Transmission line breakage detection device

A technology of power transmission wire and detection device, which is applied in the direction of measurement device, measurement of electricity, measurement of electric variables, etc., can solve the problems of potential safety hazards, breakage, heavy workload, etc., and achieve the effects of simple and reliable device, accurate detection and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of the present invention will be further specifically described below through specific examples in conjunction with the accompanying drawings.

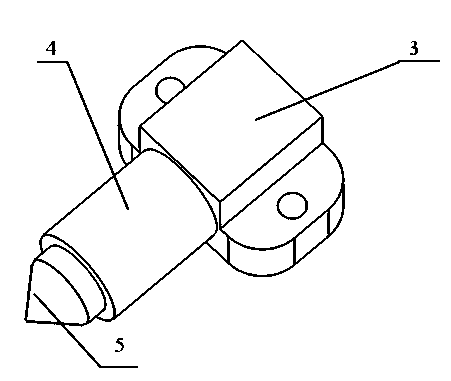

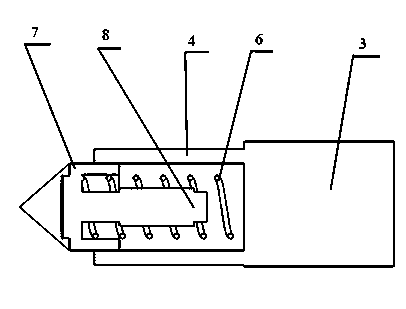

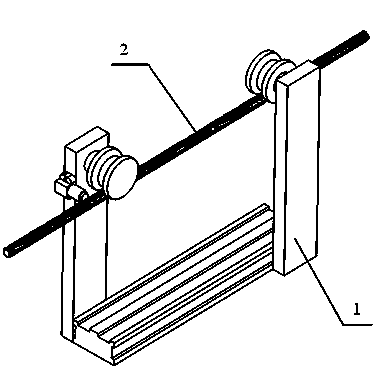

[0026] please see figure 1 , figure 2 and image 3 , the technical solution adopted in the present invention is: a broken strand detection device for transmission wires, comprising a base 3, a hollow guide tube 4, a conical probe tip 5, a spring 6, a cylindrical probe 7, a sensor 8 and a controller; the hollow guide One end of the tube 4 is fixedly installed on the side of the base 3, one end of the cylindrical probe 7 is provided with a thread, the cylindrical probe 7 is detachably installed with the conical probe tip 5 through the thread, and the other end of the cylindrical probe 7 is provided with a hollow aperture , one end of the spring 6 is placed in the hollow aperture of the cylindrical probe 7, the other end is placed in the hollow guide tube 4, the cylindrical probe 7 is telescopically insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com