Overhead working truck leveling system

A high-altitude operation vehicle and leveling technology, which is applied in the direction of lifting devices, etc., can solve the problems of poor leveling effect and time-consuming process, and achieve the effect of continuous leveling process, fast dynamic response and easy promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

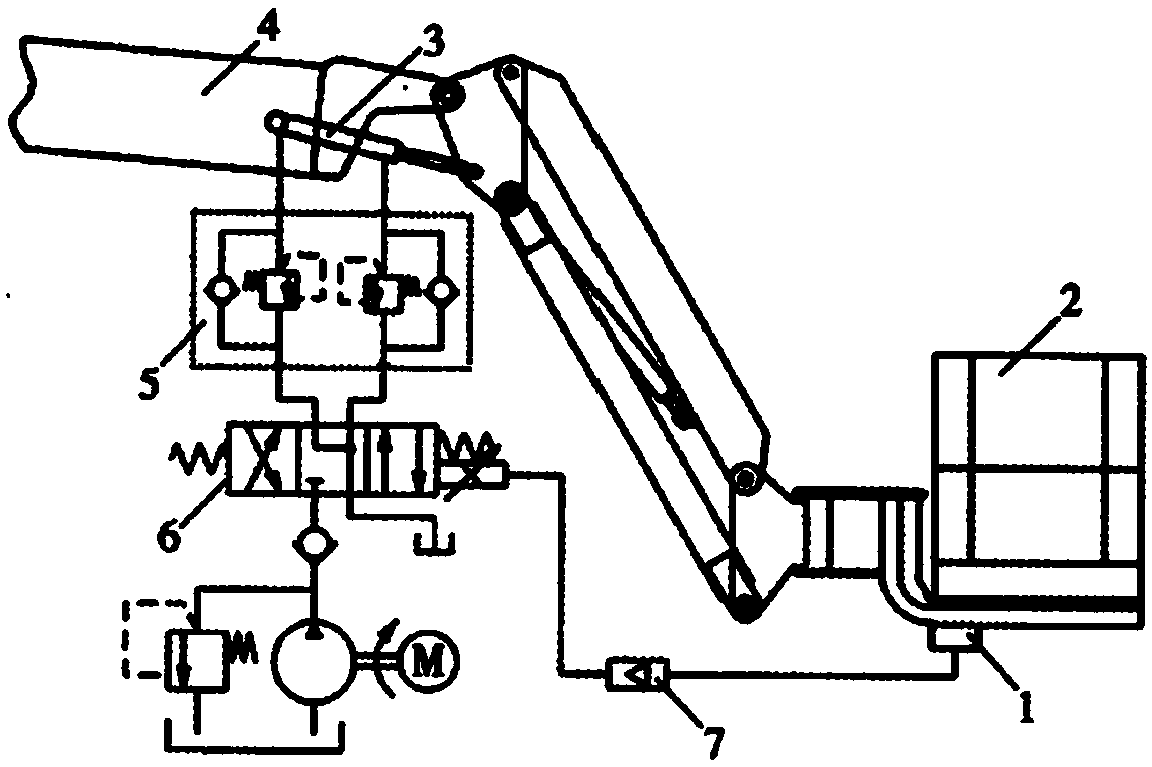

[0008] The aerial work vehicle leveling system of the present invention is composed of an angle sensor 1 connected in sequence, a controller 7, an electro-hydraulic proportional reversing valve 6, a balance valve 5, and a leveling hydraulic cylinder 3, wherein the angle sensor 1 is set at the working At the bottom of the platform 2, the leveling hydraulic cylinder 3 is connected with the arm rod 4.

[0009] The magnitude of the output signal of the angle sensor 1 is proportional to the inclination angle of the working platform 2 . When the boom 4 changes amplitude, the working platform 2 forms a certain angle with the horizontal plane, and the angle sensor 1 outputs a signal of a corresponding magnitude. After being processed by the controller 7, it is input to the electro-hydraulic proportional reversing valve 6 by the driving circuit. The spool of the electro-hydraulic proportional reversing valve 6 is displaced to output pressure oil. The flow rate of the pressure oil is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com