Coupler buffer of railway truck

A railway wagon and buffer technology, which is applied in the direction of buffers, railway car body parts, traction devices, etc., can solve problems such as coupler buffer instability, coupler buffer damage, and prone to lateral movement, so as to avoid lateral movement, The effect of protecting from being destroyed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

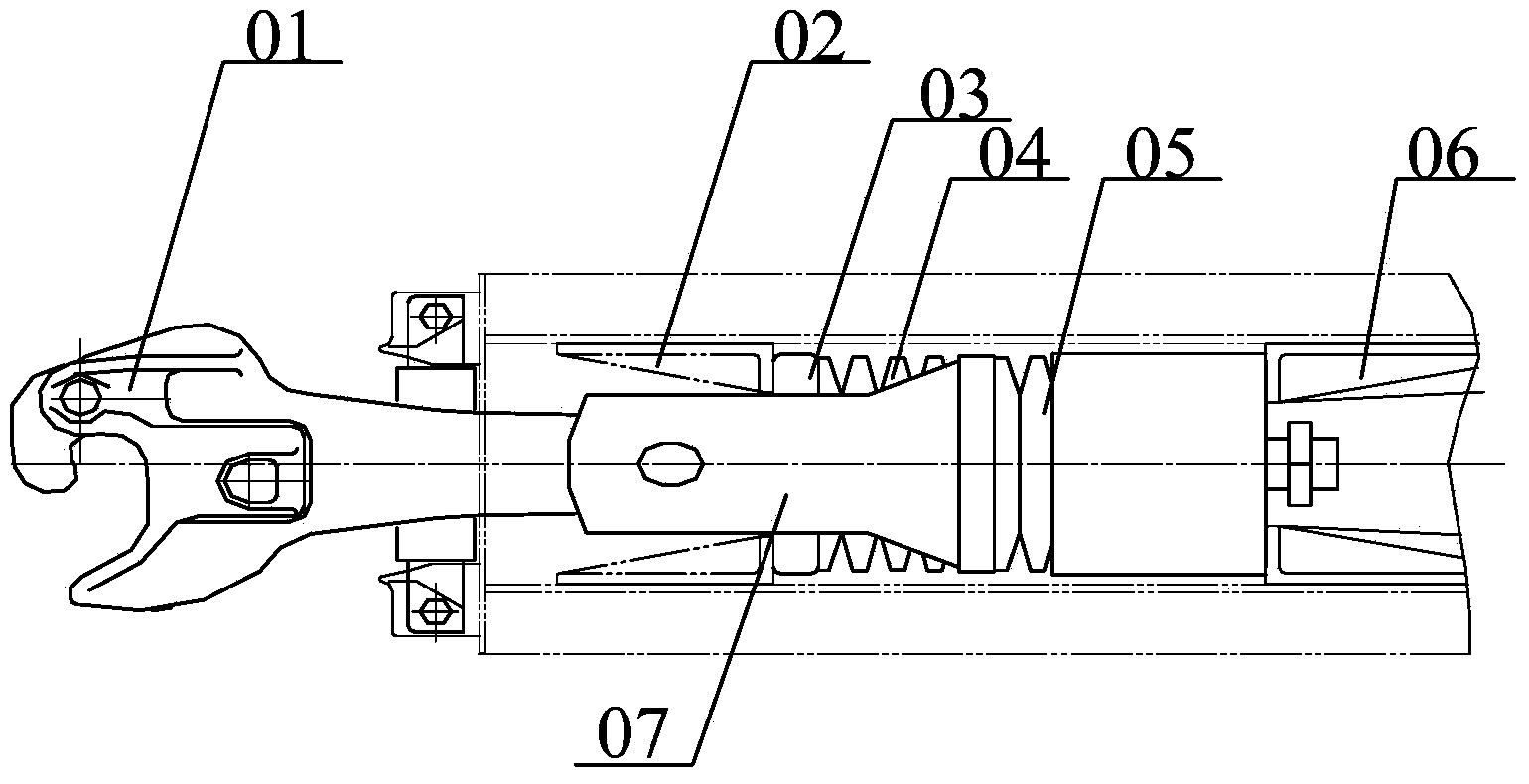

[0026] The core object of the present invention is to provide a coupler buffer for railway wagons to prevent the traction buffer unit in the coupler buffer from moving laterally while moving longitudinally, thereby avoiding damage to the coupler buffer.

[0027] In order to enable those skilled in the art to better understand the solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

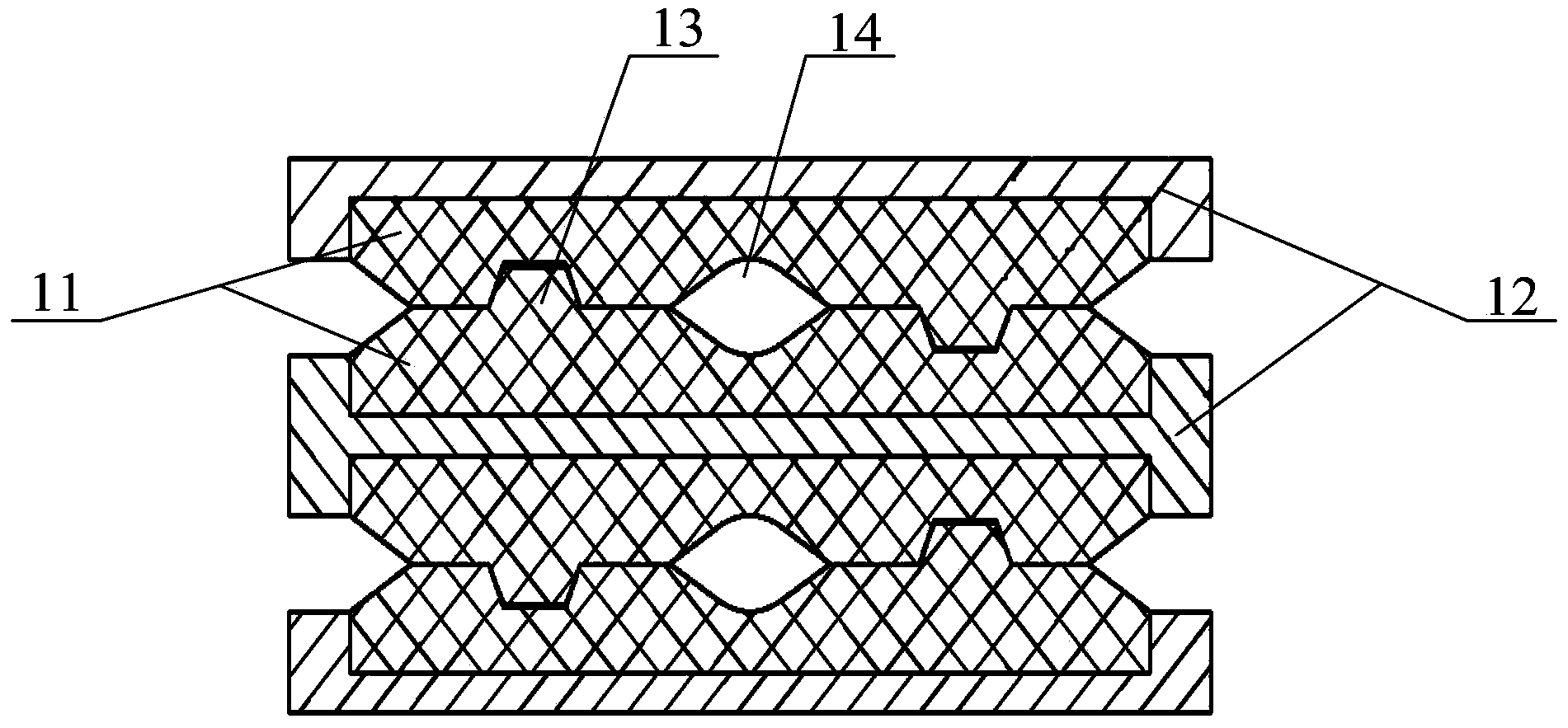

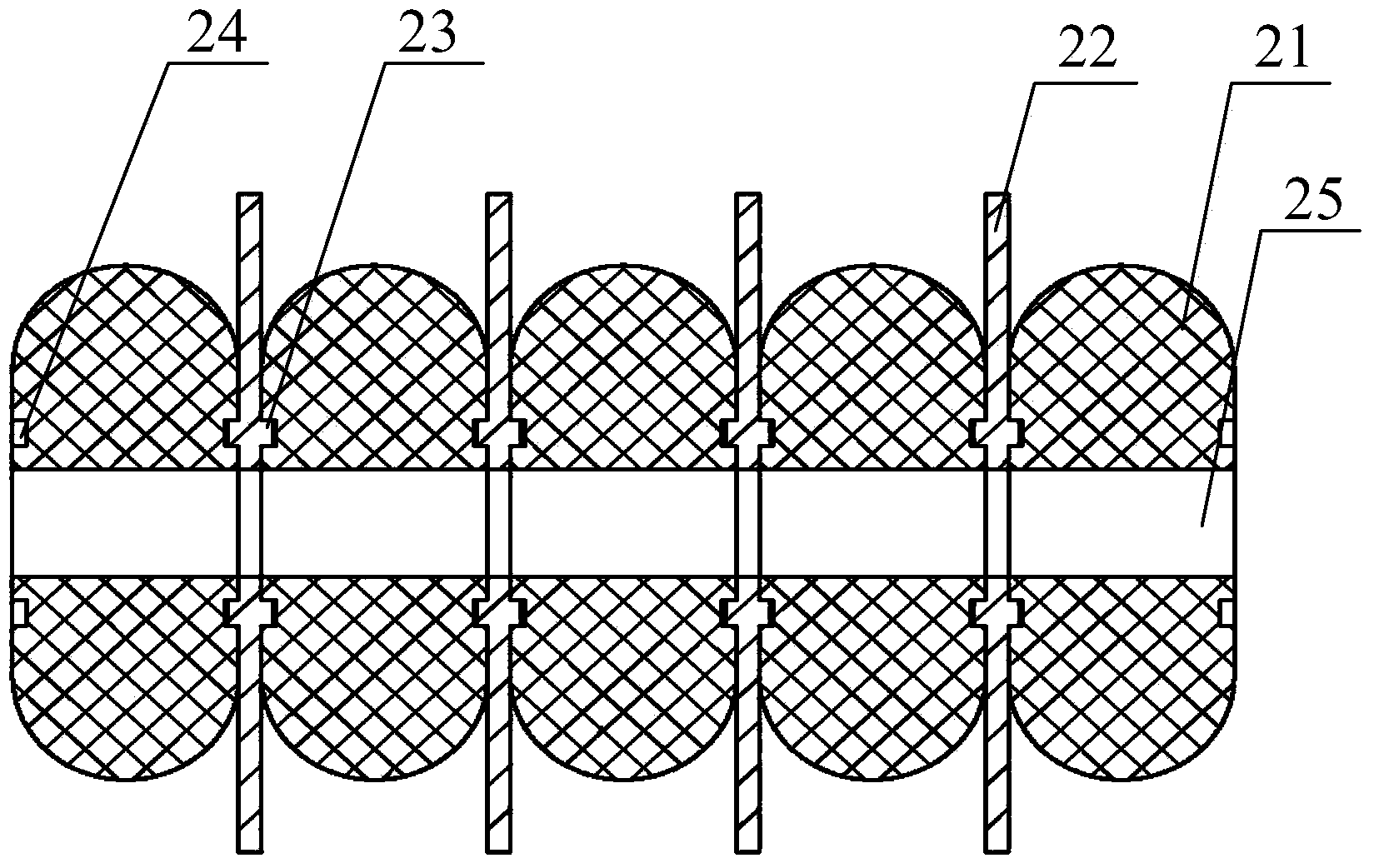

[0028] The railway freight car coupler buffer provided by the present invention includes a coupler, a coupler frame fixedly connected with the coupler, a traction buffer unit arranged inside the coupler frame, and a compression buffer unit connected to the bottom of the coupler frame. The core improvement point of the buffer compared with the prior art is that the traction buffer unit includes multiple pairs of superimposed traction buffer cells 11, and each pair of traction buffer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com