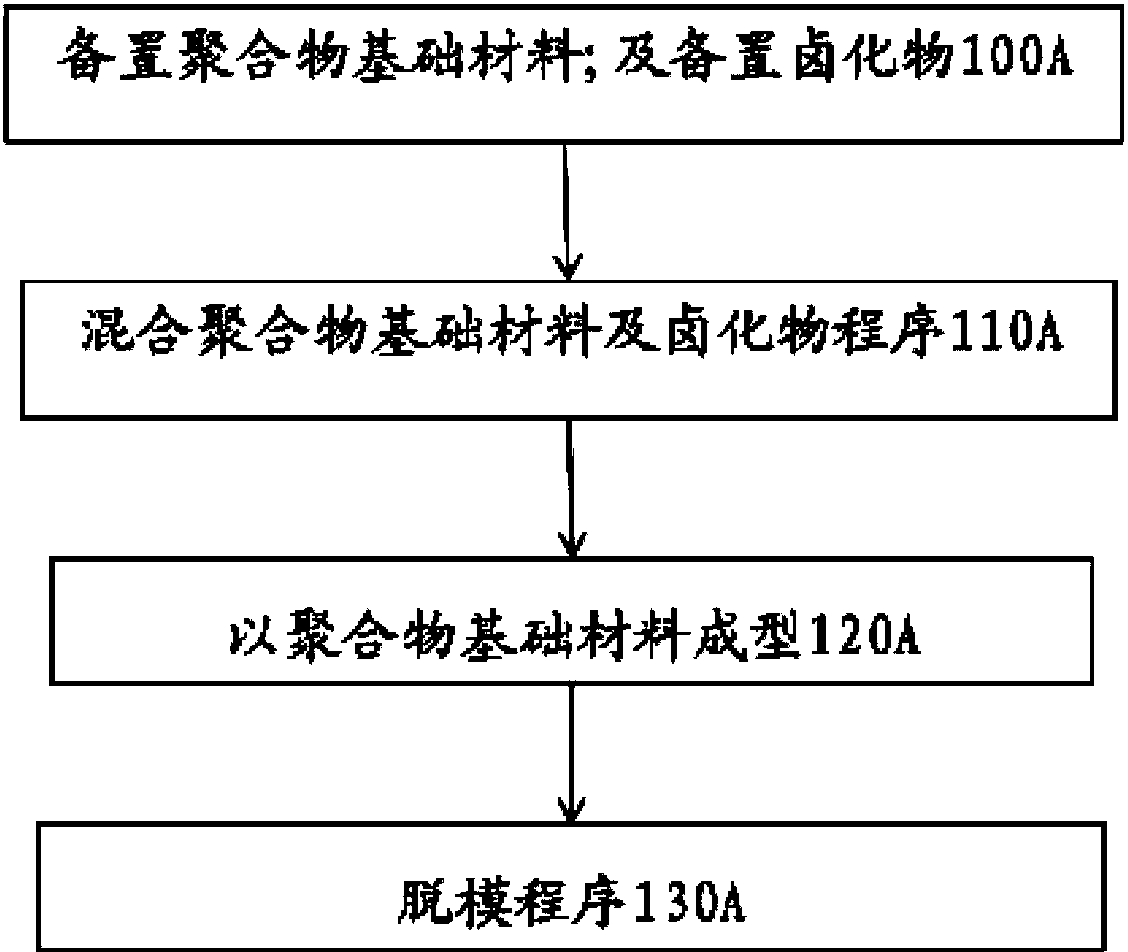

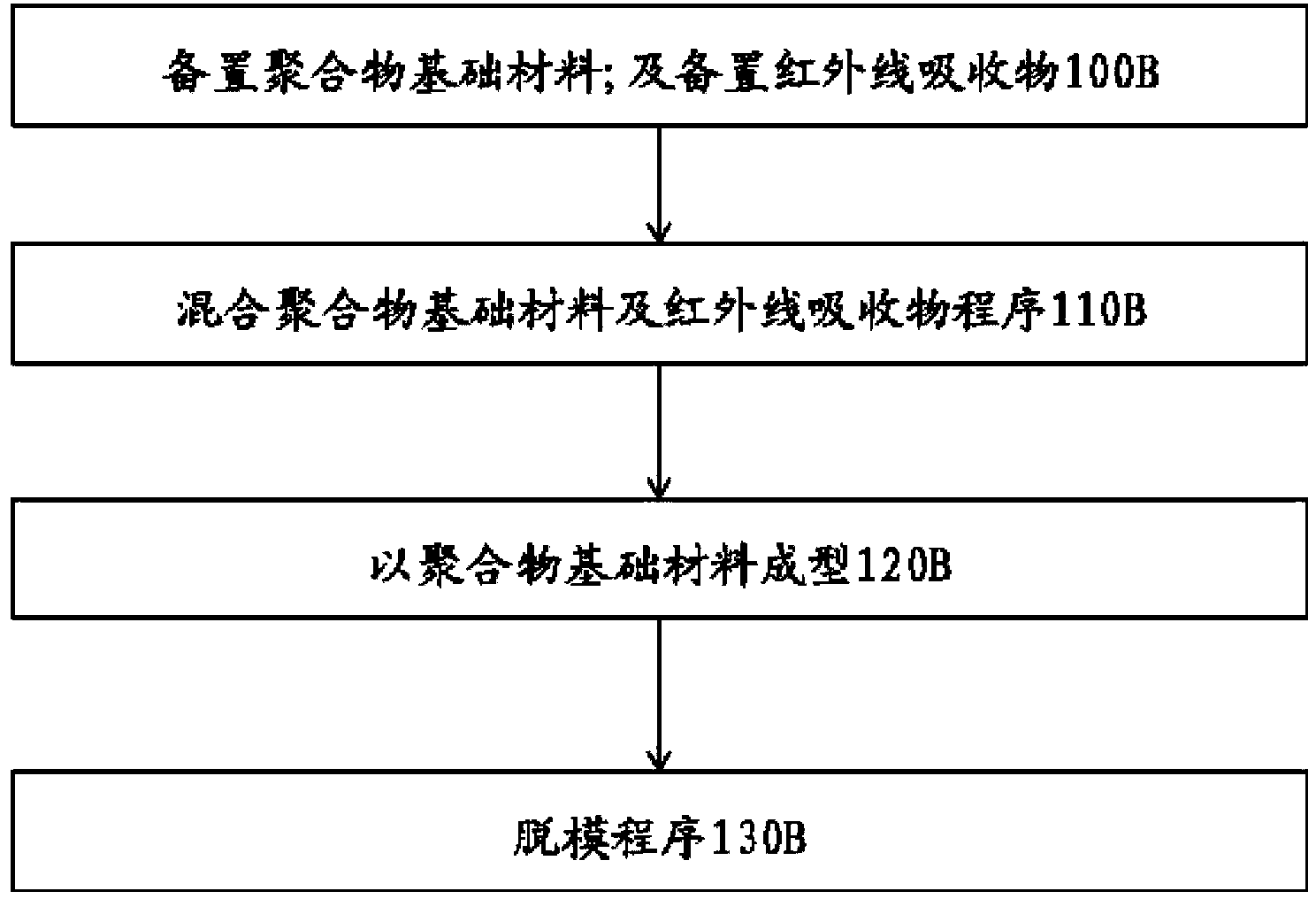

[0024] The production process of the contact lens of the present invention can use molds to make contact lens lenses, including injection molding or rotation molding. Injection molding is suitable for short-term disposable lenses or medical use. The rotary molding method is to injec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transparency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com