Composite intumescent flame retardant and application thereof to preparation of flame-retardant epoxy resin composite material

An intumescent flame retardant, compound intumescent technology, applied in the field of application in the preparation of flame retardant epoxy resin composite materials

Active Publication Date: 2014-01-22

QINGDAO UNIV OF SCI & TECH

View PDF3 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

According to "Iron-containing Compounds as Flame Retarding/Smoke-suppressing Additives for PVC" (Fire and Materials.12:109-113, 1988), iron phosphate, ferrocene, hydrated iron oxide, and ferric oxide are used in polychloride Ethylene

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

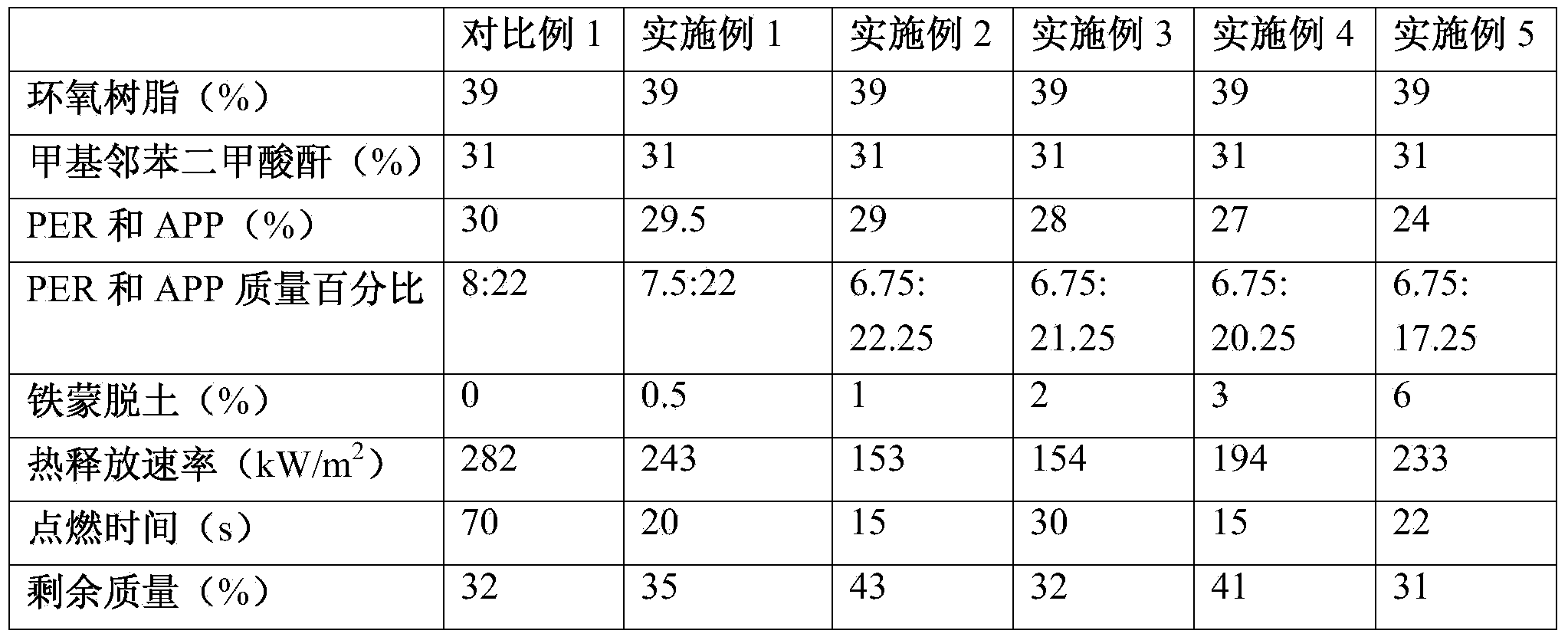

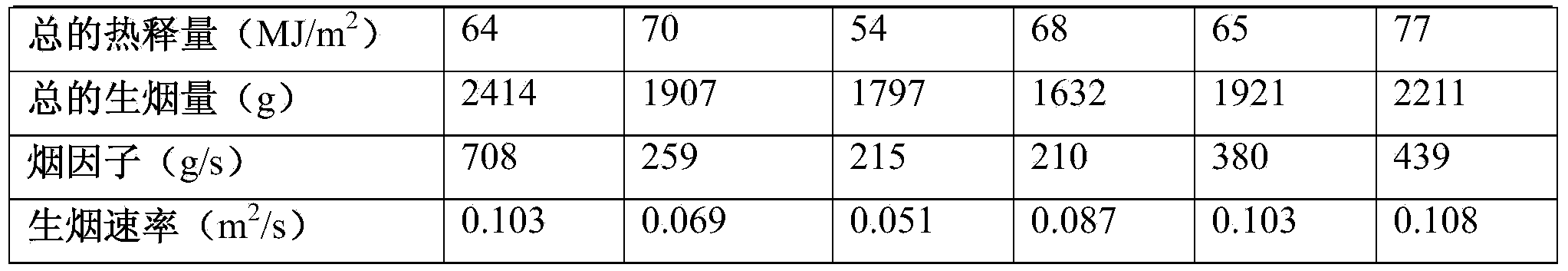

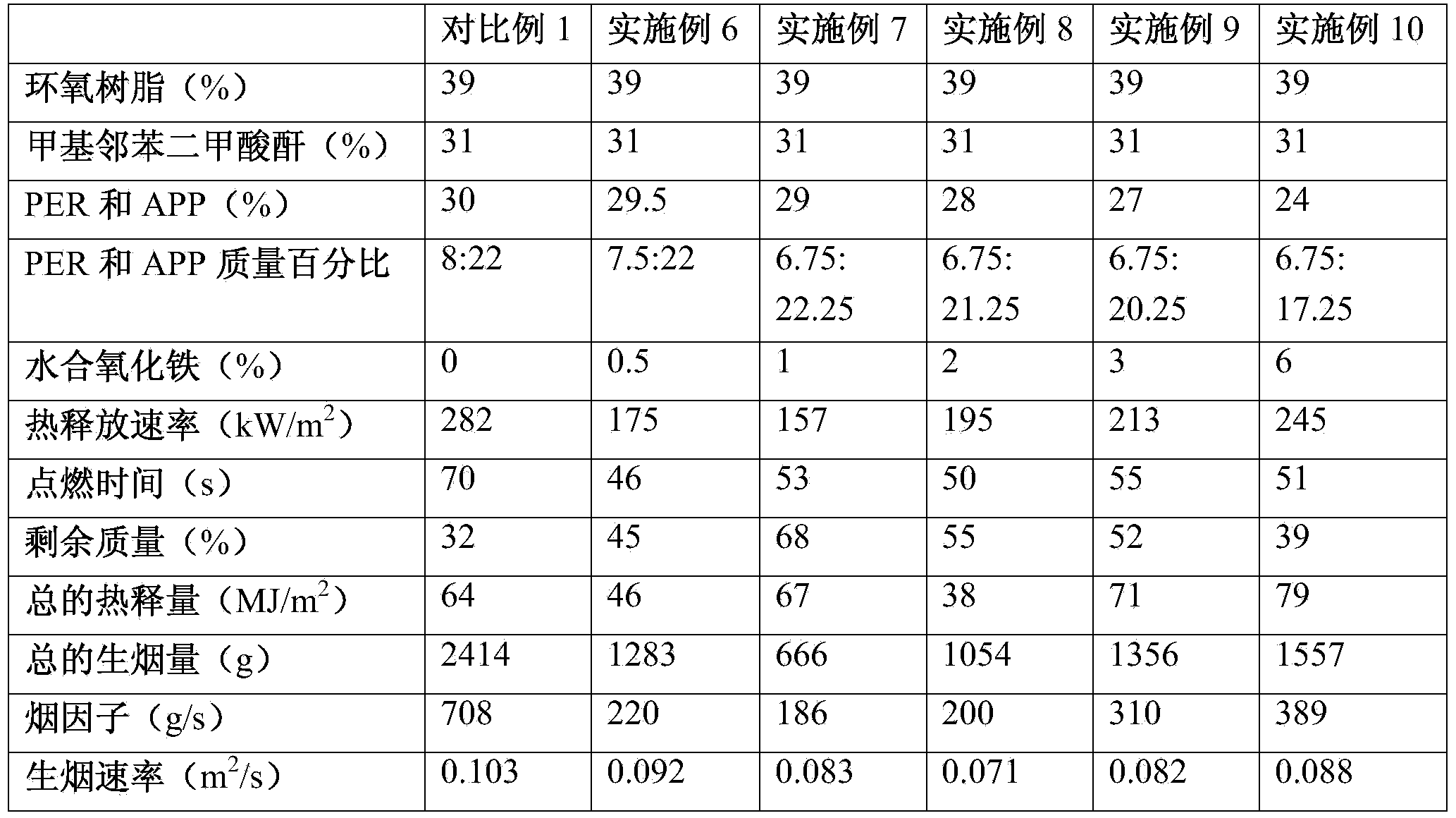

The invention relates to a composite intumescent flame retardant and an application thereof to the preparation of a flame-retardant epoxy resin composite material. The composite intumescent flame retardant comprises an intumescent flame retardant and an iron compound which are in the mass ratio of (24-29.9): (0.1-6). The composite intumescent flame retardant has the beneficial effects that the heat release speed, total heat release, smoke generation speed, total smoke generation quantity and smoke factor of an intumescent flame retardant epoxy resin composite material are remarkably increased by the addition of the flame retardant and the iron compound, and the residual mass of carbon residues is greatly increased; compared with a pure epoxy resin sample, an iron compound and intumescent flame retardant added sample has the advantages that the condition that the specific light density is reduced within shorter time proves that the intumescent flame retardant added sample is decomposed at the early stage so as to be beneficial to intumescence and flame retardance.

Description

technical field [0001] The invention belongs to the technical field of flame-retardant modification of epoxy resin, and in particular relates to the compounding of iron compound and expansion type flame retardant and its application in the preparation of flame-retardant epoxy resin composite material. Background technique [0002] According to "Synthetic Adhesives Series" (edited by Zheng Ruiqi and Yu Yunzhao, Chemical Industry Press, 1985), epoxy resin is an important class of thermosetting resin and the most widely used matrix resin in polymer composite materials. Epoxy resin has the advantages of excellent bonding performance, wear resistance, mechanical performance, electrical insulation performance, chemical stability, high and low temperature resistance, low shrinkage, easy processing and low cost, etc., but its flammability is limited its wider application. According to "Development of Flame Retardants and Application in Plastics" (Plastic, 31:11-15, 2002), tradition...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L63/00C08K13/02C08K5/521C08K5/5333C08K5/527C08K3/32C08K5/053C08K5/3492C08K3/34C08K3/22C08K5/56

Inventor 陈希磊刘磊焦传梅

Owner QINGDAO UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com