Nano-composite film with infrared absorption function and manufacturing method and application thereof

An infrared absorption and nanocomposite technology, applied in textiles and papermaking, fiber types, fiber processing, etc., can solve the problems of unresearched infrared absorption properties, such as the film-forming properties of spinning dope, and achieve a wide infrared absorption band and strong capillary force. , the effect of high infrared absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

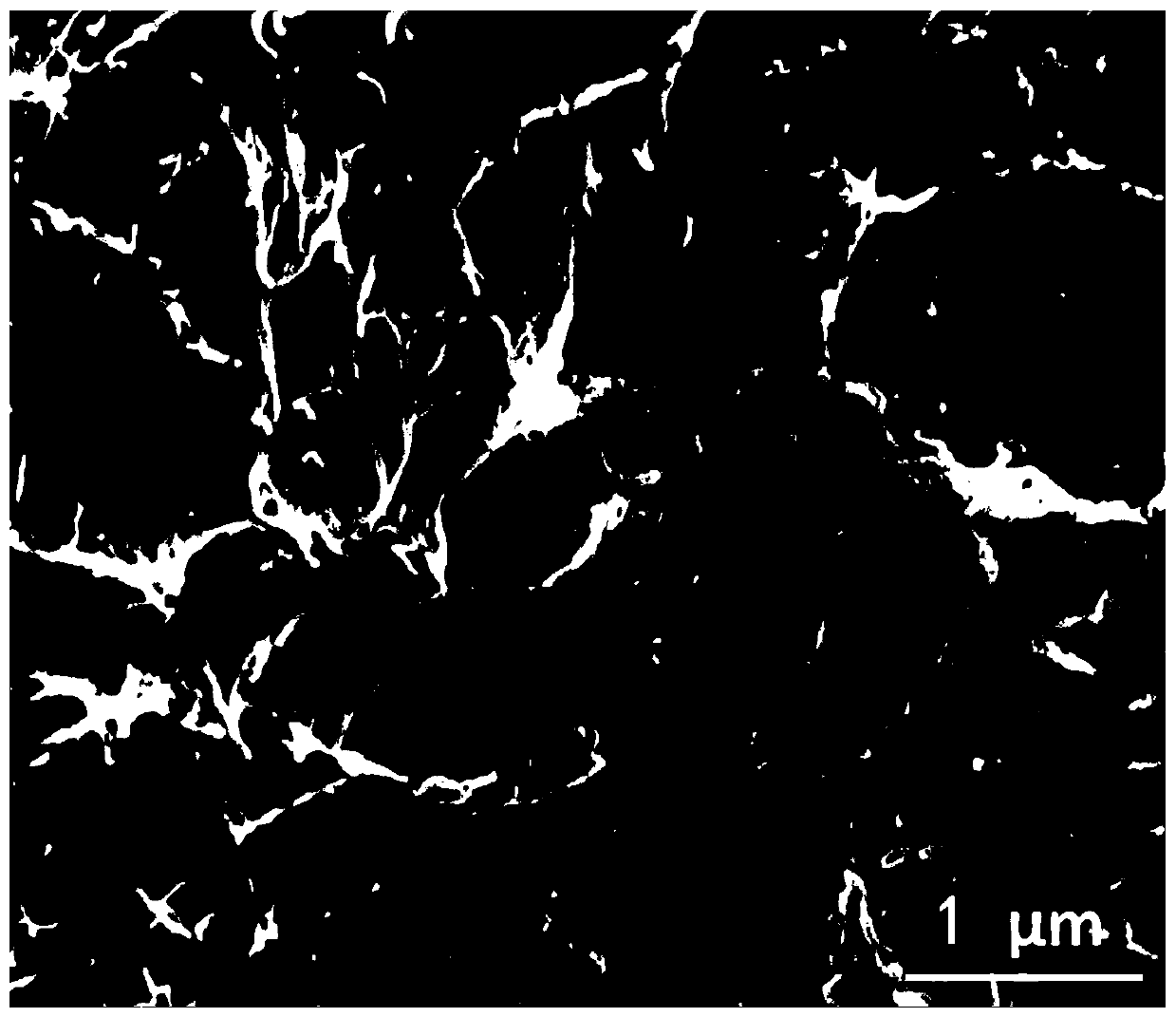

[0044] Prepare a polyethylene glycol aqueous solution with a mass fraction of 30%, with a thickness of 200 μm, a porosity of 95%, and a density of 29 mg / cm 3 1. The aramid nanofiber porous film with a thermal conductivity of 0.036W / m·K is placed in an aqueous solution of polyethylene glycol, taken out after standing for 12 hours, the excess aqueous solution of polyethylene glycol on the surface is removed, and dried under normal pressure to obtain functional nanocomposite films. Figure 2a The SEM photo of the nanocomposite film with infrared absorption function obtained in this embodiment is shown, and other parameters are shown in Table 1.

Embodiment 2

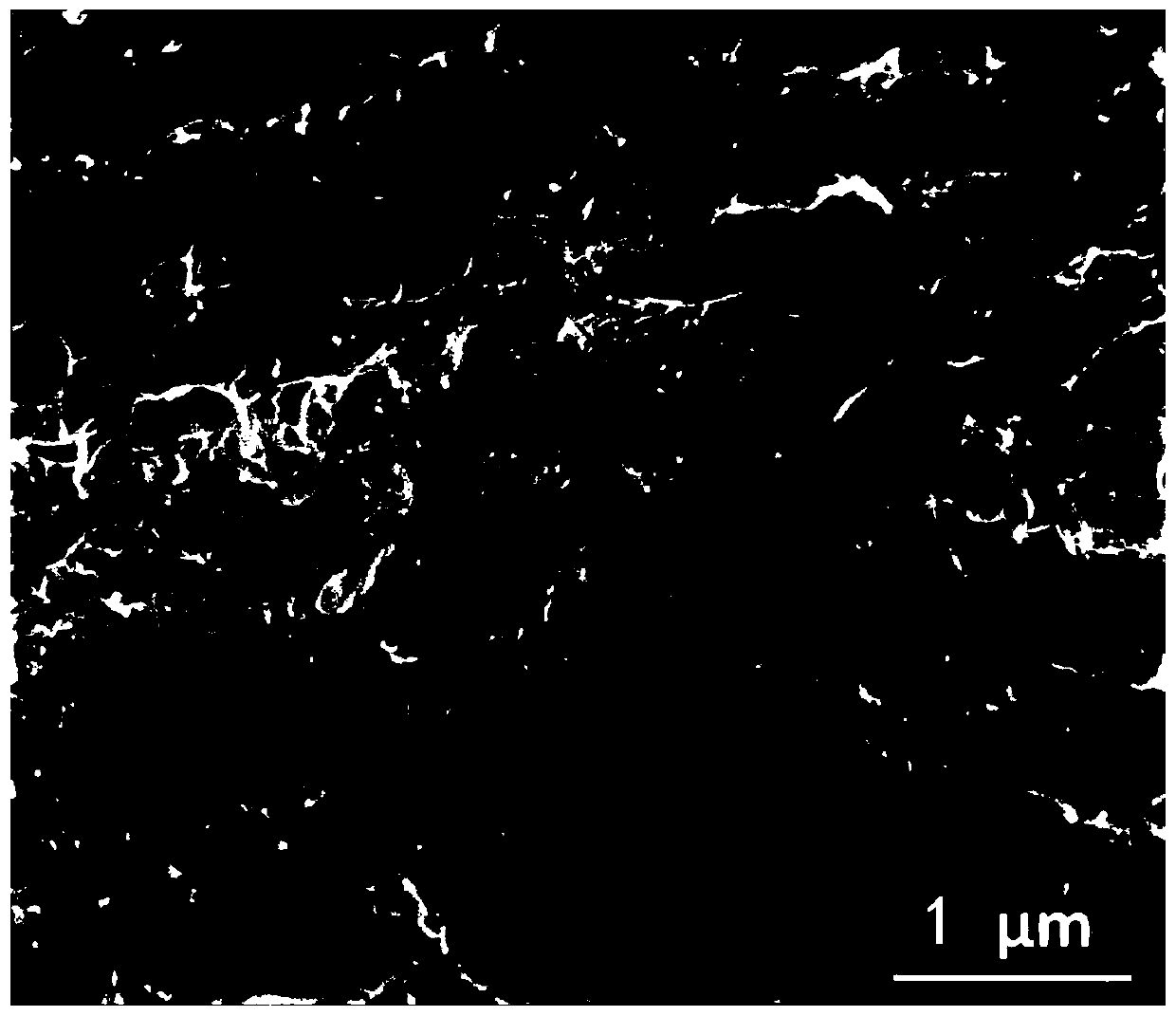

[0046] Prepare an aqueous solution of cetyl alcohol with a mass fraction of 50%, with a thickness of 500 μm, a porosity of 95%, and a density of 29 mg / cm 3 1. The aramid nanofiber porous film with a thermal conductivity of 0.036W / m·K is placed in an aqueous solution of cetyl alcohol, taken out after standing for 12 hours, the excess aqueous solution of cetyl alcohol on the surface is removed, and dried under normal pressure to obtain a film with infrared absorption function. nanocomposite films. Figure 2b The SEM photo of the nanocomposite film with infrared absorption function obtained in this embodiment is shown, and other parameters are shown in Table 1.

Embodiment 3

[0048] Heat stearic acid in an oven until it melts completely, the thickness is 1000μm, the porosity is 95%, and the density is 29mg / cm 3 , The aramid nanofiber porous film with a thermal conductivity of 0.036W / m·K is immersed in molten stearic acid, and placed in a vacuum oven at 80°C for 12 hours, then taken out, placed on filter paper, and then put back In a vacuum oven at 80°C, filter paper absorbs excess stearic acid on the surface of the film, takes it out of the oven after 6 hours, and obtains a nanocomposite film with infrared absorption function after cooling at room temperature. Figure 2c The SEM photo of the nanocomposite film with infrared absorption function obtained in this embodiment is shown, and other parameters are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com