Traction buffering device

A technology for traction buffering and tailstock installation, which is used in traction devices, transportation and packaging, railway car body components, etc., can solve the problems of reducing the safety and reliability of the device, short life of rubber buffers, and increasing production costs, and achieves a compact structure. , The effect of improving the service life and reducing the difficulty of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

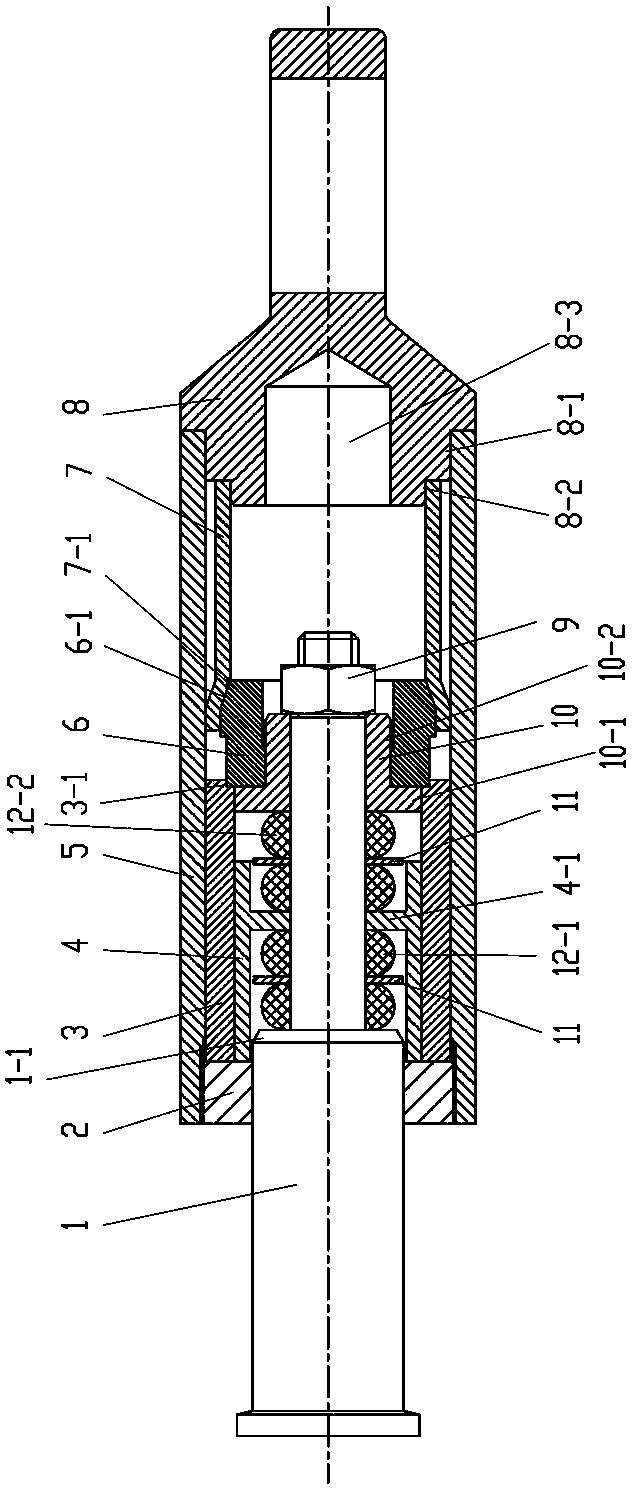

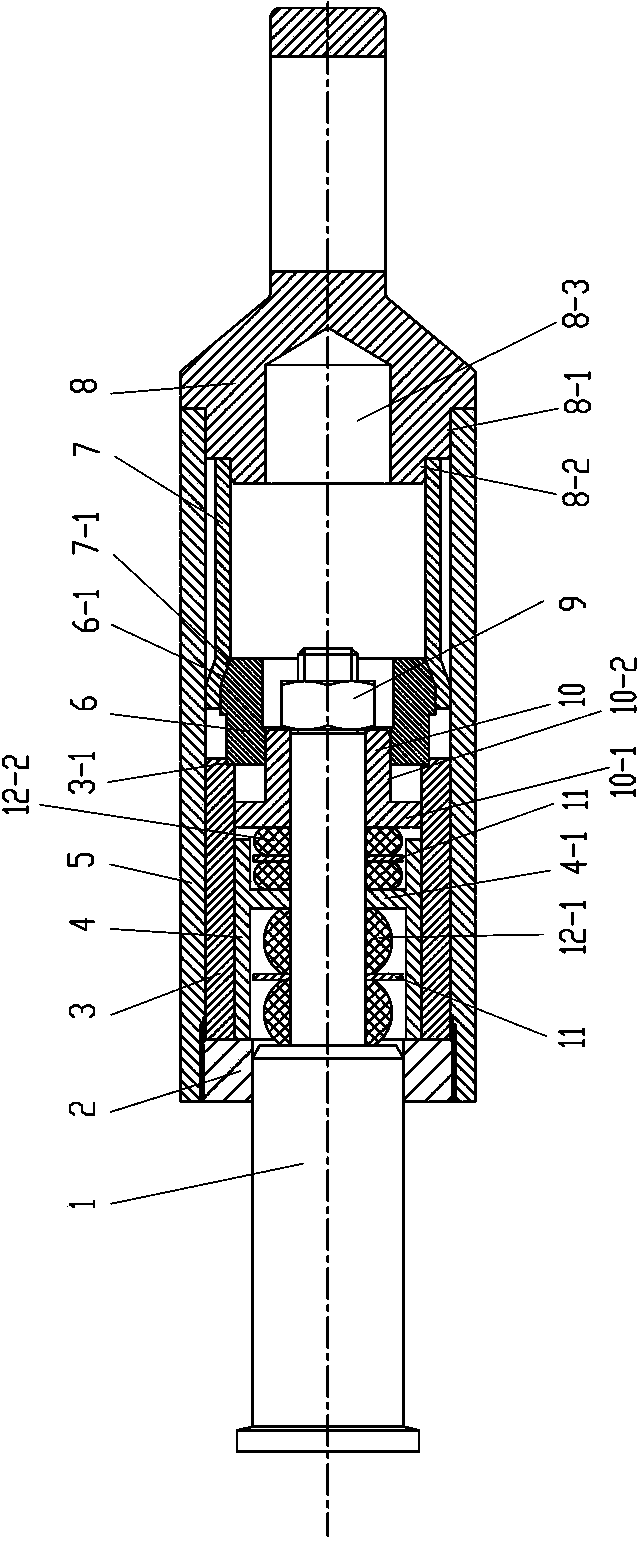

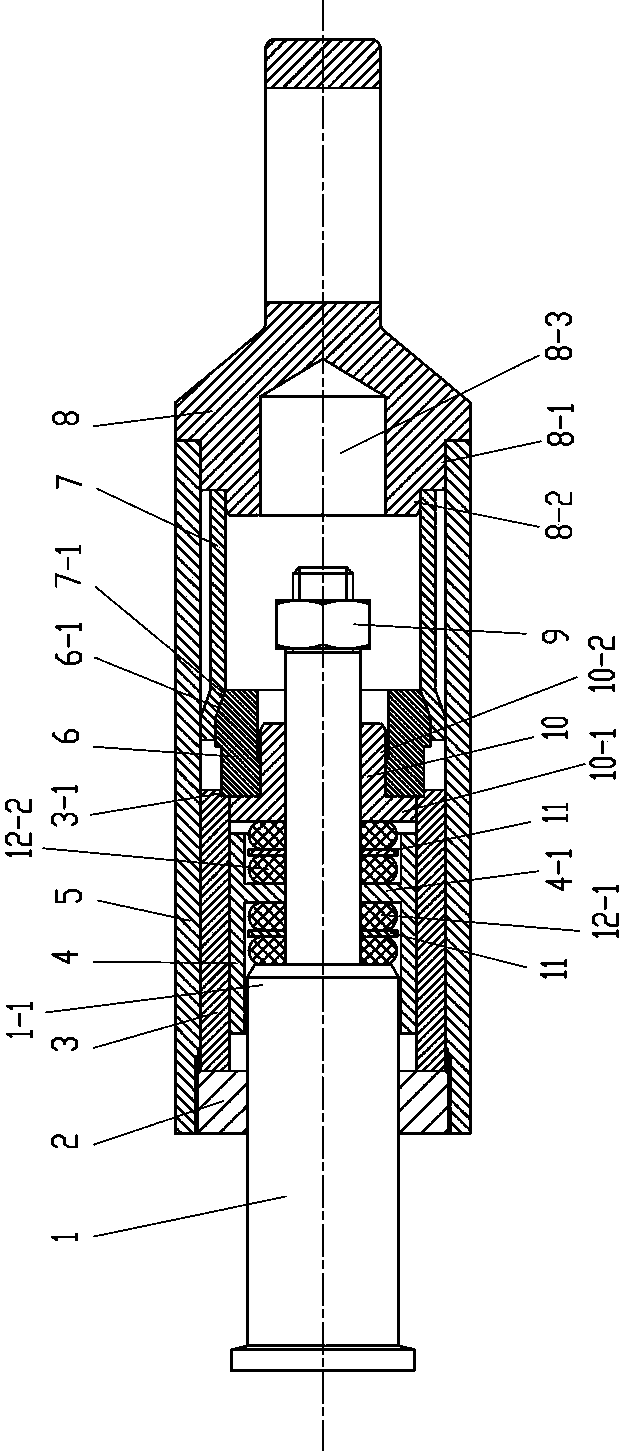

[0019] Such as Figure 1~4 As shown, the first embodiment of the present invention, a traction buffer device, includes an outer shell 5, a tailstock 8, a traction guide rod 1, an end cover 2, a guide partition 10, a lock nut 9 and at least two Elastomer, the two ends of the outer casing 5 are fixedly connected with the end cover 2 and the tailstock 8 respectively, one end of the traction guide rod 1 is inserted in the outer casing 5, and the other end extends out of the outer casing 5, and the guide The partition plate 10 and the elastic body 12-1, 12-2 are all loosely fitted on the rod body of the traction guide rod 1 located in the outer casing 5, and the inner sleeve 3, the sliding sleeve are also housed in the outer casing 5 4. The expansion ring 6 and the deformation tube 7, the left end of the inner sleeve 3 is in contact with the end cover 2, the sliding sleeve 4 is installed in the inner sleeve 3 and its outer circumference is slidably matched with the inner wall of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com