Traction gear of tentering setting machine

A stenter setting machine and traction device technology, applied in textiles and papermaking, fabric surface trimming, fabric elongation, etc., can solve the problems of space occupation, installation difficulties, and no adjustment mechanism for guide rollers, etc., to reduce height and reduce Occupation of space, convenient and accurate adjustment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

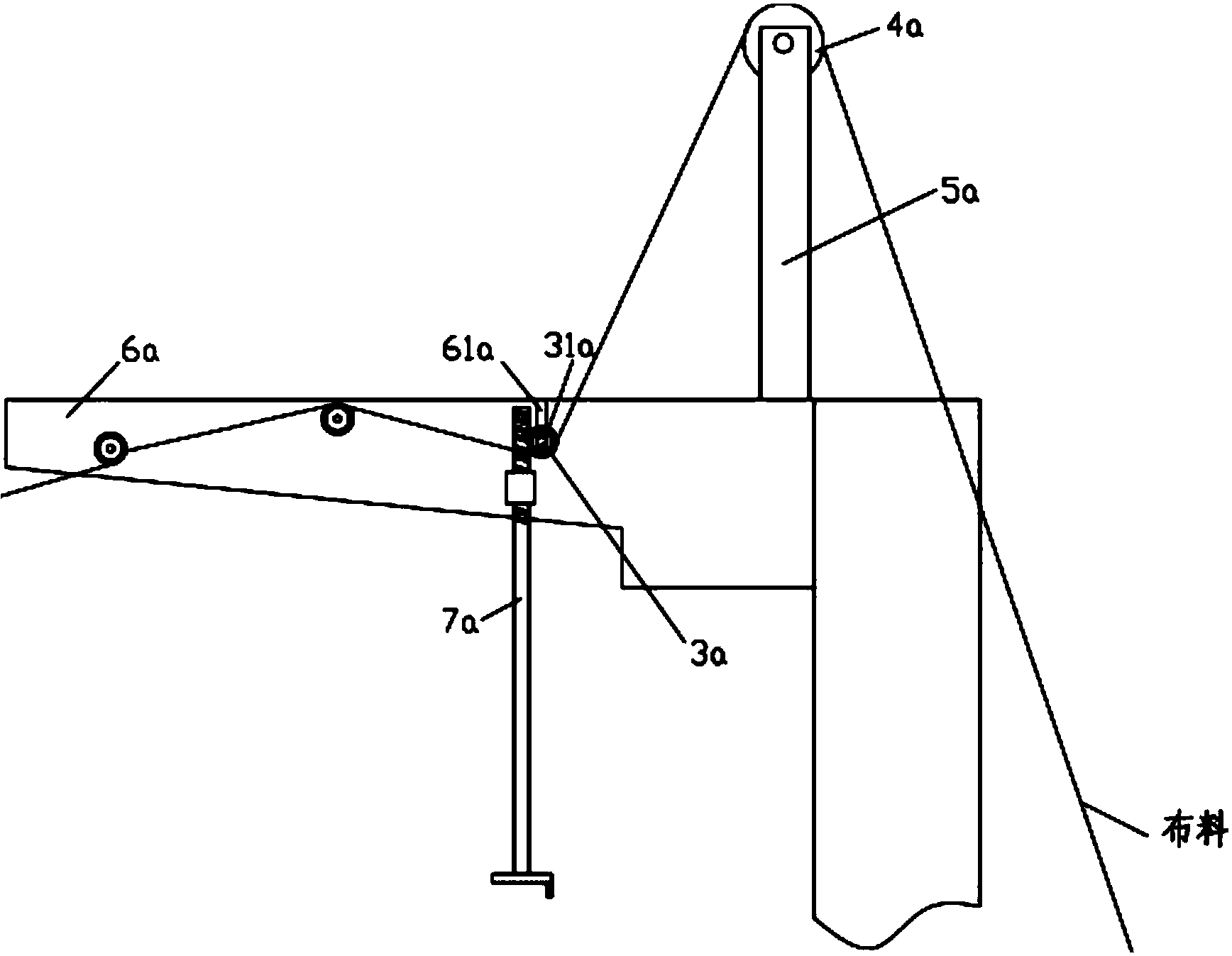

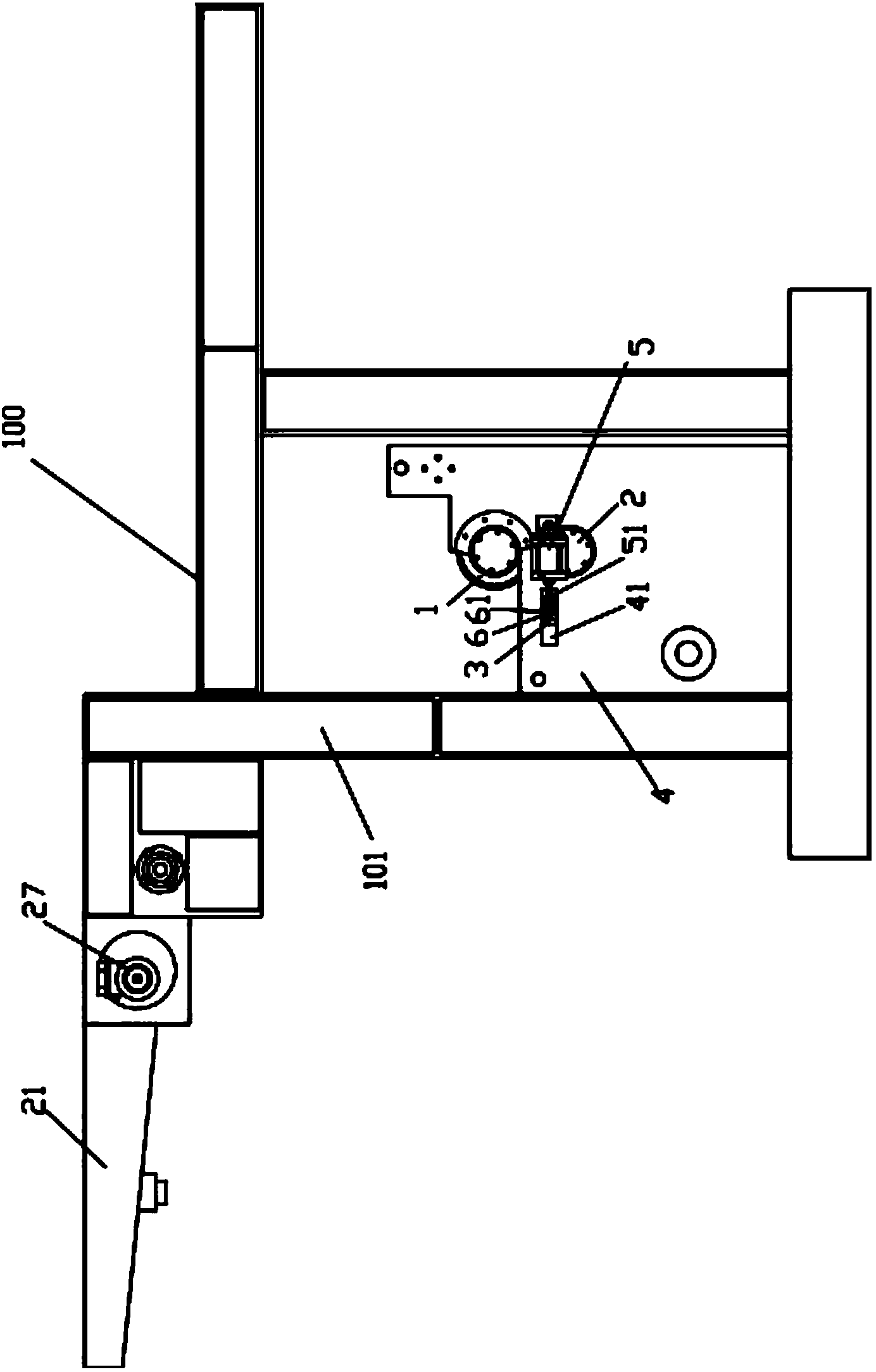

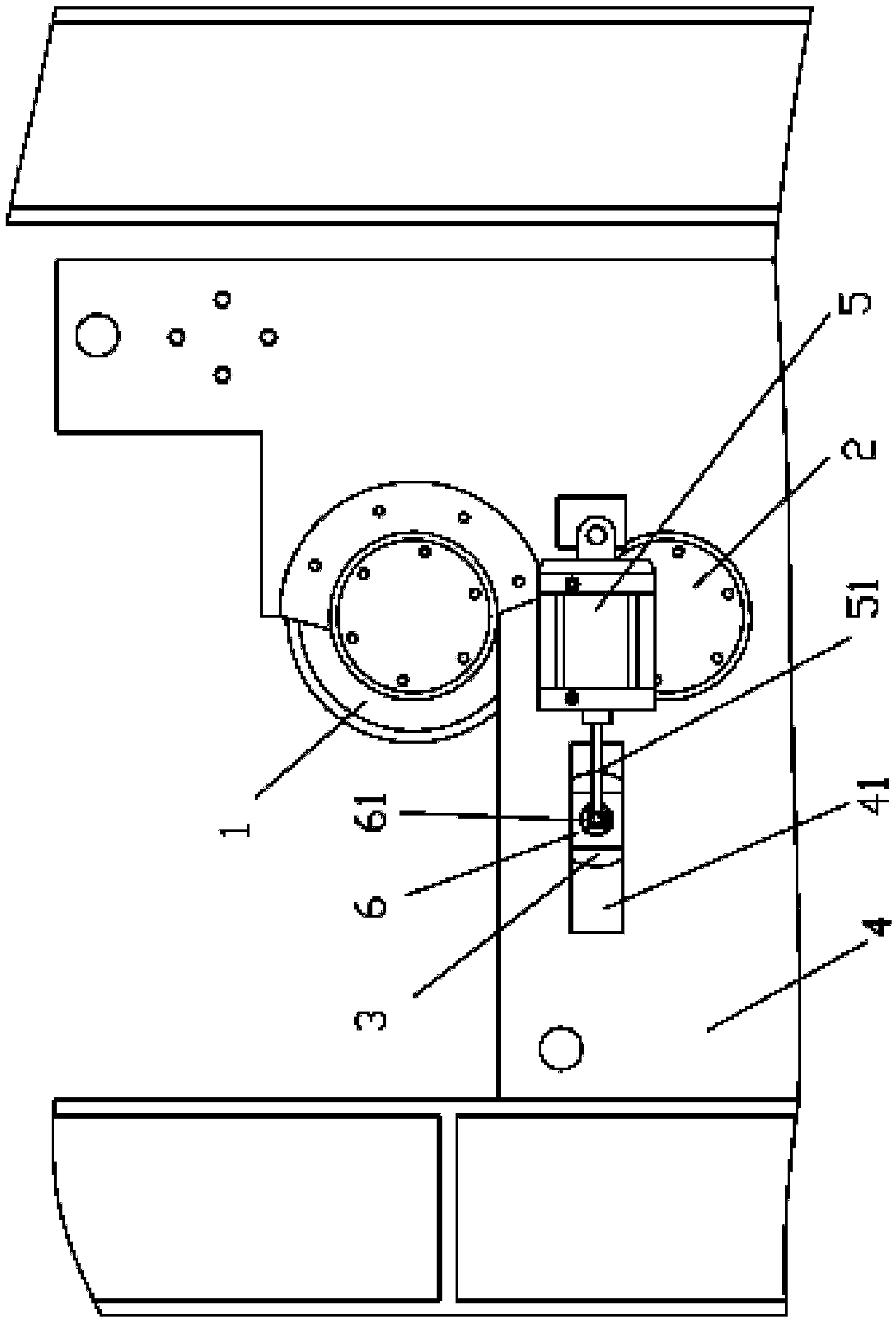

[0022] Example: see Figures 2 to 9 As shown, a drawing device of a stenter setting machine includes a frame 100, an open-width cloth feeding device 20 and a rolling device 10. The structure of the open-width cloth feeding device 20 is that the connecting beam 21 is fixed on the front pillar 101 of the frame 100 On the upper part, the first cloth guide roller 22 and the second cloth guide roller 23 are hinged between the two connecting beams 21, and the connecting beams 21 on both sides between the first cloth guiding roller 22 and the second cloth guiding roller 23 are fixed There are push cylinders 24, and the push rods 241 of two push cylinders 24 are hinged at the two ends of the cloth guide roller 25 in the middle; Both ends of the roll 3 are arranged on the two side plates 4 of the frame 100, the guide roll 3 is in front of the lower roll 2, the two side plates 4 are respectively fixed with a cylinder 5, and one end of the push rod 51 of the cylinder 5 is hinged on the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com